2

Model

Motor model

Capacitor model

Combination type

Pinion shaft type

5RK60AW-

J

5RK60GVH-AWJ

5RK60GVH-AW

CH250CFAUL2

5RK60AW-

U

5RK60GVH-AWU

CH200CFAUL2

5RK60CW-

J

5RK60GVH-CWJ

5RK60GVH-CW

CH60BFAUL

5RK60CW-

E

5RK60GVH-CWE

CH50BFAUL

5RK90AW-

J

5RK90GVR-AWJ

5RK90GVR-AW

CH350CFAUL2

5RK90AW-

U

5RK90GVR-AWU

CH300CFAUL2

5RK90CW-

J

5RK90GVR-CWJ

5RK90GVR-CW

CH80BFAUL

5RK90CW2-

E

5RK90GVR-CW2E

5RK90GVR-CW2 CH70BFAUL

Installation

Location for installation

Install it in a well-ventilated location that provides easy access for inspection.

The location must also satisfy the following conditions:

z

•

Inside an enclosure that is installed indoors (provide vent holes)

z

•

Operating ambient temperature

−10 to +40 °C (+14 to +104 °F) (non-freezing)

−10 to +50 °C (+14 to +122 °F) for 100 V/200 V

z

•

Operating ambient humidity 85%, maximum (non-condensing)

z

•

Area that is free from an explosive atmosphere or toxic gas (such as sulfuric

gas) or liquid

z

•

Area not exposed to direct sun

z

•

Area free of excessive amount dust, iron particles or the like

z

•

Area not subject to splashing water (storms, water droplets), oil (oil droplets) or

other liquids

z

•

Area free of excessive salt

z

•

Area not subject to continuous vibration or excessive shocks

z

•

Area free of excessive electromagnetic noise (from welders, power machinery,

etc.)

z

•

Area free of radioactive materials, magnetic fields or vacuum

z

•

1000 m (3300 ft.) or less above sea level

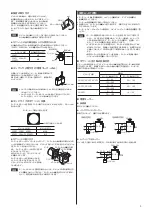

How to install the motor

For the pinion shaft type, assemble the motor and gearhead (sold separately).

Refer to "Installing the gearhead" on 3 page about how to assemble the motor

and gearhead.

z

z

Installation to equipment

Drill holes on the mounting plate and fix the motor and gearhead on the plate

using four screws (provided).

For pinion shaft type, the mounting screws are provided with the gearhead.

Motor

Screw provided

with gearhead

Gearhead

Mounting plate

Washer

Nut

Spring Washer

Maximum thickness of mounting plate for the case of using provided screws is

as below chart.

Gearhead model

∗

Nominal

diameter of

screw

Tightening

torque

[N·m (lb-in)]

Maximum thickness

of mounting plate t

[mm (in.)]

2GV

M4

1.8 (15.9)

5 (0.20)

3GV

,

4GV

M6

6.4 (56)

8 (0.31)

5GV

,

5GVH

,

5GVR

M8

15.5 (137)

12 (0.47)

z

∗

The square box in the gearhead model will contain a value representing the

gear ratio.

z

z

Motor with cooling fan

When installing a motor with cooling fan onto a device, leave 10 mm (0.39 in.) or

more behind the fan cover or open a ventilation hole so that the cooling inlet on

the back of the motor cover is not blocked.

z

•

Dispose the product correctly in accordance with laws and regulations, or

instructions of local governments.

Preparation

Checking the product

Verify that the items listed below are included. Report any missing or damaged

items to the branch or sales office from which you purchased the product.

z

•

Motor ......................................1 unit

(The combination type comes with the motor and its dedicated gearhead pre-

assembled.)

z

•

Capacitor ................................1 piece (only for single-phase motors)

z

•

Capacitor cap .........................1 piece (only for single-phase motors)

z

•

OPERATING MANUAL ...........1 copy

z

•

Set of mounting screws ..........1 set (only for combination type)

(Mounting screws, hexagonal nuts, washers, spring washers 4 pieces each,

parallel key 1 piece)

Checking the model name

Check the model number against the number indicated on the product.

Enter the gear ratio in the box (

) within the model name of the combination

type.

For the speed control motor, enter the code “

R

” in the box (

) within the model

name.

z

z

Induction motors

Model

Motor model

Capacitor model

Combination type

Pinion shaft type

2IK6

AW-

J

2IK6

GV-AWJ

2IK6

GV-AW

CH35FAUL2

2IK6

AW-

U

2IK6

GV-AWU

CH25FAUL2

2IK6

CW-

J

2IK6

GV-CWJ

2IK6

GV-CW

CH08BFAUL

2IK6

CW-

E

2IK6

GV-CWE

CH06BFAUL

3IK15

AW-

J

3IK15

GV-AWJ

3IK15

GV-AW

CH55FAUL2

3IK15

AW-

U

3IK15

GV-AWU

CH45FAUL2

3IK15

CW-

J

3IK15

GV-CWJ

3IK15

GV-CW

CH15BFAUL

3IK15

CW-

E

3IK15

GV-CWE

CH10BFAUL

4IK25

AW-

J

4IK25

GV-AWJ

4IK25

GV-AW

CH80CFAUL2

4IK25

AW-

U

4IK25

GV-AWU

CH65CFAUL2

4IK25

CW-

J

4IK25

GV-CWJ

4IK25

GV-CW

CH20BFAUL

4IK25

CW-

E

4IK25

GV-CWE

CH15BFAUL

5IK40

AW-

J

5IK40

GV-AWJ

5IK40

GV-AW

CH110CFAUL2

5IK40

AW-

U

5IK40

GV-AWU

CH90CFAUL2

5IK40

CW-

J

5IK40

GV-CWJ

5IK40

GV-CW

CH30BFAUL

5IK40

CW-

E

5IK40

GV-CWE

CH23BFAUL

5IK60AW-

J

5IK60GVH-AWJ

5IK60GVH-AW

CH200CFAUL2

5IK60AW-

U

5IK60GVH-AWU

CH180CFAUL2

5IK60CW-

J

5IK60GVH-CWJ

5IK60GVH-CW

CH50BFAUL

5IK60CW-

E

5IK60GVH-CWE

CH40BFAUL

5IK90AW-

J

5IK90GVR-AWJ

5IK90GVR-AW

CH280CFAUL2

5IK90AW-

U

5IK90GVR-AWU

CH250CFAUL2

5IK90CW-

J

5IK90GVR-CWJ

5IK90GVR-CW

CH70BFAUL

5IK90CW-

E

5IK90GVR-CWE

CH60BFAUL

4IK25SW-

4IK25GV-SW

4IK25GV-SW

−

5IK40SW-

5IK40GV-SW

5IK40GV-SW

−

5IK60SW-

5IK60GVH-SW

5IK60GVH-SW

−

5IK90SW-

5IK90GVR-SW

5IK90GVR-SW

−

z

z

Reversible motors

Model

Motor model

Capacitor model

Combination type

Pinion shaft type

2RK6

AW-

J

2RK6

GV-AWJ

2RK6

GV-AW

CH45FAUL2

2RK6

AW-

U

2RK6

GV-AWU

CH35FAUL2

2RK6

CW-

J

2RK6

GV-CWJ

2RK6

GV-CW

CH10BFAUL

2RK6

CW-

E

2RK6

GV-CWE

CH08BFAUL

3RK15

AW-

J

3RK15

GV-AWJ

3RK15

GV-AW

CH75CFAUL2

3RK15

AW-

U

3RK15

GV-AWU

CH60CFAUL2

3RK15

CW-

J

3RK15

GV-CWJ

3RK15

GV-CW

CH18BFAUL

3RK15

CW-

E

3RK15

GV-CWE

CH15BFAUL

4RK25

AW-

J

4RK25

GV-AWJ

4RK25

GV-AW

CH100CFAUL2

4RK25

AW-

U

4RK25

GV-AWU

CH80CFAUL2

4RK25

CW-

J

4RK25

GV-CWJ

4RK25

GV-CW

CH30BFAUL

4RK25

CW-

E

4RK25

GV-CWE

CH25BFAUL

5RK40

AW-

J

5RK40

GV-AWJ

5RK40

GV-AW

CH160CFAUL2

5RK40

AW-

U

5RK40

GV-AWU

CH120CFAUL2

5RK40

CW-

J

5RK40

GV-CWJ

5RK40

GV-CW

CH40BFAUL

5RK40

CW-

E

5RK40

GV-CWE

CH35BFAUL