SECTION 5 - HYDRAULICS

3121827

– JLG Lift –

5-19

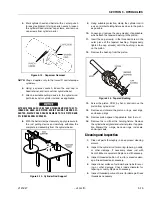

19.

Continue pushing the rod into the barrel until the cyl-

inder head gland can be inserted into the barrel cyl-

inder.

20.

Secure the cylinder head gland using the washer

ring and socket head bolts.

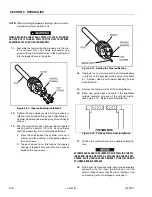

21.

After the cylinder has been reassembled, the rod

should be pushed all the way in (fully retracted) prior

to the reinstallation of any holding valve or valves.

22.

If applicable, install the cartridge-type holding valve

and fittings in the rod port block, using new o-rings

as applicable. (See Table 5-3, Holding Valve Torque

Specifications).

IF THE CYLINDER IS TO BE TESTED PRIOR TO INSTALLATION ON

THE MACHINE, EXTREME CARE SHOULD BE USED TO INSURE

THAT THE OUTER END OF THE ROD IS SUPPORTED. USE EITHER

A TRAVELING OVERHEAD HOIST, FORK-LIFT, OR OTHER MEANS

TO SUPPORT THE OVERHANGING WEIGHT OF THE EXTENDING

ROD.

Table 5-1.Cylinder Head and Tapered Bushing Torque

Specifications

Description

Head Torque Value

(Wet)

Tapered Bushing

Torque Value (Wet)

Jib. Cylinder

41 Nm

(30 ft. lbs.)

7 Nm

(5 ft. lbs.)

Level Cylinder

41 Nm

(30 ft. lbs.)

7 Nm

(5 ft. lbs.)

Master Cylinder

41 Nm

(30 ft. lbs.)

7 Nm

(5 ft. lbs.)

Master Cylinder

E/M400A,E/M450A,

108 Nm

(80 ft. lbs.)

N/A

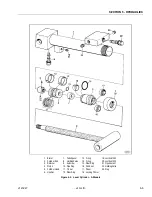

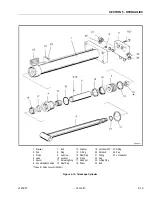

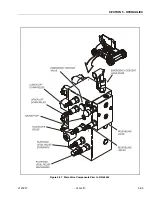

Figure 5-23. Rod Assembly Installation

Table 5-2. Cylinder Piston Nut Torque Specifications)

Description

Nut Torque

Valve (Wet)

Setscrew

Torque Value

(Dry)

Upper

Lift Cylinder

200 ft. lbs.

(270Nm)

100 in. lbs.

(11 Nm)

Mid

Lift Cylinder

400 ft. lbs.

(542 Nm)

100 in. lbs.

(11 Nm)

Mid

Lift Cylinder

E400An

200 ft.lbs.

(270 Nm)

100 in. lbs

11 (Nm)

Lower

Lift Cylinder

400 ft. lbs.

(542 Nm)

100 in. lbs.

(11 Nm)

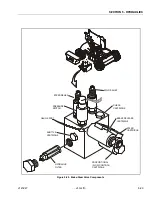

Table 5-3. Holding Valve Torque Specifications

Description

Torque Value

SUN - 7/8 HEX M20 X 1.5 THDS.

30-35 ft. lbs.

(41-48 Nm)

SUN - 1 1/8 HEX 1 -14 UNS THDS.

45-50 ft. lbs.

(61-68 Nm)

SUN - 1 1/4 HEX M36 X 2 THDS.

150-160 ft. lbs.

(204-217 Nm)

RACINE - 1 1/8 HEX 1 1/16 - 12 THDS.

50-55 ft. lbs.

(68-75 Nm)

RACINE - 1 3/8 HEX 1 3/16 - 12 THDS.

75-80 ft. lbs.

(102-109 Nm)

RACINE - 1 7/8 HEX 1 5/8 - 12 THDS.

100-110 ft. lbs.

(136-149 Nm)

Summary of Contents for JLG E400AJP

Page 2: ......

Page 32: ...SECTION 1 SPECIFICATIONS 1 18 JLG Lift 3121827 NOTES...

Page 42: ...SECTION 2 GENERAL 2 10 JLG Lift 3121827 NOTES...

Page 54: ...SECTION 3 CHASSIS TURNTABLE 3 12 JLG Lift 3121827 Figure 3 3 Speed Sensor Orientation...

Page 60: ...SECTION 3 CHASSIS TURNTABLE 3 18 JLG Lift 3121827 Figure 3 7 Steering Components and Spindles...

Page 62: ...SECTION 3 CHASSIS TURNTABLE 3 20 JLG Lift 3121827 Figure 3 9 Tilt Sensor Location...

Page 86: ...SECTION 3 CHASSIS TURNTABLE 3 44 JLG Lift 3121827 Figure 3 16 Swing Components...

Page 88: ...SECTION 3 CHASSIS TURNTABLE 3 46 JLG Lift 3121827 Figure 3 18 Battery Cable Connections...

Page 90: ...SECTION 3 CHASSIS TURNTABLE 3 48 JLG Lift 3121827 Figure 3 20 On Board Generator...

Page 97: ...SECTION 3 CHASSIS TURNTABLE 3121827 JLG Lift 3 55 Figure 3 22 Generator Components...

Page 116: ...SECTION 3 CHASSIS TURNTABLE 3 74 JLG Lift 3121827 NOTES...

Page 127: ...SECTION 4 BOOM PLATFORM 3121827 JLG Lift 4 11 Figure 4 10 Boom Limit Switches...

Page 140: ...SECTION 4 BOOM PLATFORM 4 24 JLG Lift 3121827 Figure 4 13 Rotator Counterbalance Valve...

Page 178: ...SECTION 5 HYDRAULICS 5 24 JLG Lift 3121827 Figure 5 26 HydraForce Cartridge Torque Value Chart...

Page 214: ...SECTION 6 JLG CONTROL SYSTEM 6 34 JLG Lift 3121827 NOTES...

Page 257: ......