CUTTERS

DEPTH GUAGE

BODY

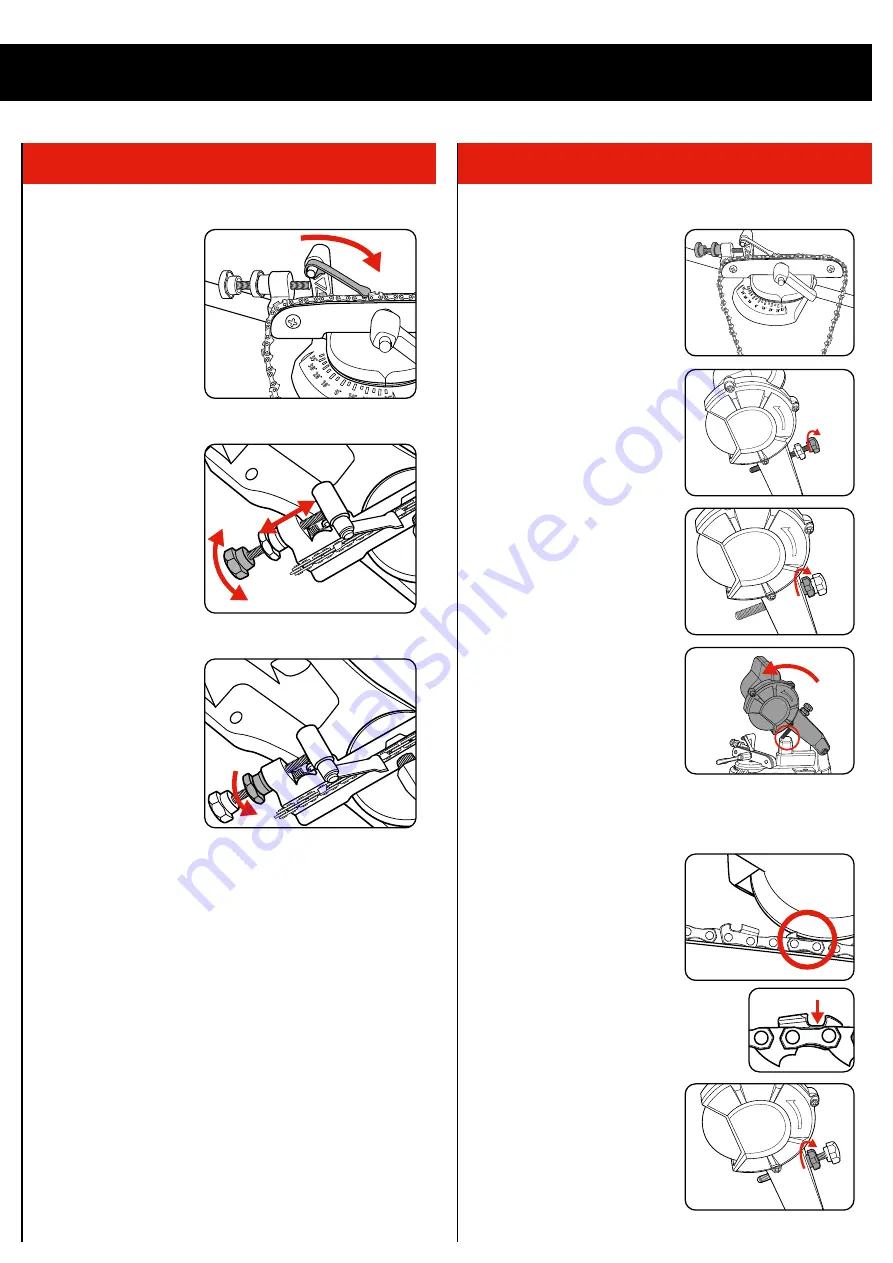

Adjusting the Chain (tooth) Stop

1. With the chain clamped in

position, rotate the chain

stop in behind the chain

tooth aligned with the

sharpening wheel from the

previous setting.

2. Adjust the chain stop knob

so that it is firmly behind

and at the bottom of the

aligned chain tooth, by

rotating either clockwise

to move the chain stop

forward or anti-clockwise

to move the chain stop

backward.

3. When the chain stop is

properly adjusted it should

be directly behind the chain

tooth as shown. To secure

in position rotate the chain

stop lock nut clockwise as

far as possible.

Adjusting the Depth of Cut

1. Ensure the chain is still locked in

place, the chain stop still flipped into

position and the chain stop knob and

lock nut are still secured.

2. Rotate the depth of grind knob

clockwise as far as it will go (so as

much of the pin is exposed under

the head piece as possible).

3. Rotate the depth of grind lock nut

towards the housing of the tool.

4. Lower wheel towards the face of the

tooth. The depth of grind pin should

meet the depth stop platform and

stop the sharpening wheel from

travelling the full distance to the

tooth.

5. Whilst still applying downward pressure on the hand piece

simultaneously start rotating the depth of grind knob anti-clockwise.

Slowly continue rotating the knob anti clockwise whilst watching the

sharpening wheel get closer to the tooth of the chain.

6. When the wheel enters along the

face of the tooth, make sure the

wheel is lowered until it covers

the full face of the tooth but

DOES

NOT

touch the tooth body below.

Alternatively, you can lower the

sharpening wheel until it firmly sits

on top of the tooth body and then

rotate the depth of grind knob 1/2

a turn clockwise to lift it slightly away from the

body. Lifting the sharpening wheel away from the

body will prevent cutting into the body or link and

damaging the chain.

7. When the depth adjustment is

correct, hold the depth of grind knob

in position with one hand, using the

free hand rotate the grind lock nut

clockwise locking the depth of grind

pin in position.

The initial set up is now complete.

Fine adjustments may still need

to be made once first sharpening

operation is performed.