H31

3-5

Coretronic Corporation

Color Adjust Procedure :

Notice : PC shall run 64 Intensity for Primary Colors Pattern of DMW Program.

1.

Power on.waiting for the "No Signal" show on the screen.

Press "Up" ,"Enter" button at the same time twice, then press "Left" ,"Enter" button at the same time twice.

2.

Connect PC signal, then press “ ” button to enter “Display Source” function.

3.

Press “ ” or “ ” to choose “Color Wheel Index” function.

4.

Press “+” or “-” button to adjust.

.

Note 1 : It may need to be used when you replace Main Board or Optical Engine alone.

3-2.3

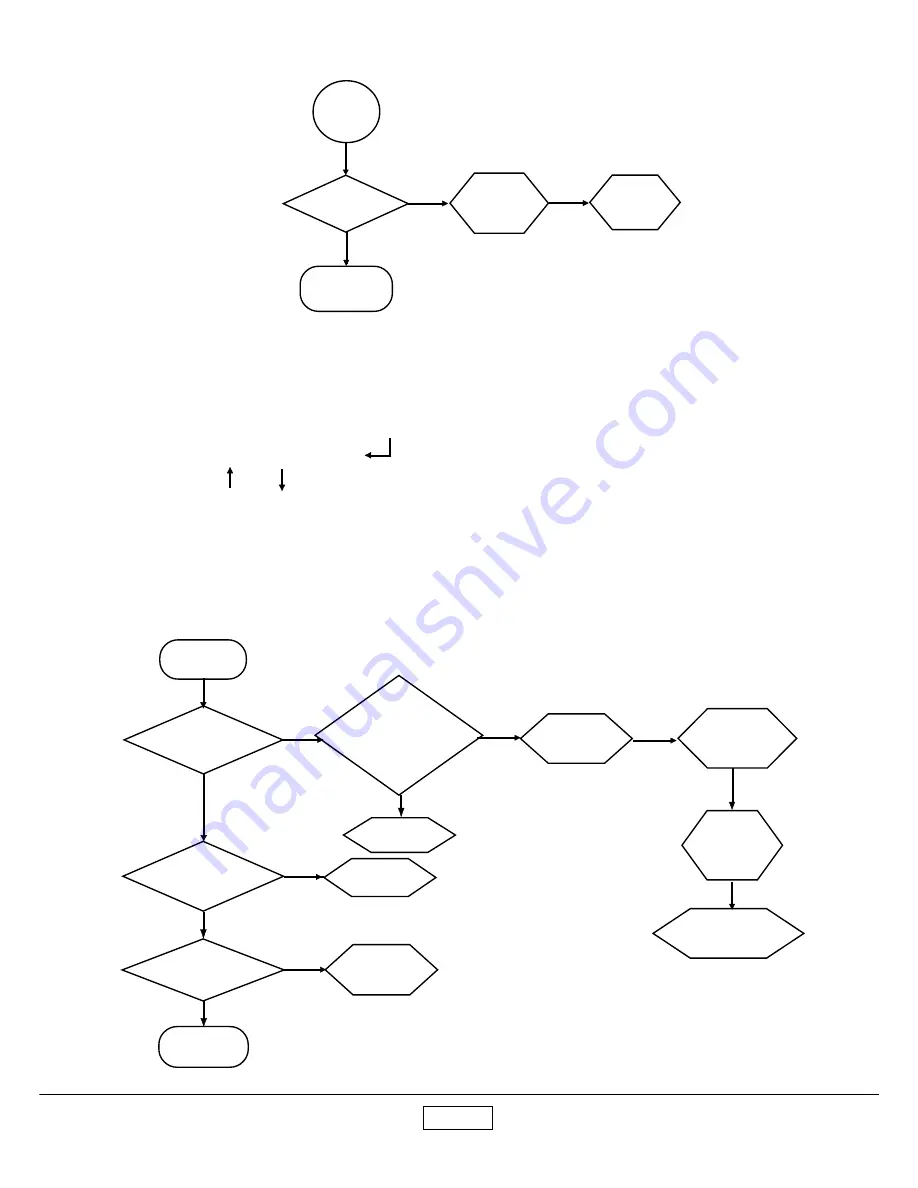

C. Function Troubleshooting(see 3-2.4 to check the Remote

Control Troubleshooting)

End

Have noise ?

Yes

No

No

Change

M/B

No

Adjust

tracking

1

FPC

End

Change Main

Board

Change

Keypad

Board

No

No

Start

No

Yes

Does OSD show

up ?

Can function be

adjusted ?

Change

Main board

No

No

Remote control

Can OSD data

be saved ?

No

Change

Main board

Yes

Yes

No

Change

Keypad Board

and Keypad Board

don’t work

Change

Main Board

Yes

Change

Summary of Contents for H31

Page 44: ...H31 6 7 Coretronic Corporation 6 Input is done after the OK message shows in the red circle ...

Page 46: ...H31 7 1 Coretronic Corporation Appendix A Exploded Diagram ...

Page 47: ...H31 7 2 Coretronic Corporation ...

Page 48: ...H31 7 3 Coretronic Corporation ...

Page 49: ...H31 7 4 Coretronic Corporation ...

Page 50: ...H31 7 5 Coretronic Corporation ...

Page 51: ...H31 7 6 Coretronic Corporation ...

Page 52: ...H31 7 7 Coretronic Corporation ...

Page 53: ...H31 7 8 Coretronic Corporation ...

Page 54: ...H31 7 9 Coretronic Corporation ...

Page 55: ...H31 7 10 Coretronic Corporation ...

Page 56: ...H31 7 11 Coretronic Corporation ...

Page 57: ...H31 7 12 Coretronic Corporation ...

Page 58: ...H31 7 13 Coretronic Corporation ...

Page 59: ...H31 7 14 Coretronic Corporation ...

Page 60: ...H31 7 15 Coretronic Corporation ...

Page 61: ...H31 7 16 Coretronic Corporation ...

Page 62: ...H31 7 17 Coretronic Corporation ...