ZENIT

TYPE TUBE RADIANT HEATER

User’s Manual

14

Flue pipe is not allowed to have a low point, it must be made of

Ø

100mm stainless steel or aluminium.The minimum ascent of flue

piping must be 2cm/m≈1°

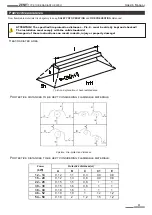

Type of the exhaust system:

• Leading of combustion products across the wall

• Vertical leading of combustion products

The lenght of exhaust system:

The lenght of the exhaust system depend on the allowed maximal lenght and the used length of the appliance�The total lenght of ex-

haust system can be the difference of allowed maximum lenght (m) as per types (ZENIT-12…58) and the used lenght – at the installa

-

tion – plus 6 m�

L

:Total lenght of exhaust system

L

max

:The allowed maximal lenght of appliance (it is defined as per types)

L

used

:The used lenght of appliance (at the installation)

L = L

MAX

- L

used

+ 6 [m]

The total lenght of exhaust system can be completed with 1pc 90° elbow without any correction.

In case of using more 90° elbows the following correction has to be considered:

Correction 1 pc 90° elbow = 1 m exhaust tube

(combustion products leading tube)

Namelly using more than one 90° elbow the lenght of exhaust system has to be proportionally reduced with the corrective value�

The exit module of exhaust system must be at least higher than 1 m from openings(sucking hole of vent etc�) of force-assisted ventilation

systems� The bottom side of exit opening must be minimum from 30 cm any kind of frontal wall-protruding�

ATTENTION! The installation of appliance must be only executed by qualified service or specialist

authorized by retailer. The 2 years guarantee of appliance can be ensured only in this case.

7.

Appliance operation

Following the switched on voltage the fan operates continuously assuring the 30 seconds prepurge time� This time period ensures the

three times air change of combustion volume in case of biggest appliance’s power�

When the pressure is suitable - after 30 seconds – the sparking happens and the solenoid valve opens in this way the gas catches fire.

In case during 5 seconds sparking(ignition) the continuous flame shape is stabilized, - and stable electrical signal is come back from the

electrode – the appliance operates and the green control lamp is lighting� During operation of appliance its automatic burner control con-

trols the condition of differential pressure switch and signals coming from the flame control continuously, and if the position of differential

pressure switch is changed – it is switched over from work position to rest – or the signal from the ionization flame control is interrupted

then it stops the gas supply of burner and the appliance gets into error position and red control lamp is lighting placed on the bottom side

of appliance�

8.

Appliance specification

Start, restart

Operation of automatic burner control ( HONEYWELL S4965R typ)

If the flame control of burner automation does not register flame during the safety time than repeats the all ignition procedure

maximum two times.

If in this time there is not registered flame then it stops the gas supply of burner and the appliance gets into error

position and red control lamp is lighting�

In case during burning process the pressure decreases under the permissible minimal

value on the positive side of air pressure(from the fan side),then automation prohibits:

- gas supply and fan stops

The appliance stands into error position and red control lamp is lighting�

Restart is possible after the switching off and on of mains voltage.

In case during burning process the pressure increases above the permissible maximum value on the negative side of air pressure switch

(from the burner tube side, eg�at combustion back),then it switches back to rest position and the automation prihibits�

- gas supply and fan stops

The appliance stands into error position and red control lamp is lighting�

Restart is possible after the switching off and on of mains voltage

�

Summary of Contents for ZENIT Series

Page 34: ...ADIANT HEATER User s Manual...