3.6 Primary

F

low

and

R

eturn and

M

otorised valve

3.6.1

The

Heat Pump

primary flow and return connections should be made connections 1 & 2. The motorized valve

can be connected to either the primary flow or return pipe. The primary flow and return fittings are 3/4’’ BSP female.

The valve has 22mm x copper connections. The direction of primary flow in the coil is bottom to top. The maximum

operating temperature of the primary flow would typically be 82°C.

3.6.2

For electrical connection of the motorised valve and immersion heater, please read Electrical

Installation Instructions. (Pages

5

).

4

.

Commissioning

and

f

illing up

4

.1

Commissionin

g

4

.1.1

Check all connections for tightness.

4

.1.2

Open hot water tap furthest away from the OSO water heater. Open the mains stop cock to fill the water heater.

When water flows evenly from tap, allow to run for a few minutes to flush through any dirt, swarf or residue, then close

the tap. Open successive hot taps to purge any remaining air.

4

.1.3

Check all water connections for leaks and rectify if necessary.

Manually operate Expansion relief valve

4

(see page

3

) to ensure free water flow through discharge pipe by turning

knob counter-clockwise. To close continue to turn counter-clockwise until the valve shuts.

Manually operate Temperature and Pressure Relief Valve

5

(see page

3

) to ensure free water flow through discharge

pipe (Turn knob counter-clockwise).

Switch electrical power on.

5

.Draining & flushing out the system.

5

.1

Draining

Switch off the electrical power (Important to avoid damage to element). Isolate

Heat Pump

from

OSO unit. Turn off the cold water supply valve. Open hot water tap. Open drain

12

(see page 3)

at base of cylinder .

The unit will drain. Draining process may be speeded up by opening the temperature and pressure relief valve. An

internal ø18 mm hose can be applied to lead the water to a gully, sink or similar

.

5.2

System

f

lushing

This

will not be necessary under normal circumstances as the line strainer will

prevent ingress of foreign materials, however if flushing is required, run at least 50 litres of

water from the cylinder at the highest possible flow rate. Close the taps and follow draining

procedure (above).

6.

Electrical installation

- all wiring must conform to current IEE regulations

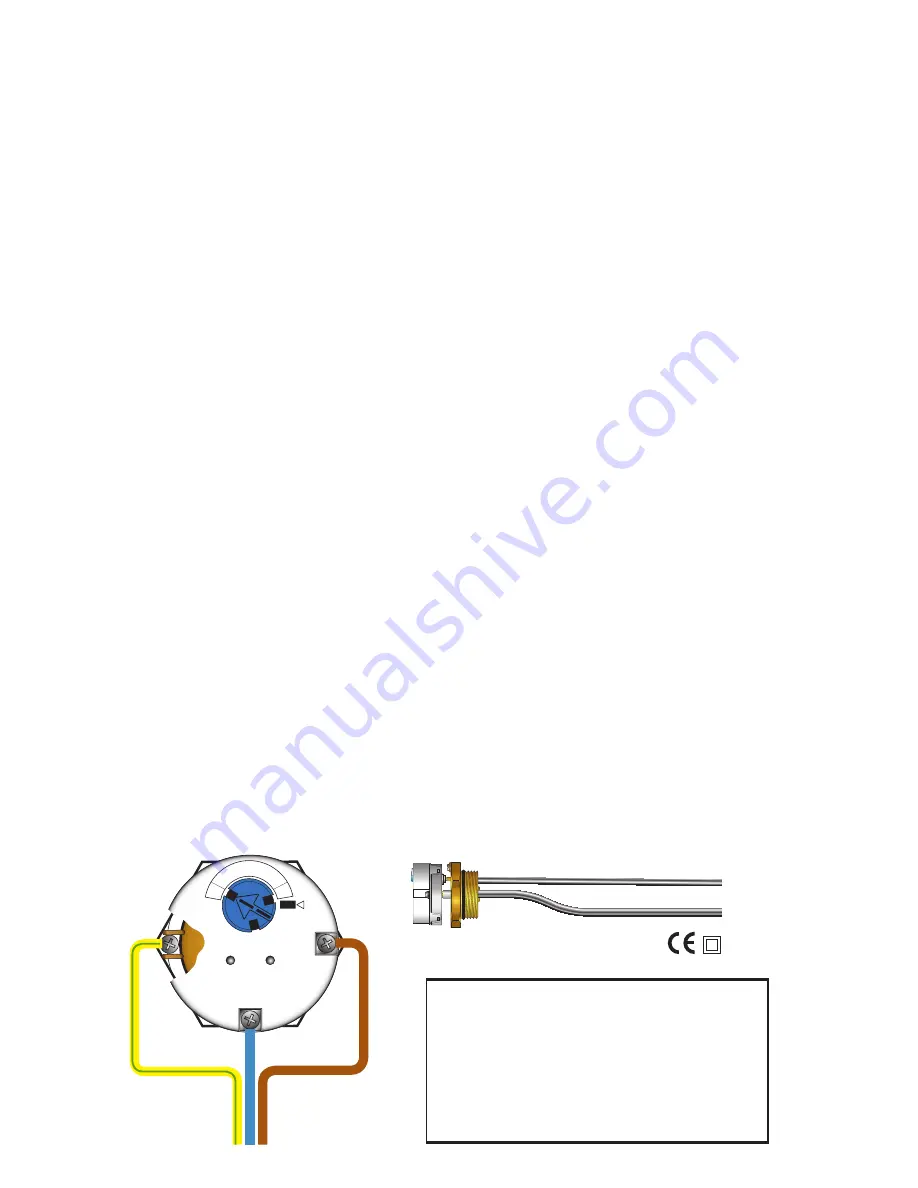

6.1

I

mmersion

H

eater

Thermostat

The immersion heater is designed as an auxiliary heater as an emergency back-up. Power to immersion heaters

should not be switched on until the unit is filled with water. All units are fitted with one 3 kW immersion heater which is

located behind the electrical box. Alternative thermostats should not be used, regulations require

immersion

heaters on

unvented cylinders to be connected with a thermal cut-out.

Follow the wiring instructions below connecting the live,

neutral and earth as indicated. The unit must be permanently connected to the electrical supply through a double-pole

linked switch with a minimum break capacity of 13 amps. All internal wiring is factory mounted. Each immersion heater

has a working thermostat adjustable between

18

°C - 70°C

(+/- 5°C)

. A safety cut-out is also incorporated within the

thermostat and will operate at 8

7

°C

(

±

7

°C

)

. Should this happen, check reasons for thermal cut-out button being

released and when

satisfied

press the reset button

.

5

2 KW

OS

O

3

2

4

5

a

t

e

nt

e d

A

T

1

1 5

16

A

2

5

0

V

B

Safety reset

Eart

h

Liv

e

Neutra

l

earth cable

connected to

immersion

Thermostat

sensor pocket

Immersion

IP21

OSO Hotwater (UK) Limited can not be

held responsible if alternative wiring plans

are used.

Important: Before resetting the safety cut-

out or altering the thermostat setting isolate

electrical supply to the unit before removal

of the lid.

Ensure the lid to the electrical box

is replaced.

Summary of Contents for DGC 200

Page 11: ......