Fit the

Spindle

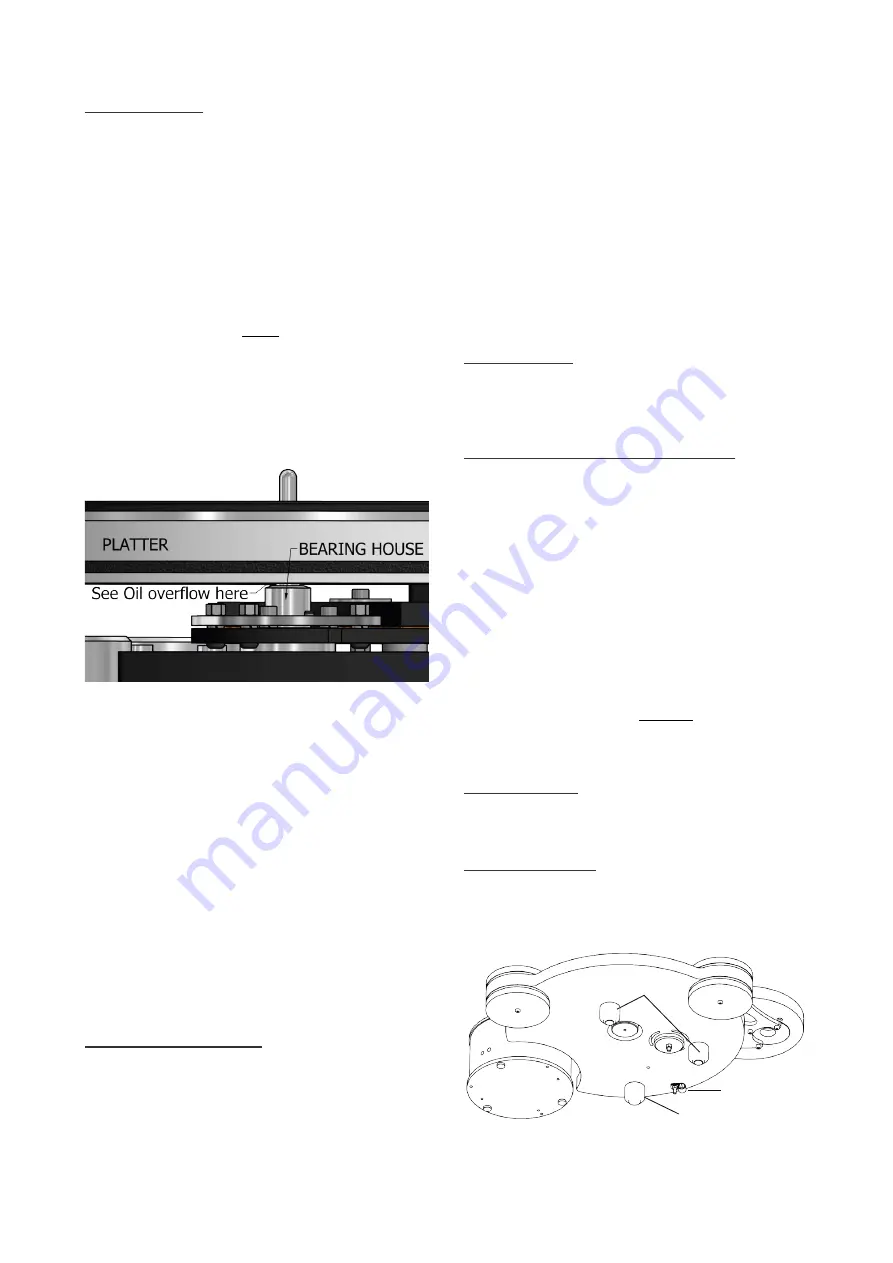

Oil the bearing

Run approximately 17 drops of the oil supplied into the

top of the bearing house. The spindle will appear a loose

fit in the bearing house until the oil is added. Do not use

anything other than Origin Live oil for performance

reasons.

Insert the spindle

Inserting the spindle into the bearing house needs

attention as careless handling can damage the bearing

surfaces. Wipe the spindle surface first to ensure that it's

absolutely clean and very gently insert it into the bearing

house. If the oil does not overflow when the spindle

touches the bottom then try 2 more drops repeatedly till

you achieve overflow. Overflow can only be seen by

looking at the top of the bearing house with the spindle

inserted. You should notice an oil ridge around the

spindle – see diagram below.

Wipe away excessive overflow at the top of the bearing

house but be careful to leave oil clinging to the spindle

as you need the top of the bearing to be lubricated by oil

overflow and things like tissue paper can suck this area

dry by capillary action. You should spin the spindle

slowly after it has settled into the bearing to ensure even

distribution of oil.

Note that when you oil the bearing, you can get a false

impression of overflow if the spindle has oil on it - the

oil simply scrapes off as the bearing slides in and ends

up on the top of the bearing house. You can “feel”

overflow when you insert the spindle and it meets

resistance at the bottom. This is not a “thud” of the

spindle hitting the bottom but rather a build up of

pressure as the bearing lands on a bed of oil. By further

pressing, you can then see the oil being squeezed out at

the top.

Notes on the bearing:

The bearing has significant play “rock” which runs

counter to expectations. However, this feature achieves

very low friction levels. The spindle effectively rotates

on a thick film of oil without contacting the bearing

sides.

This means there is almost imperceptible platter

movement in rotation. Small low frequency deviations of

this nature are insignificant to performance and far

outweighed by the advantages of low friction and

reduced vibration.

All platters are rigorously checked for level spinning up

to 45rpm - if you notice significant platter flutter once

the belt is fitted, then remove the platter and clean taper

surfaces. Refit it till it sits true.

Do not spin the platter faster than 45rpm as the bearing

relies on a high precision oil film designed for optimal

sound quality within a specific speed range. At higher

than normal running speeds there will be slight platter

flutter.

Fit the Platter

Fit the platter gently over to the spindle but ensure the

tapered mating surfaces are absolutely clean before

assembly by wiping with tissue paper.

For Multi-Layer platter if included

Holding the Multi-layer platter

The top thin layers of the multi-layer platter are fragile

so do not hold the weight of the platter using the top

layers – also avoid placing the platter upside down on

surfaces as the spindle is fastened to a relatively fragile

material.

Slacken screws in the Multilayer

P

latter by 2/3rds

of a turn

The screws are tightened for transit to keep all layers

concentric with one another. However once you have

mounted the multi-layer platter, slacken all the white

nylon screws in the top of the platter anti-clockwise by

2/3 rds of a turn. This step is

essential

to allow the multi-

layer platter to perform as intended and makes a big

difference.

Fit Platter Mat

Finally add the platter mat ensuring the printed logo is

uppermost for sound quality reasons.

Adjust deck feet

No foot should be tightened fully onto the plinth as

performance is best when the foot sits on the thread

alone.

REAR METAL THREADED

FOOT

PLASTIC THREADED FEET

CABLE CLIP