Installation Instructions for VAPRO Rupture Disks in VRDI

Holder

P.O. Box 1327 / 1701 W. Tacoma/ Broken Arrow, OK 74012

Telephone: (918) 258-5626 Fax: (918) 251-2809

“Quality Products to meet Industry Needs”

PS 11.12

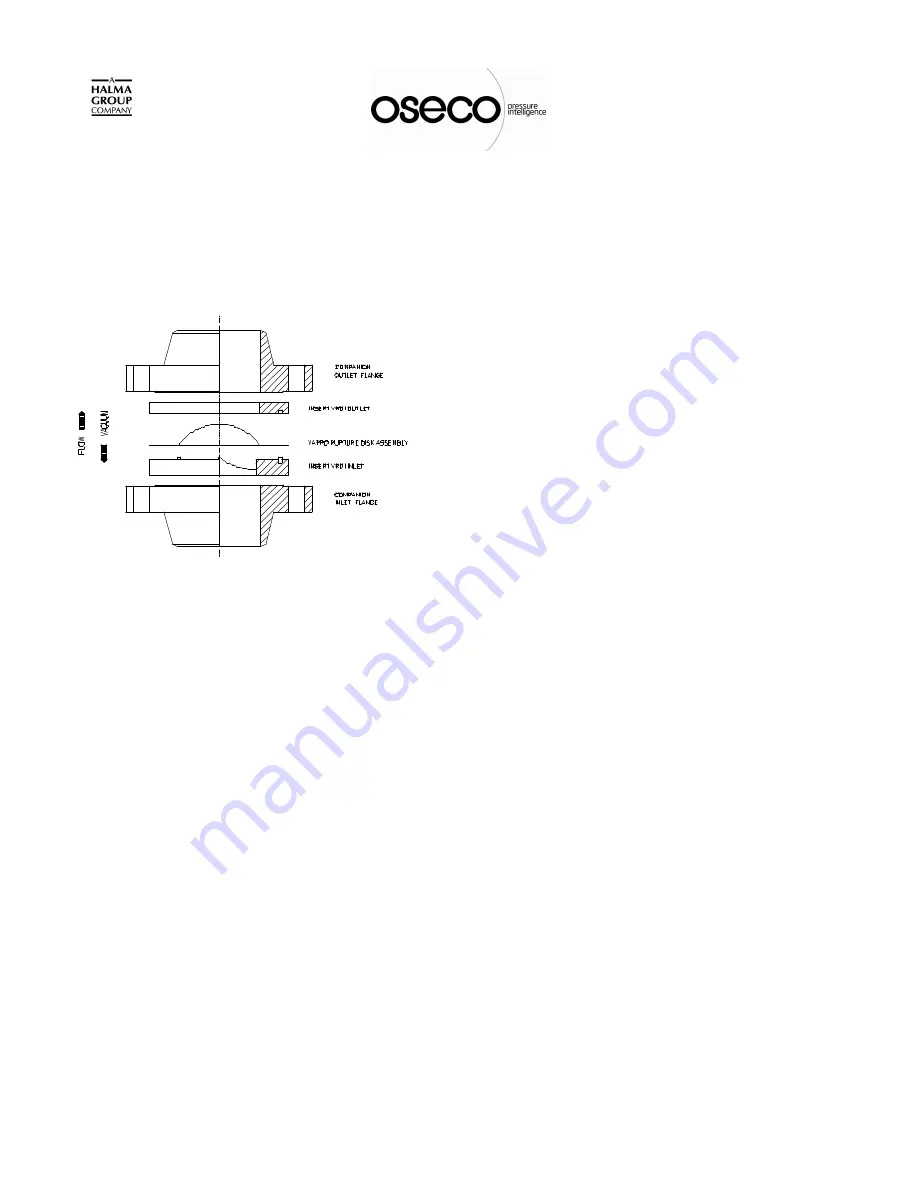

TYPICAL VRDI INSTALLATION

CAUTION

All rupture disk installations should be located to

allow full unrestricted discharge of a burst disk when

over pressure of the system occurs. Never locate a

rupture disk assembly where the discharge from a

burst disk can directly impact personnel or equipment.

Venting of a burst disk discharge must always be

routed to a safe disposal area. Handle burst rupture

disks carefully! Avoid their sharp, jagged edges when

removing same from holder. The knife blades in the

VRDI holder are extremely sharp. Handle holders

very carefully to avoid injury.

IMPORTANT

The VAPRO rupture disk assembly is a dual acting

precision piece of equipment. Handle it with

extreme care. Avoid scratching, bending, denting

or damaging the dome and/or flat seat areas of the

metal disk membrane. Handle the disk by the flat

outer annular seating surfaces and avoid the dome

area as much as possible. Never carry a VAPRO

disk/holder assembly by the name tag alone as

damage to the disk could occur. Do not place tools

or foreign objects on top of the knife blades or

holder. The knife blades must be kept very sharp

and free of nicks and defects in order for the disk

assembly to function properly.

RUPTURE DISK HOLDER PREPARATION

1) Loosen and remove flange bolting only after

verifying that the system is de-pressurized. Always

purge toxic and/or dangerous materials area from

any system that is to be opened to a safe disposal.

.

2) Slip the holder insert from between the

companion piping flanges and place on a flat work

surface. Verify that all holder restraints have been

removed. Separate the holder inlet from the outlet

and remove the existing rupture disk assembly.

3) Thoroughly inspect and clean all seating

surfaces of the disk holder. Do

not

scrape or

scratch any seating surface including the raised

nubbin area! If wiping these surfaces with a clean

cloth and a suitable solvent does not remove

surface residues, fine emery cloth or steel wool may

be utilized. Care should be exercised

not

to exert

sufficient pressure on the emery cloth or steel wool

to "cut or groove" these surfaces. When in doubt

about the proper condition of these sealing

surfaces, contact OSECO for further instructions.

4) Inspect knife blade points and edges. Knife blade

edges must be razor sharp and free of nicks or

defects. Points must be sharp and undamaged for

the disk assembly to function properly. Contact

OSECO for repair or replacement of dull or

damaged knife blades.

Do not install the Assembly if the blades are

dull, nicked or Damaged.