4

●

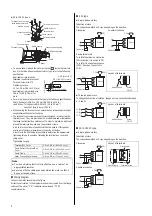

25 to 150 W types

Terminal cover screws

(with rubber seal and

metal washer)

Terminal box cover

Cable outlet of

terminal box

Motor connecting

terminal

Cable clamp

Terminal plinth

Gasket

Gasket

Terminal block

Pressure sealing ring

Rubber packing

Cable

Terminal cover

Cable clamp

•

To ensure safety, ground the motor using the

inside the terminal

box. On the three phase round shaft motor type, refer to the following

specification.

Applicable crimp terminal:

Insulated round crimp terminal

Terminal screw size: M4

Tightening torque:

1.0 to 1.3 N·m (8.8 to 11.5 lb-in)

Applicable minimum lead wire

size: AWG18 (0.75 mm

2

) or

more

Ø4.1 (Ø0.161) or more

4.5 (0.177) or less

9 (0.354) or less

Unit [mm (in.)]

•

For wiring, be sure to use cable that meets the following specifications.

Cable: Diameter is Ø6.0 to 12.0 mm (Ø0.236 to 0.472 in.)

Lead Wires: Thickness is AWG24 to 12 (0.2 to 3.5 mm

2

)

Length of strip is 8 mm (0.31 in.)

•

When sealing the terminal cover, ensure that no scraps or particles get

caught between the contact surfaces.

•

The terminal cover screws are specifically designed for mounting the

terminal cover. They are provided with a rubber seal and metal washer

that keep the terminal box splashproof. In order to maintain a tight seal

around the terminal box, use only the provided screws.

Also, this terminal box is constructed to hold a gasket. If this gasket

comes out of the box, please reseal it correctly on the box.

Also refer to the tightening torque table to determine the appropriate

tightening torque to use when fastening the terminal box cover and

cable outlet.

Tightening torque

Terminal Box Cover

0.

3

to 0.

4

N·m (

42

to

56

oz-in.)

Cable Outlet of Terminal Box

Cover

2.5 to 3.8 N·m (350 to 530 oz-in.)

Cable Clamp

0.2 to 0.3 N·m (28 to 42 oz-in.)

Motor Connecting Terminals

0.5 to 0.8 N·m (71 to 113 oz-in.)

Note

To make shielding function fully effective, use a cable of an

appropriate diameter.

Securely affix the cable exposed outside the motor so that it

does not receive stress.

Wiring diagram

Connect the motor according to the figure.

Directions of rotation in the diagram are shown as viewed from the flange

surface of the motor. “CW” indicates clockwise and “CCW”

counterclockwise.

6 W type

●

Single-phase motors

Induction motors

The connection method will vary, depending on the direction.

Clockwise Counterclockwise

CW

Capacitor

L

N

Motor

U1

U2

Z2

Capacitor

CCW

L

N

Motor

U1

U2

Z2

Reversible motors

To rotate the motor in a clockwise

(CW) direction, flip switch to CW.

To rotate it in a counterclockwise

(CCW) direction, flip switch to

CCW.

Layout of terminals

CW

Capacitor

CW

CCW

CCW

N

Motor

U1

U2

Z2

L

Rubber bush

Screw

3-M3.5

U1

U2

Z2

●

Three-phase motors

To change the direction of rotation, change any two connections between

U, V and W.

Layout of terminals

U

V

W

CW

Motor

L1 (R)

L2 (S)

L3 (T)

Rubber bush

Screw

3-M3.5

W

V

U

25 to 150 W type

●

Single-phase motors

Induction motors

The connection method will vary, depending on the direction.

Clockwise

Layout of terminals

CW

Capacitor

L

N

Motor

U1

U2

Z2

PE

Cable clamp

4 terminals

Terminal block

Z2

U2

U1

Counterclockwise

Capacitor

CCW

L

N

Motor

U1

U2

Z2

PE