4

INSTALLATION (CONTINUED)

•

Green (or green and yellow) conductor in the cord is the

grounding wire. Never connect the green (or green and yellow)

wire to a live terminal.

•

Many cover plate screws, water pipes and outlet boxes are not

properly grounded. To ensure a proper ground, the grounding

means must be tested by a qualified electrician.

EXTENSION CORDS

•

The use of any extension cord will cause some drop in voltage

and loss of power.

•

Wires of the extension cord must be of sufficient size to carry

the current and maintain adequate voltage.

•

Running the unit on voltages which are not within ±10% of the

specified voltage may cause overheating and motor burn-out.

•

Use the table to determine the minimum wire size (A.W.G.)

extension cord.

•

If the extension cord is worn, cut or damaged in any way,

replace it immediately.

EXTENSION CORD LENGTH for Model 82082A

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.W.G.

Up to 25 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

NOTE: Using extension cords over 25 ft. long is not recommended.

EXTENSION CORD LENGTH for Model 82102A

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A.W.G.

Up to 25 ft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

NOTE: Using extension cords over 25 ft. long is not recommended.

ELECTRICAL CONNECTIONS

WARNING:

All electrical connections must be performed by a

qualified electrician. Make sure tool is off and disconnected from

power source while motor is mounted, connected, reconnected or

anytime wiring is inspected.

•

Grinder is prewired at the factory for 220 volt, 3-phase

operation. See Figure 2 for wiring diagram.

•

Grinder can be wired for 440 volt, 3-phase operation.

See Figure 2 for wiring diagram for 440 volt.

•

Test grinder to be sure grinding wheels rotate downward

toward tool rests. Switch any two leads to reverse rotation

if needed.

OPERATION

WARNING:

Always wear safety glasses complying with United

States ANSI Z87.1 (shown on package) before commencing power

tool operation.

•

Keep a steady, moderate pressure on the work and keep it

moving at an even pace for smooth grinding.

•

Pressing too hard overheats the motor and prematurely wears

down the grinding wheels.

•

Note the original bevel angle on the item to be sharpened and

try to maintain that angle. Sharpening a cutting edge requires

removing burrs from edge.

•

Deburring edge is done best by using the grinder to pull burr

from edge across the bevel angle.

•

The grinding wheel should rotate into object being sharpened.

•

Dip work into a coolant regularly to prevent overheating.

Overheating can weaken metals.

MAINTENANCE

•

As wheels wear, tool rests should be positioned closer to the

face of the wheels.

•

The gap between the wheel and the tool rest should not be

greater than

1

/

16

”. When the wheels are worn to the extent that

the

1

/

16

” maximum gap cannot be maintained, the wheels

should be replaced.

•

Replacement wheels should have a minimum rated speed of at

least 3600 RPM for 82082A and 1800 RPM for 82102A.

•

Maximum wheel diameter for 82082A is 8”, and 10” for 82102A.

•

To loosen nuts holding the wheels, disconnect power and push

a wood wedge between the tool rest and the wheel to keep

the shaft from turning. The threads on the right side of the

grinder (facing unit) are right hand; threads on the left side are

left hand. Tighten nuts securely before operating the grinder.

•

For grinding efficiency, wheels should be dressed periodically,

especially if they become clogged from grinding soft metals.

Palmgren Operating Manual & Parts List

82082A & 82102A

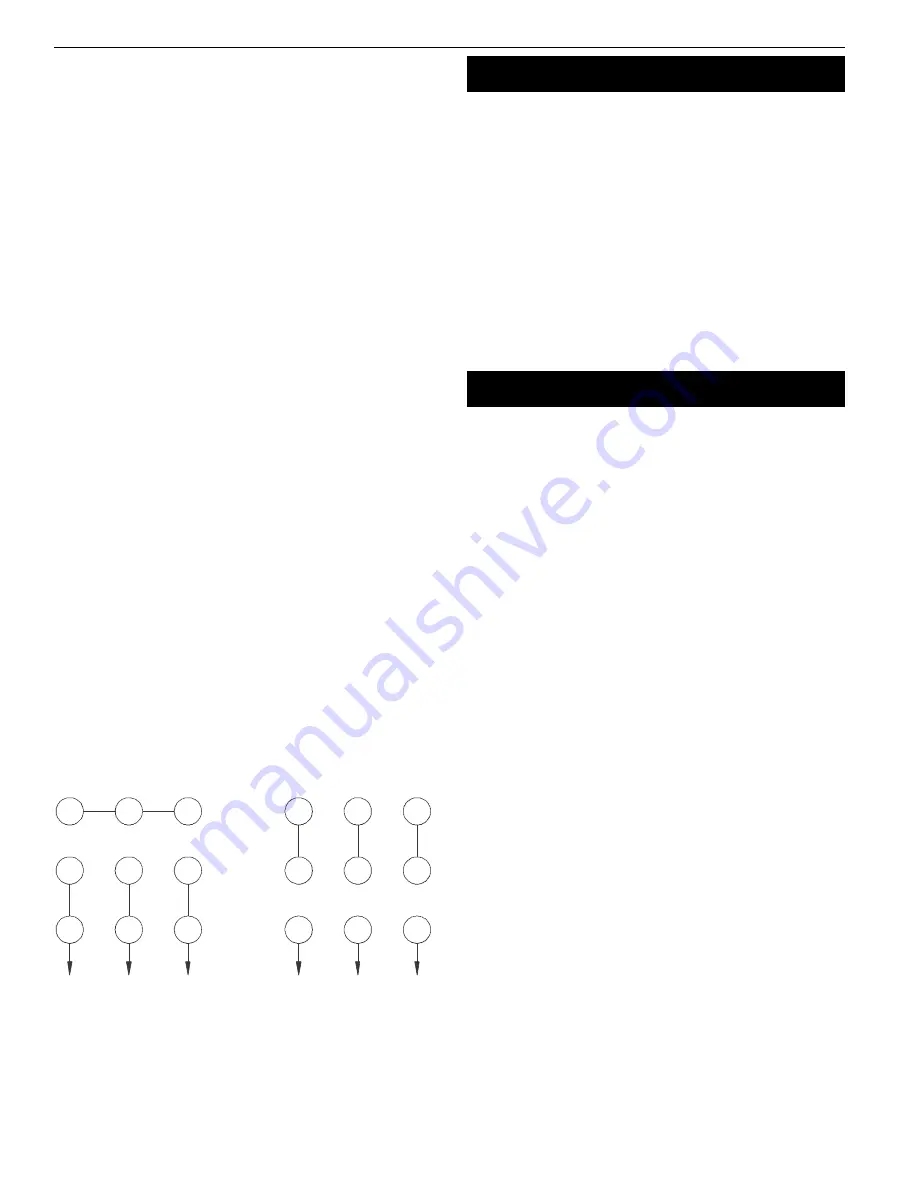

Figure 2 – Wiring Diagram

VOLTAGE CHANGE DIAGRAM

DISCONNECT FROM SUPPLY CIRCUIT BEFORE OPENING

220 VOLTS

440 VOLTS

4

1

7

8

2

3

9

6

5

4

1

7

8

2

3

9

6

5