Automatic Welding Machine

4

droplets.

Do not allow water to enter the

inside of the machine.

►

Avoid welding in dusty or corrosive gas

environments.

►

Avoid gas welding in a strong air flow

environment.

►

A worker who has a pacemaker in-

stalled should consult a doctor before

welding.

Because the electromagnetic

field can interfere with the normal opera-

tion of the pacemaker.

Product description and specifi-

cations

Read all safety warnings and all

instructions.

Failure to follow the

warnings and instructions may result

in electric shock, fire and/or serious

injury.

Intended use

Semiautomatic inverter type direct current

welding machine (hereinafter referred to as

the product) is designed for welding using the

MIG / MAG methods (welding with electrode

wire in a shielded gas) and MMA (manual arc

welding with stick fusible covered electrodes).

The product can be used for welding various

types of metals.

Product features

The numbering of the components shown re-

fers to the representation of the power tool on

the graphic pages.

1. Polarity reversing cable

2. Torch connection socket

3. Power connector “+”

4. Power connector “-”

5. Fan

6. Power button

7. Connection for shielding gas

8. Power cable inlet

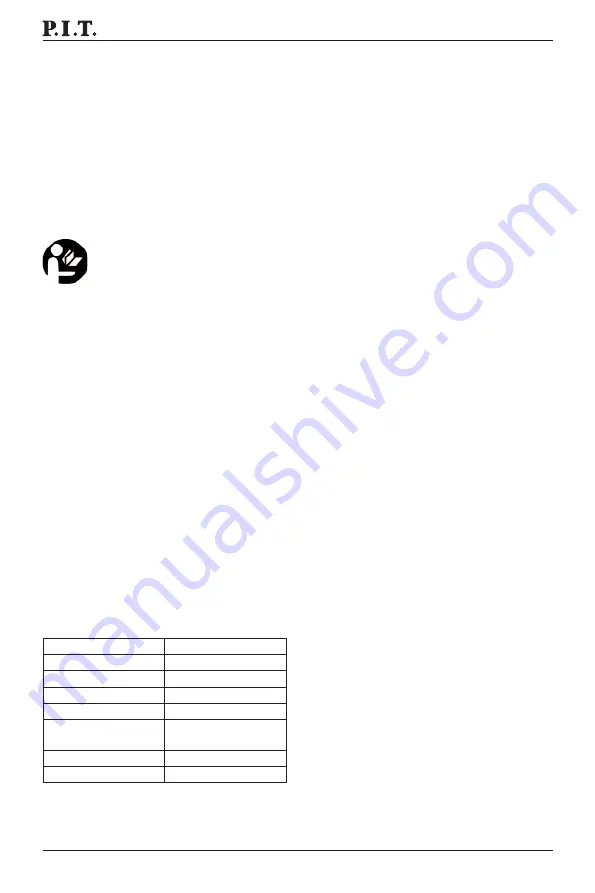

Technical data

Model

PMIG145-C1

3BUFEWPMUBHF

190-250 V~ / 50 Hz

3BUFEQPXFS

4000 W

Output current range

10-145 A

Wire diameter (MIG)

0.8-1.0 mm

Electrode diameter

(MMA)

1.6-3.2 mm

Duty cycle (DC)

25

˫

60%

Weight

7 kg

Contents of delivery

Automatic welding machine

1pc

Cable with electrode holder

1pc

Cable with grounding terminal 1pc

Torch cable

1pc

Welding shield

1pc

Hammer brush

1pc

Instruction manual

1pc

Note

The text and numbers of the instructions may

contain technical errors and typographical er-

rors.

Since the product is constantly being im-

proved, P.I.T. reserves the right to make

changes to the specifications and product

speci

fi

cations speci

fi

ed here without prior no-

tice.

Preparation for work

Place the machine on a flat surface. The

workplace must be well ventilated, the weld-

ing machine must not be exposed to dust,

dirt, moisture and active steam. To ensure

adequate ventilation, the distance from the

apparatus to other objects must be at least 50

cm.

ATTENTION!

To avoid electric shock, use

only electrical mains with a protective earth

conductor and grounded receptacles. DO

NOT alter the plug if it does not

fi

t into the out-

let. Instead, a quali

fi

ed electrician must install

an appropriate outlet.

Ensuring the safety of preparation

for work

Before turning on the product, set the switch

to the “0” position, and the current regulator to

the extreme left position.

Prepare for work:

– Prepare the parts to be welded;

– Provide adequate ventilation in the work-

place;

– Make sure that there are no solvent

vapors, flammable, explosive and chlo-

rine-containing substances in the air;

– Check all connections to the product; they

must be made correctly and securely;

– Check the welding cable, if damaged it

must be replaced;

– The power supply must be equipped with

protective systems.

If you encounter problems that you cannot

cope with, contact the service center.

Summary of Contents for PMIG145-C1

Page 1: ......

Page 2: ...Automatic Welding Machine 1...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16 90 10 40 MIG MAG...

Page 20: ...19 1 2 3 MIG MAG 15 2 2 4 VRD 12 24 VRD VRD MIG MAG...

Page 21: ...20 V U 6 16 GAS...

Page 22: ...21 10 NO GAS...

Page 23: ...22 off 1 2 3 4 5 6 20 30 7...

Page 25: ...24 7...

Page 26: ...25 1 2 3 4 5 6 7 U0 V X I2 A U2 V U1 I1max A I1eff A IP21S S...

Page 27: ...26 P I T P I T P I T https pittools ru servises 0 40 80...

Page 28: ...27 2 2 2 1 2 OnePower 12 I 3 4...

Page 29: ...28 3 2 2 5...

Page 34: ......