• Keep the vents of the spray gun clean at all times. If possible, prevent foreign

matter from entering the vents.

• If the body of the spray gun requires cleaning, do not use solvents but a moist

soft cloth only. Never let any liquid get inside the gun body; never immerse any

part of the spray gun into a liquid.

Note: Ozito Industries will not be responsible for any damage or injuries

caused by the repair of the sander by an unauthorised person or by mishandling

of the spray gun.

MAINTENANCE

DESCRIPTION OF SYMBOLS

CARING FOR THE ENVIRONMENT

TROUBLE SHOOTING

Power tools that are no longer usable should not be disposed of

with household waste but in an environmentally friendly way. Please

recycle where facilities exist. Check with your local council authority

for recycling advice.

Recycling packaging reduces the need for landfill and raw materials.

Reuse of recycled material decreases pollution in the environment.

Please recycle packaging where facilities exist. Check with your

local council authority for recycling advice.

Spare parts can be ordered from the Special Orders Desk

at your local Bunnings Warehouse.

For further information, or any parts not listed here, visit

www.ozito.com.au or contact Ozito Customer Service:

Australia 1800 069 486

New Zealand 0508 069 486

E-mail: [email protected]

SPARE PARTS

Problem

Cause

Remedy

Little or no material

flow

Nozzle / Suction tube clogged

Spray regulator dial to low

Suction tube loose

No pressure build up in paint pot

Air filter clogged

Clean

Increase regulator dial

Insert

Tighten paint pot

Clean or replace

Material leaking

Nozzle loose

Nozzle worn

Material build up on air cap and nozzle

Tighten

Replace

Clean

Atomization is too

coarse

Viscosity of material too high

Material volume too large

Nozzle clogged

Air filter clogged

Too little pressure build up in container

Thin material

Decrease spray regulator dial

Clean

Clean or replace

Tighten paint pot

Spray jet pulsates

Material in paint pot running out

Air filter clogged

Refill

Clean or replace

Pattern runs or sags

Applying to much material

Decrease spray regulator dial

or increase movement speed

Too much overspray

Gun too far from spray object

Too much material applied

Reduce distance

Decrease spray regulator dial

Pattern is very light

and splotchy

Moving the spray gun to fast

Decrease spray regulator dial

or decrease movement speed

V

Volts

Hz

Hertz

~

Alternating current

W

Watts

BAR

Pressure rating

Read Instruction manual

Warning

Double insulated

Wear eye, breathing,

ear protection

Do not use in raining

/min

Revolutions or r

Regulatory Compliance

Mark (RCM)

eciprocation per minute

ºC

Degrees Celsius

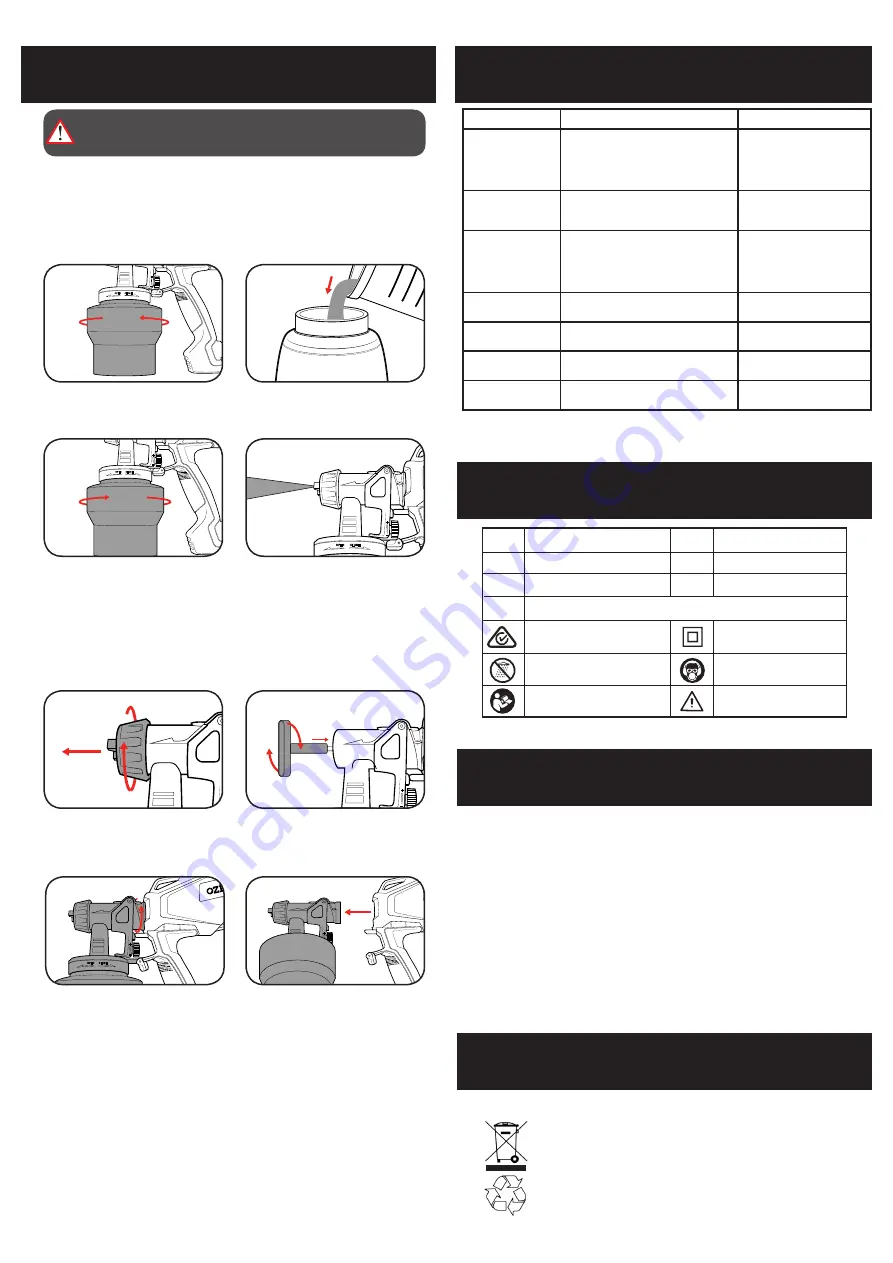

WARNING!

ENSURE THE TOOL IS DISCONNECTED FROM THE

POWER SUPPLY BEFORE PERFORMING ANY OF THE FOLLOWING

OPERATIONS.

1 Unscrew the paint pot and return

remaining material into a container.

1 Unscrew the air cap nut to remove

the air cap and nozzle.

4 Remove the paint head from the

body and dismantle the paint pot

and suction tube.

3 Unlock the locking lever and rotate

the paint head anti-clockwise until

the arrows on the neck of the paint

head and body align.

6 Take note of the holes on the air cap and nozzle, if blocked clean using the

provided cleaning needle.

3 Clean the paint pot and suction

tube with a brush and then screw

the pot back into the gun.

5 Remove the paint pot and empty

any remaining solvent.

After each use it is essential that the spray gun is cleaned thoroughly. This will

prevent any blockages occurring and provide reliable performance when you next

come to use it.

2 Fill the paint pot with solvent or

water.

Note: Use only non-

flammable liquids

2 Insert the fluid needle removal tool

over the needle. Rotate 90 degrees

and then pull firmly to remove the

needle.

5 Dip a cloth in solvent or water and clean the air cap, nozzle, rear of the paint

head and suction tube.

7 Prior to storing the spray gun, ensure it is completely dry.

4 Plug the gun back in and spray the

solvent into a container. Repeat

until clear solvent comes out.

Cleaning

Cleaning Parts

a

b