ONLINE MANUAL

Scan this QR Code with

your mobile device to take

you to the online manual.

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

0

25

50

75

100

125

150

0

(1)00

(3)00

(5)00

(7)00

(9)00

2

4

6

8

10

Lb/in²

(PSI)

kPA

(BAR)

PRESSURE GAUGE

kg/cm²

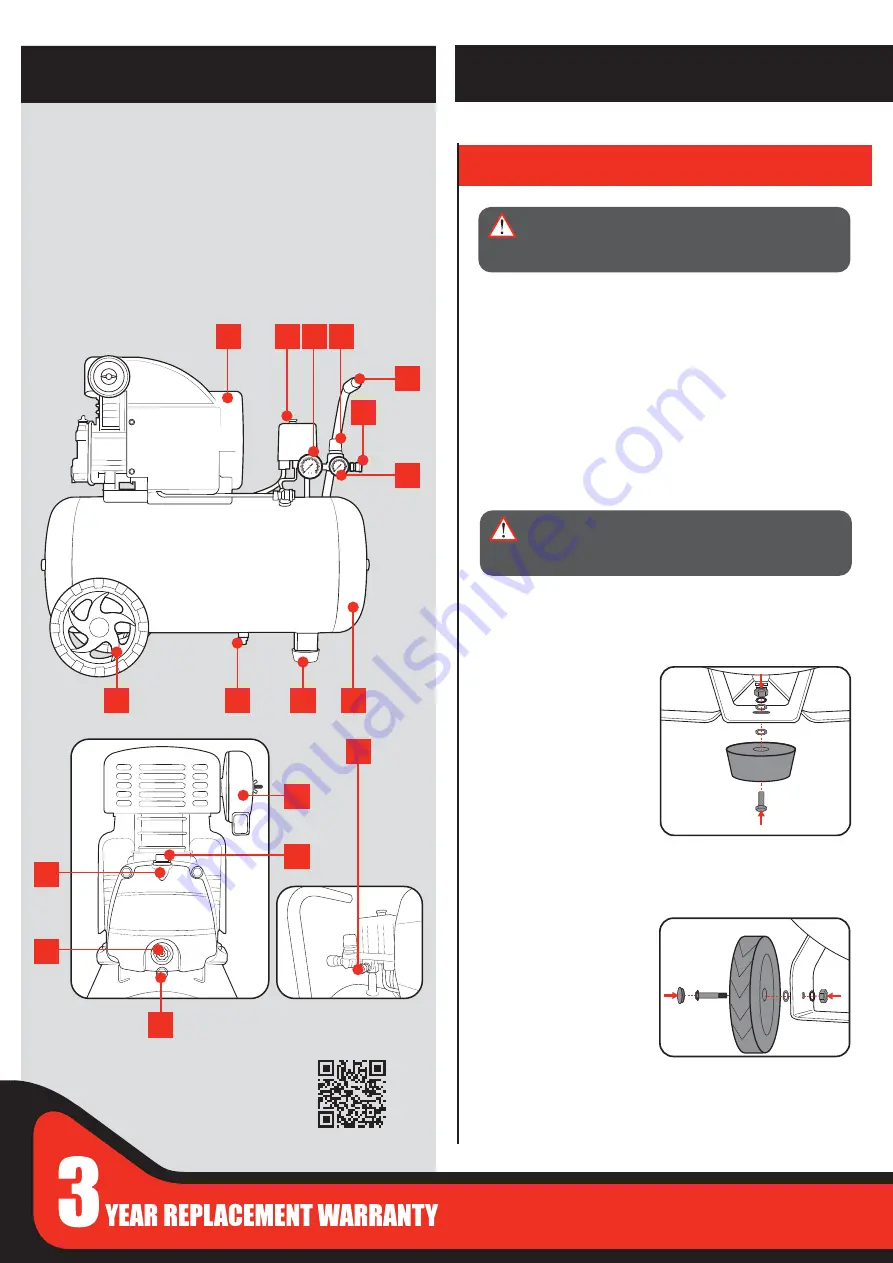

Pre-Setup Checks

• Examine the machine for signs of transit damage. If damaged, do

not use, return to place of purchase

• The compressor should be set up near to the user.

• Avoid long air lines and long supply lines (extensions).

• Make sure the intake air is dry and dust-free.

• Do not set up the compressor in damp or wet rooms. The

compressor is designed to be used in dry rooms. It is prohibited

to use the compressor in areas where work is conducted with

sprayed water.

• Before you use the machine, make sure that the mains voltage

complies with the specifications on the rating plate.

WARNING!

ALWAYS KEEP THE COMPRESSOR

UPRIGHT. TIPPING THE COMPRESSOR ON ITS SIDE

MAY CAUSE THE OIL IN THE MOTOR TO LEAK OUT

AND DAMAGE THE UNIT.

Attaching The Support Foot

1. Place the supporting foot and

then a small washer onto the

M6 bolt. Thread this through

the hole in the foot bracket.

2. Thread the other small washer

and then the spring washer

onto the bolt. Secure the

assembly with the M6 nut.

Attaching The Wheels

1. Place the M10 bolt through

the wheel and a large washer.

Then slide this through the

hole in the wheel bracket and

a large spring washer. Secure

this with a M10 nut.

2. Press the wheel cap into

place.

3. Repeat steps 1 & 2 to fit the second wheel on the opposite side of

the tank.

1. Motor Housing

2.

On/Off Button

3. Tank Pressure Gauge

4. Pressure Regulator

5. Transport Handle

6. Regulated Pressure Outlet

7. Regulated Pressure Gauge

8. Pressure Tank

9. Support Foot

10. Drain Valve

11. Wheels

12. Safety Relief Valve

13. Intake Air Filter

14. Oil Sealing Plug

15. Oil Drainage Screw

16. Oil Level Window

17. Oil Filler Opening

AIR COMPRESSOR

KNOW YOUR PRODUCT

1. ASSEMBLY

SETUP & PREPARATION

WARNING!

ENSURE THE TOOL IS TURNED OFF

AND DISCONNECTED FROM THE POWER SUPPLY

BEFORE PERFORMING ANY OF THE FOLLOWING

OPERATIONS.

1

4

13

14

17

16

2

12

6

3

15

8

10

9

5

7

11