Operation

Version 1.0.5 - 2020-12-09

43

Translation of original instruction

TX4414

EN

T

X

4414

_GB

_4.

fm

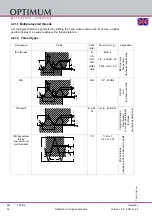

4.12.1 Clamping long workpieces

through the hollow shaft of the spindle

CAUTION!

Long rotating parts that have to protrude from the hollow shaft of the spindle must be

secured by the operator using suitable covers. A cover can be a sleeve that is mounted

on the headstock that, as a permanent safety device, completely covers the protruding

workpiece.

between the tips

CAUTION!

Long workpieces must be additionally supported. They are supported by the tailstock

sleeve and, if necessary, a rest.

with a lathe dog

CAUTION!

When clamping workpieces between the tips of the lathe while using a lathe dog, the

existing lathe chuck protection must be replaced with a circular lathe chuck protection.

Workpieces that require a high concentricity precision are machined between the centres. For

holding purposes, a centre hole is drilled into both plain machined faces of the workpiece.

Img. 4-7: Turning between centres

The lathe dog is clamped onto the workpiece. The driving bolt, which is screwed into the flange

for the lathe chuck, transmits the torque to the lathe dog.

The fixed centre glides into the centre hole of the workpiece on the spindle nose side. The fol-

low centre glides into the centre hole of the workpiece at the tailstock side.

Feed

Workpiece

Live centre

60

0

Workpiece

Lathe dog

Chuck flange

Driving bolt

Fixed

Centre 60

0