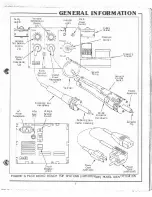

GENERAL INFORMATION

PARTS IDENTIFICATION

TABLE 1.

MICRO BENCH TOP SYSTEMS (MBT-100/100E) PARTS IDENTIFICATION

•

VARIABLE TEMPERATURE CONTROL (Jl)-provides varrable temperature

c

onirol ror

EJr..

tractor Handpiece Tip temperau,re.

•

INDICATOR LIGHT-amber ngnt 1ratcates Main Power sw,tcn 1s -oN-.

•

MAIN POWER SWITCH-

c

ontrols input power within Micro Bench Top System.

•

PRESSURE CONTROL-air control ror hot-alr Jet mode.

•

VACUUM FITTING-vacuum tlow

re,

solder removal.

•

OUTPUT POWER RECEPTACLE 1J1)-connects power rrom Micro Bench Top System to

Extractor Handptece.

•

VISIFILTER

™

-collects and prevents foreign sustances rrom entering the Motor/Pump

Assembly.

•

EXTRACTOR HANDPIECE-1001 used ror de.soldering, hot air pressure (blind side solder

removaQ and hot-air jet mode (removes solder connections and shrinks tubing)

fun

c

t ions.

{t--

•

VACUUM CONTROL SWITCH-Extra

c

tor Handpieca •ON/OFF" switch activa1e.s Moto(/Pump.

•

EXTR ACTOR TIP-heats and extracts solder lrom components.

•

HEATER ASSEMBLY -provides heat to Extraclor Handpiece Tip.

•

CUBBY HOLD

ER

-

conve

n

i

ently stores Extractor Handpiece.

•

EARTH GROUND TERMINAL-prcvides a

ground

between the M

i

cro

Bench Top Sys:em and

PCB, thus preventing

an

electrical charge rrom damaging sensitive components.

•

AC

POWER

RECEPTACLE -provides AC power to Mi

c

ro Bench Top System Imm AC outlet

through Power Cord.

•

VOLTAGE SELECTOR SWITCH-selects proper voltage which corresponds with input line

voltages. (NOTE: Switch must be placed in the proper position belore plugging in P'olver Cord).

•

POWER CORD-provides

main

power rrom AC outlet to AC Power R e

c

epta

c

le.

•

LINE FUSE (Ft)-provides overloaj protection for Micro Ben

c

h Top System.

•

CIRCUIT

BREAKER (CB1)-provic!es overload protection for Micro Bench Top System.

Figure 2 identifies the controls and indicators required lor operation on the Micro Ben

c

h Top

System(s) (MBT-100/lOOE) and the Extractor Handpiece. Refer to Table 1 and Figure 2 for location

and Identification of ea

c

h part.

4