7

z

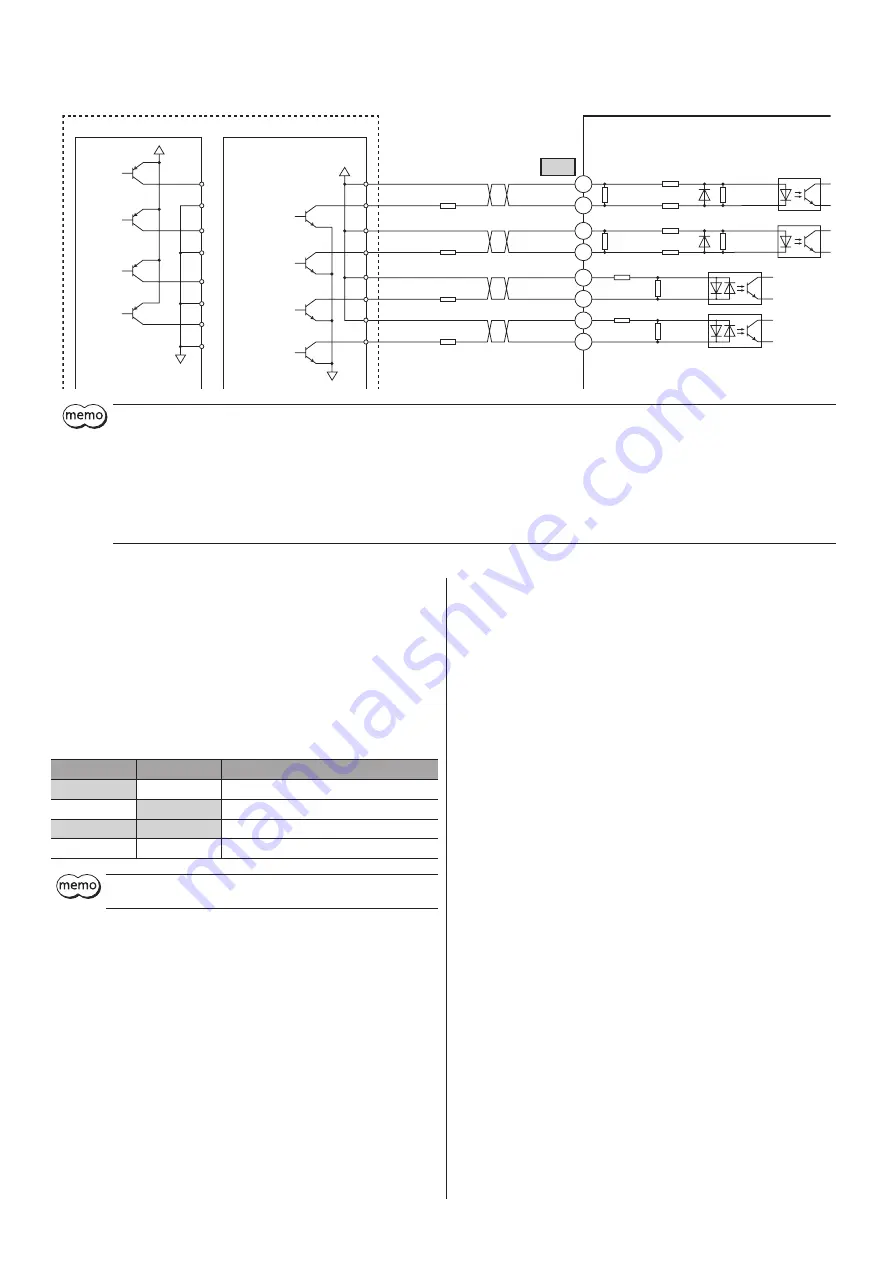

When using the voltage of input signals at 24 VDC

Driver

R1

1.5 to 2.2 kΩ, 0.5 W or more

R1

1.5 to 2.2 kΩ, 0.5 W or more

R2

1.5 to 2.2 kΩ, 0.5 W or more

0 V

0 V

FWD

RVS

AWO

CN3

Twisted pair cable

4

3

2

1

6

5

100 Ω

Current sink output circuit

Current source output circuit

Programmable controller

100 Ω

100 Ω

100 Ω

470 Ω

2.2 kΩ

2.2 kΩ

2.2 kΩ

2.2 kΩ

1 kΩ

M0

8

7

470 Ω

1 kΩ

24 VDC

24 VDC

R2

1.5 to 2.2 kΩ, 0.5 W or more

y

The input voltage specification for the FWD input and RVS input is 5 VDC. If the voltage exceeding 5 VDC is applied, connect an external resistor R1 so

that the input current becomes 7 to 20 mA.

Example) When the 24 VDC is connected: R1=1.5 to 2.2 kΩ, 0.5 W or more

y

The input voltage specification for the AWO input and M0 input is 5 VDC. If the voltage exceeding 5 VDC is applied, connect an external resistor R2 so

that the input current becomes 5 to 15 mA.

Example) When the 24 VDC is connected: R2=1.5 to 2.2 kΩ, 0.5 W or more

y

When an accessory external resistor module

VCS01

is connected instead of the external resistor R1 and R2, use at 24 VDC ±5%.

y

Up to three cables can be used for the connection between the motor and driver. Keep 10 m (32.8 ft.) or less for the wiring distance between the motor

and driver.

Explanation of I/O signals

z

Input signals

All input signals of the driver are photocoupler inputs.

The signal input state represents "ON: Carrying current" or "OFF: Not carrying

current" state of the internal photocoupler rather than the voltage level of the

signal.

•

FWD (Forward) input, RVS (Reverse) input

Turning the FWD input or RVS input ON will start continuous operation.

FWD input

RVS input

Motor movement

ON

OFF

The motor rotates in the forward direction.

OFF

ON

The motor rotates in the reverse direction.

ON

ON

Immediate stop

OFF

OFF

Deceleration stop

If the driver power is turned ON while the FWD input or RVS input is

being ON, the motor will operate.

•

AWO (All windings off) input

When the AWO input is turned ON, the motor current will be cut off and the

motor will lose its holding torque. The motor output shaft can be turned

manually.

When the AWO input is turned OFF, current will be supplied and the holding

torque will be restored.

Also, when the overheat alarm was generated, the alarm can be reset if the

AWO input is turned from OFF to ON after the circuit temperature of the

driver decreased 75 °C (167 °F) or lower.

•

M0 (Data selection) input

Turning the M0 input OFF will select the Speed1 (high speed).

Turning the M0 input ON will select the Speed2 (low speed).

z

Output signals

The driver outputs signals are photocoupler/open-collector output.

The signal output state represents "ON: Carrying current" or "OFF: Not

carrying current" state of the internal photocoupler rather than the voltage

level of the signal.

•

ALM (Alarm) output

The ALM output is normally closed. When an alarm generates, the ALM output

will turn OFF and the motor current will be cut off. At the same time, the PWR/

ALM LED of the driver will blink in red.

•

PLS-OUT (Pulse) output

The PLS-OUT output are output 50 times with each revolution of the motor

output shaft. ON-OFF ratio (duty ratio) for when the motor is operated at

constant speed is 50%.

The maximum output frequency is 500 Hz.