INSTALLATION MANUAL - INSERT TITLE HERE, L1234

PG 4

INSTALLATION MANUAL - C44059 / C44061 / C44063 / C44065, L5855

PG 4

8

C44063 & C44065 KITS ONLY:

Under the hood, beside the fuel filter, locate the factory 3 pin

Weather- Pac connector on the driver side of the engine (

shown

by the arrow

). Remove the protective cap and install the mating

connector in the Pacbrake harness. Install the removed protective

cap on the unused connector on the Pacbrake harness - unless

you have a performance module connected to it. If so, it connects

to the Pacbrake connector.

NOTE:

Some 1999 model year trucks and all 1998½ will require

the use of a 3 pin triangular jumper harness to connect to the data

link connector. See schematic pertaining to your kit #, found on page

9-11. Proceed to Step 10.

9

C44061 KIT ONLY:

Locate the diagnostic connector under the dash on the drivers side.

Connect the male plug of the Pacbrake harness to the factory

diagnostic connector. Secure the Pacbrake connector to the

diagnostic connector using the supplied tie straps.

10

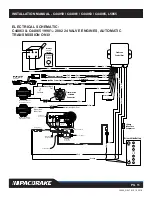

C44061, C44063 & C44065

Remove the air filter housing to access the passenger side firewall

and locate the PCM (

shown in fig 10A

). Remove the C2 and C3

connectors. Remove the plastic cover to access the wires. Pull back

the conduit to give access for attaching wires into the factory harness.

Use fig 10B as a guide to the pin locations.

C2 CONNECTIONS

Locate the orange/black wire in pin 11 of the C2 connector. Cut this

wire. Attach the brown wire of the Pacbrake harness to the PCM side.

Attach the orange wire to the harness side of the orange/black wire.

These connections are done using the supplied red heat shrinkable

butt connectors.

Locate the brown wire in pin 21 of the C2 connector. Cut this wire and

splice the blue wire of the Pacbrake harness into it using the supplied

red heat shrinkable butt connectors.

C3 CONNECTIONS

Locate the orange/white wire in pin 13 of the C3 connector. Cut this

wire and splice the yellow wire of the Pacbrake harness into it using

the supplied red heat shrinkable butt connectors.

Using the heat gun, heat the connectors to provide a water tight seal

on all heat shrinkable butt connectors. See the wiring diagram

pertaining to your kit #, found on page 9-11.

PCM AND TRANSMISSION CONNECTIONS

8

9

10

A

10

B

C1

C2

C3

C1

C2

C3

22

12

1

32

21

11

Powertrain Control

Module C2 (Diesel)

22

12

1

32

21

11

Powertrain Control

Module C3 (Diesel)

POWERTRAIN

MODULE C2

(DIESEL)

POWERTRAIN

MODULE C3

(DIESEL)