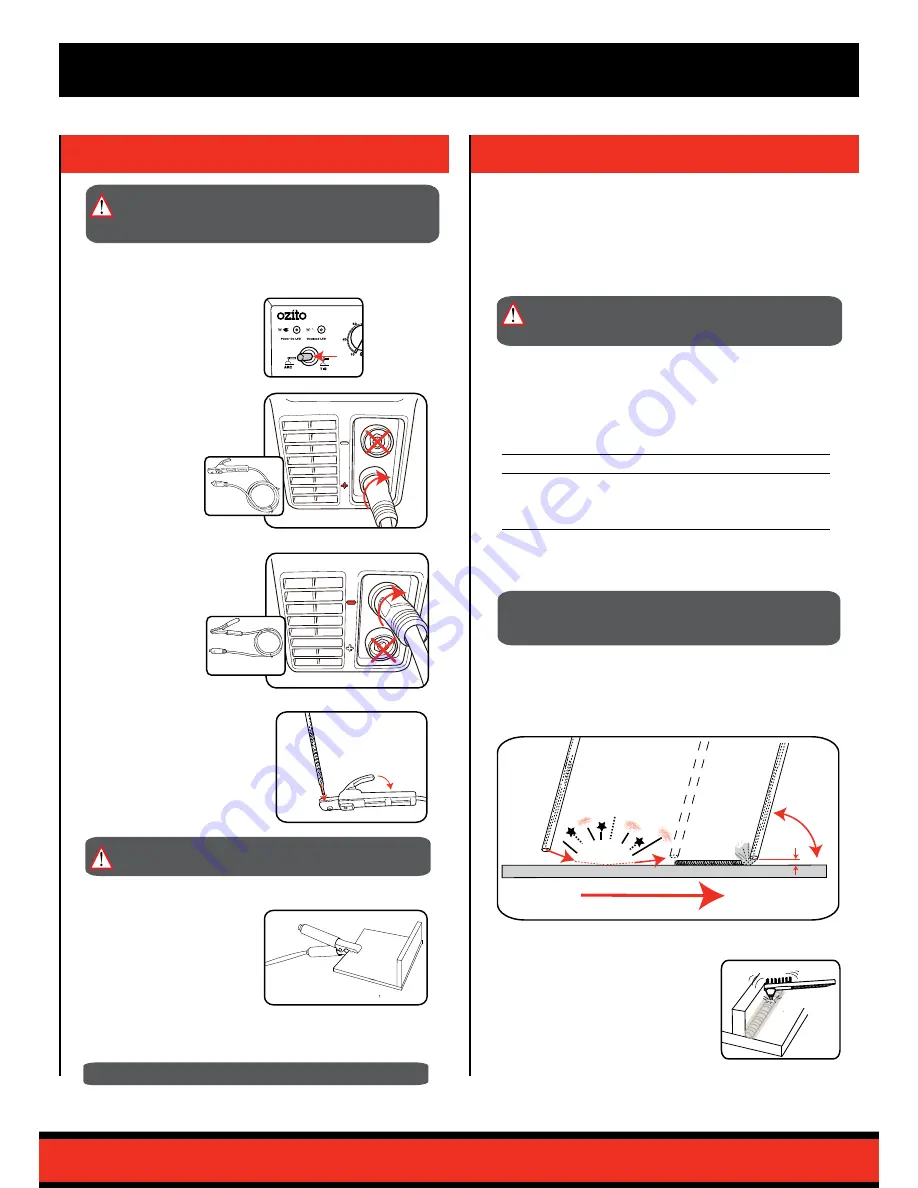

2. ARC WELDING ASSEMBLY

3. ARC WELDING

Slag

Slag is refuse left around the weld

after welding, this should only be

removed after the weld has cooled

down and is no longer glowing.

Face shield must be worn during

removal of slag.

4. Install thin (uncoated)

end of Electrode into the

arc electrode holder.

5. Attach the Earth Clamp

to the work piece

ensuring area is free

from paint or dirt so that

there is a good electrical

connection.

3. Attach Earth Clamp lead

to the NEGATIVE (-)

output terminal. Insert &

rotate until connection is

firm.

70-80º

Strike

Keep Consistant

Height

2.0mm

Welding Direction

ARC

2. Attach Arc Electrode

Holder lead to the

POSITIVE (+) output

terminal. Insert & rotate

until connection is firm.

1. Set Process Selection

Switch to ARC

WELDING process.

Preparation

Before welding ensure that:

•

You have read and understand the safety section of this

manual.

•

There is sufficient ventilation, particularly at the front and rear

of the unit.

•

You have an adequate fire-fighting devices on hand.

Electrodes & Welding Current

The welding current must be regulated in accordance with the

diameter of the electrode and the thickness of the steel being used.

This will vary with the type of electrodes and material you are using.

Below is a guide suggesting suitable currents & thickness for welding

steel.

Electrode Diameter

Welding Current (Amps)

Thickness of Steel

1.6mm

35 - 45

1.5 - 2mm

2.5mm

60 - 100

2 - 4mm

3.2mm

100 - 130

3 - 6mm

6. Connect the Inverter welder power cord into a power outlet.

Striking the Arc

Lower the electrode slowly and proceed to strike the electrode tip

against the desired join area on the work piece as if you are striking

a match. As soon as you have the arc, try to maintain a distance

from the work piece equal to the diameter of the electrode being

used, eg 2.0mm electrode, 2.0mm gap.

WARNING!:

ENSURE THE TOOL IS DISCONNECTED

FROM THE POWER SUPPLY BEFORE PERFORMING

ANY OF THE FOLLOWING OPERATIONS.

Before starting you will require a suitable Electrode according to the

specific material type and thickness.

WARNING!:

ENSURE ALL OIL, PETROL AND

FLAMMABLE CONTAINERS HAVE BEEN REMOVED

FROM WELDING AREA.

CAUTION!:

Ensure approved protective clothing and

welding helmet/mask is worn at all times to protect

your face and eyes from arc UV radiation and sparks.

WARNING!:

Do not touch the electrode while the

welder is turned on

NOTE:

Avoid use of long extension leads.