MAINTENANCE AND INSPECTION

Read the section title SAFETY.

SERVICE AND REPAIRES

All quality tools will eventually require servicing or replacement of parts due to wear from

normal use. It is recommended that these operations should be performed by a professional

technician.

NOTE:

The information contained in this Manual is designed to assist you in the safe

maintenance of the nailer. Some illustrations in this Manual may show details or attachments

that are different from those on your nailer.

WARNING: Disconnect air hose and remove nails from nailer when:

Doing maintenance and inspection

Cleaning a jam

Inspecting the magazine

1. DISCONNECT AIR HOSE.

2. Clean the magazine. Remove dust which may have accumulated in the magazine.

3. Lubricate the nailer rail with nailer lubricant.

Clearing a jam

Remove a jammed nail in the following order:

1. DISCONNECT AIR HOSE.

2. Remove all nails.

3. Remove the jammed nail with a slotted head screwdriver.

4. In case of frequent jams, contact an authorized service center.

A qualified person should perform repair and maintenance

Periodic maintenance to be performed:

Check that the piston bumper is operating normally. A damaged piston bumper may

cause damages to other component parts.

Check o-rings for wear or damage. Damaged o-rings may affect overall performance.

Make sure all screws are secure. Loose screws may affect overall performance.

When repairing a tool, make sure the internal parts are clean and lubricated.

Storing

When not in use of an extended period, apply a thin coat of the lubricant to the steel

parts to avoid rust.

The nailer should be stored in a warm and dry place when not in use. Do not store the

nailer in a cold weather environment.

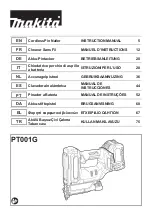

Summary of Contents for CN80F

Page 13: ...TOOL SCHEMATIC CN80F...