6

TABLE OF CONTENTS

Safety precautions

.........................................................

7

About storage management and handling

...................................

10

1. GENERAL DESCRIPTION.............................. 1-1

1.1 Preparation before Production.............................................................................. 1-2

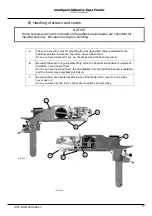

1.2 Exterior Features .................................................................................................. 1-3

1.3 Switch and LED Features..................................................................................... 1-5

1.4

Model and Its Target Components ....................................................................... 1-6

2. ATTACHING/DETACHING THE ADHESIVE

TAPE FEEDER, SETTING THE TAPE, CHECKING

THE COMPONENTS ........................................... 2-1

2.1 How to Attach/Detach the Adhesive Tape Feeder ............................................... 2-2

2.1.1 How to Attach the Adhesive Tape Feeder.......................................................................................... 2-2

2.1.2 How to Detach the Adhesive Tape Feeder ........................................................................................ 2-4

2.2 Setting the Tape ................................................................................................... 2-5

2.2.1 How to Set the Tape........................................................................................................................... 2-5

2.2.2 How to Detach the Bottom Tape ...................................................................................................... 2-11

2.3 Checking the Components ................................................................................. 2-12

3. CLEANING ...................................................... 3-1

3.1 Cleaning the Tape Paths ...................................................................................... 3-2

3.2 Cleaning the Collectively Changing Truck............................................................ 3-3

INDEX

IATF-E-OMA00-A02-00

Summary of Contents for CM402 Series

Page 2: ......

Page 5: ...5 MEMO IATF E OMA00 A01 00 ...

Page 8: ...8 WARNING IATF E OMA00 A03 00 ...

Page 9: ...9 CAUTION IATF E OMA00 A03 00 ...

Page 14: ...14 MEMO IATF E OMA00 A04 00 ...