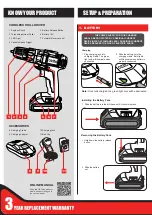

FWD

2. KEYLESS CHUCK

3. CONTROLS

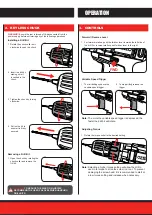

OPERATION

Forward/ Reverse Lever

Adjusting Torque

Variable Speed Trigger

1 For forward rotation, push the fwd/rev lever towards the left side of

the drill. For reverse rotation push fwd/rev lever to the right.

1 Rotate the torque collar to the desired setting.

1 To start drilling squeeze the

variable speed trigger.

2 To stop drilling release the

trigger.

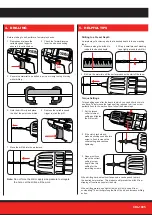

Installing a Drill Bit

Removing a Drill Bit

1 Rotate the chuck collar anti-

clockwise to open the chuck

1 Open the chuck by rotating the

chuck collar and remove the

frill bit.

3 Tighten the chuck by turning

clockwise.

2 Insert the drill bit,

making sure it

is centred in the

chuck.

4 Pull on the bit to

ensure it is firmly

secured.

Note:

The more the variable speed trigger is depressed, the

faster the drill bit will rotate.

Note:

Selecting a higher torque setting will allow the drill to

use more torque to drive the screw in or out. To prevent

damaging the screw head, it is recommended to start at

a low torque setting and increase when necessary.

CAUTION:

TO REDUCE THE RISK OF INJURY WE

RECOMMEND THE USE OF GLOVES WHEN HANDLING

DRILL BITS.

WARNING!

Ensure the tool is turned off & disconnected from the

power supply before performing any of the following operations.