5

Palmgren Operating Manual & Parts List

80110A

OPERATION (CONTINUED)

•

On units equipped with the Laser-Guide attachment, repairs

shall only be carried out by the laser manufacturer or autho-

rized agent.

•

Laser Warning label: Max output <5mW DIODE LASER: 630-

660nm, Complies with 21CFR 1040.10 and 1040. 11.

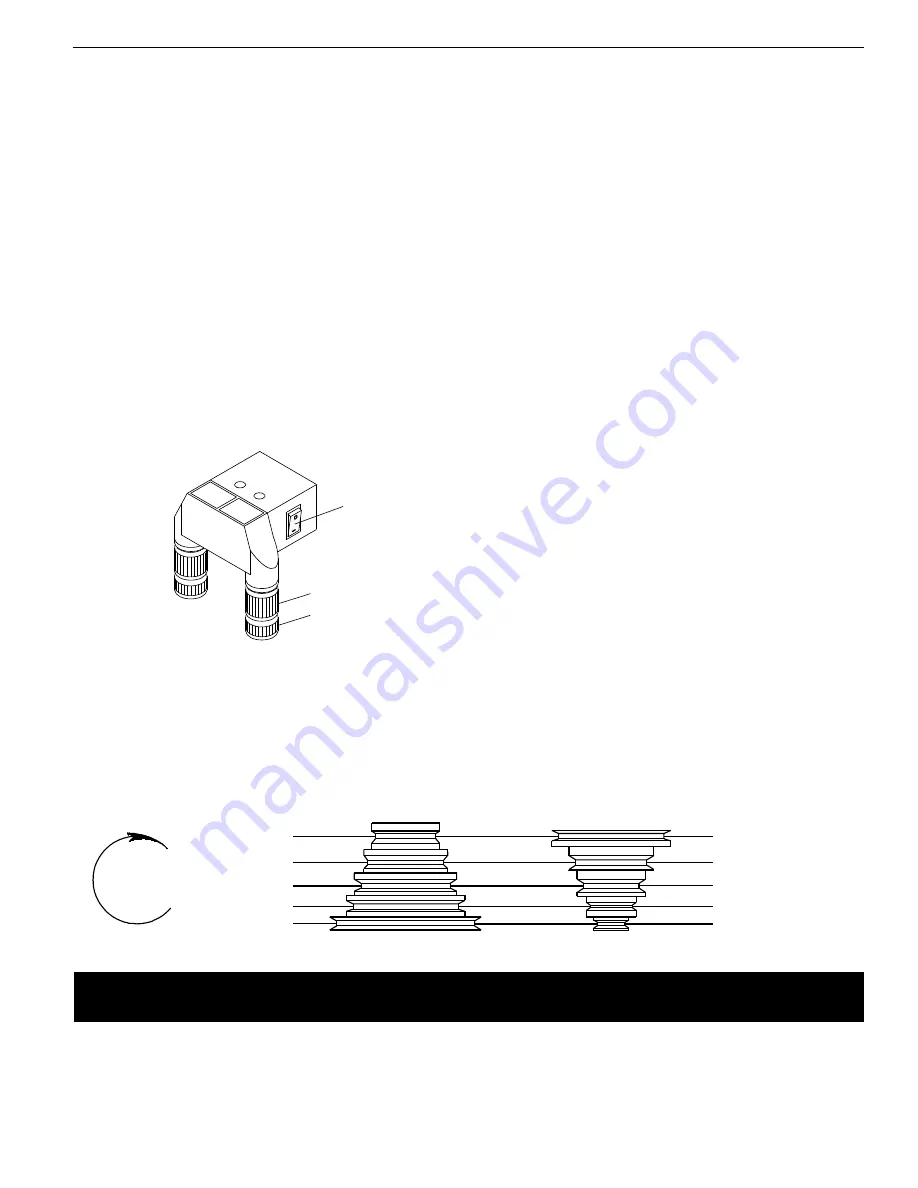

ADUSTING THE LASER LINES

Refer to Figure 4.

Check the laser beam alignment to ensure the intersection of the

laser lines precisely at the spot where the drill bit meets the work-

piece. If it is not, the laser lines should be adjusted using the laser

adjustment knobs located on the opposite sides of the head

assembly.

•

Mark an “X” on a piece of scrap wood.

•

Insert a small drill bit into the chuck and align its tip to the

intersection of the lines of the “X”.

•

Secure the board to the table.

•

Turn on the laser and verify the laser lines align with the “X” on

the workpiece.

•

If the laser lines do not align, loosen knobs on each side of the

laser module and rotate the lasers until the lines meet in the

center of the “X”. Retighten the knobs to secure.

NOTE: Check and adjust the laser beam alignment every time the

drill press table is raised or lowered to a new position.

SPEED ADJUSTMENTS

Refer to Figures 5 and 7.

WARNING:

Be sure drill press is turned off and is disconnected

from power source before adjusting speeds.

•

To change spindle speed, loosen motor lock bolt (Ref. No. 5), on

the right side of the head and push the motor toward front of

drill press. This will loosen the belt and permit relocating the

belt to the desired pulley groove for the required spindle speed

(See Figure 5).

•

After belt has been repositioned, push motor mount plate (Ref.

No. 6) to move motor toward rear of drill press and tighten

motor lock bolt.

•

Check belt for proper tension and make any final adjustment. A

belt is properly tensioned when light pressure applied to mid-

point of the belt produces about 1/2” deflection.

TABLE ADJUSTMENTS

Refer to Figure 6.

•

Height adjustments: To adjust table, loosen locking handle (Ref.

No. 12) and turn crank handle (Ref. No. 7) to desired height.

Immediately retighten table bracket locking handle.

•

Rotation of work table : Loosen table locking handle (Ref. No.

12) and rotate table to desired position and retighten handle.

•

Tilting work table: Loosen hex head bolt (Ref. No. 13). Tilt table

to desired angle up to 45° and retighten hex head bolt.

•

To obtain more distance between chuck and table, the work

table can be rotated 180° and base can be used as a work sur-

face. This permits drilling of larger objects.

•

Clamp table securely after adjustments have been made.

DEPTH STOP ADJUSTMENT

Refer to Figure 7.

•

To control drilling depth, loosen locking bolt (Ref. No. 11) on

quill feed assembly (Ref. No. 10). Rotate scale so desired depth

is indicated on scale next to the pointer. Tighten locking bolt.

Use this feature to drill more than one hole to the same depth.

•

Spindle can be locked in either fully or partially down position.

Loosen locking bolt (Ref. No. 11). Lower chuck to desired depth,

rotate scale fully clockwise and tighten locking bolt. Use this

feature to set up and align work.

MOUNT DRILL BIT

WARNING:

Be sure drill press is turned off and is disconnected

from power source before adjusting speeds.

•

Place drill bit in jaws of drill chuck.

•

Tighten chuck with drill chuck key. Be sure to tighten the chuck

using all three key positions on the chuck body and remove

chuck key.

•

Use only the self-ejecting chuck key (Ref. No. 40) supplied with

this drill press, or a duplicate key. Use of any other key might

allow start up with the key still in the chuck. An airborne key

could strike the operator and cause injury.

Spindle

Rotation

Spindle

Motor

Figure 5 – Spindle Speed Adjustment

Recommended Drill Size per Material for 5 Speeds

5

4

3

2

1

5

4

3

2

1

5-5

4-4

3-3

2-2

1-1

3100

2340

1720

1100

620

in/mm

5/16 7.9

3/8

9.5

5/8 15.9

7/8 22.2

1

1

⁄

4

31.8

in/mm

3/16 4.8

1/4

6.4

3/8

9.5

1/2 12.7

3/4 19.0

in/mm

11/64

4.4

7/32

5.6

11/32

8.7

15/32 11.9

11/16 17.5

in/mm

5/32

4.0

3/16

4.8

5/16

7.9

7/16

11.1

5/8

15.9

in/mm

7/64

2.8

1/8

3.2

1/4

6.4

11/32

8.7

1/2

12.7

in/mm

3/32

2.4

3/32

2.4

5/32

4.0

1/4

6.4

3/8

9.5

in/mm

1/16

1.6

1/16

1.6

1/8

3.2

3/16

4.8

5/16

7.9

in/mm

1/32 0.8

3/64 1.2

1/16 1.6

1/8

3.2

1/4

6.4

Belt

Location

RPM

Wood

Zinc Diecast

Alum. &

Brass

Plastic

Cast Iron

& Bronze

Steel

Mild &

Malleable

Steel Cast &

Med.

Carbon

Steel

Stainless &

Tool

Figure 4 – Laser Guide Assembly

Laser

Knob

Switch