HOBO U20 Water Level Logger

2

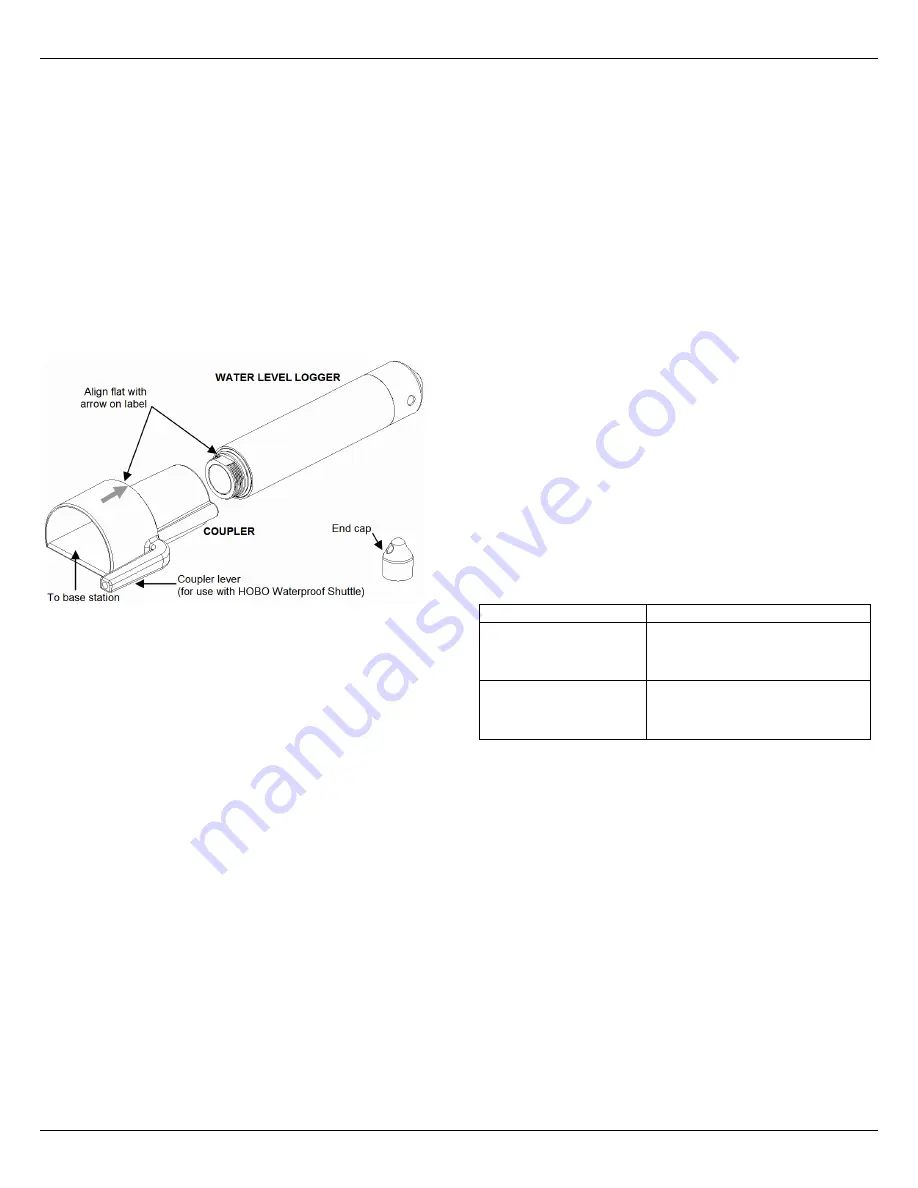

Connecting the logger

The HOBO Water Level Logger requires a coupler (Part #

COUPLER2-B) and USB Optic Base Station (Part # BASE-U-4) or

HOBO Waterproof Shuttle (Part # U-DTW-1) to connect to the

computer.

1. Install the logger software on your computer before proceeding.

2. Follow the instructions that came with your base station or shuttle

to attach the base station or shuttle to a USB port on the computer.

3. Unscrew the black plastic end cap from the logger by turning it

counter-clockwise.

4. Attach the coupler to the base station or shuttle, then insert the

logger into the coupler with the flat on the logger aligned with the

arrow on the coupler label. Gently twist the logger to be sure that it

is properly seated in the coupler (it should not turn).

5. If you are using the HOBO Waterproof Shuttle, briefly press the

coupler lever to put the shuttle into base station mode.

6. If the logger has never been connected to the computer before, it

may take a few seconds for the new hardware to be detected by the

computer.

7. Use the logger software to launch the logger.

8. You can check the logger’s status, read out the logger while it

continues to log, stop it manually with the software, or let it record

data until the memory is full.

Refer to the software user’s guide for complete details on launching,

reading out, and viewing data from the logger, including multiple

logging intervals and barometric compensation.

Important: USB communications may not function properly at

temperatures below 0°C (32°F)

or above 50°C (122°F).

Note:

The logger consumes significantly more power when it is

“awake” and connected to a base station or shuttle. To conserve

power, the logger will go into a low-power (sleep) mode if there has

been no communication with your computer for 30 minutes. To wake

up the logger, remove the logger from the coupler, wait a moment,

then re-insert the logger.

Note:

The first time you launch the logger, the deployment number

will be greater than zero. Onset launches the loggers to test them prior

to shipping.

Protecting the logger

•

Important! Do not attempt to open the logger housing!

Unscrewing the titanium nose cone of the logger will cause serious

damage to the pressure sensor and logger electronics. There are no

user serviceable parts inside the case. Contact Onset technical

support if your logger requires servicing.

•

This logger can be damaged by shock.

Always handle the logger

with care. The logger may lose its calibrated accuracy or be

damaged if it is dropped. Use proper packaging when transporting

or shipping the logger.

•

Biofouling and excessive marine growth on the logger will

compromise accuracy. Organisms that grow inside the sensor nose

cone and on the sensor itself can interfere with the sensor’s

operation and eventually make the sensor unusable. If the

deployment area is prone to biofouling, check the logger

periodically for marine growth.

•

Check a materials-compatibility chart before deploying the logger

in locations where untested solvents are present:

−

The logger is shipped with Viton O-rings installed. Viton has an

excellent resistance to most solvents and is suitable for

deployments in water that contain a mixture of most fuels,

solvents and lubricants. However, the Viton O-rings are sensitive

to polar solvents (acetone, ketone), ammonia, and brake fluids.

−

The black acetyl cap is provided to help protect the

communications window. Acetyl is resistant to most solvents,

fuels, and lubricants.

−

The polycarbonate communications window is sealed as an

additional barrier to water and dirt entering the logger housing.

Operation

A light (LED) in the communications window of the logger confirms

logger operation. The following table explains when the logger blinks

during logger operation:

When: The

light:

The logger is logging

Blinks once every one to four seconds (the

shorter the logging interval, the faster the

light blinks); blinks when logging a

sample

The logger is awaiting a start

because it was launched in

Start At Interval or Delayed

Start mode

Blinks once every eight seconds until

logging begins

Sample and event logging

The logger can record two types of data: samples and events. Samples

are the sensor measurements recorded at each logging interval (for

example, the pressure every minute). Events are independent

occurrences triggered by a logger activity, such as Bad Battery or Host

Connected. Events help you determine what was happening while the

logger was logging.

The logger stores 64K of data, and can record over 21,700 samples of

pressure and temperature.

Barometric Compensation

The HOBO Water Level Logger records absolute pressure, which is

later converted to water level readings by the software. In this

application, absolute pressure includes atmospheric pressure and water

head. Atmospheric pressure is nominally 100 kPa (14.5 psi) at sea

level, but changes with weather and altitude.

Left uncompensated, barometric variations could result in errors of

0.6 m (2 ft) or more. To compensate for barometric pressure changes,

you can use another HOBO Water Level Logger as a barometric

reference. The 0-4 m (0-13 ft) HOBO Water Level Logger

(U20-001-04) is a good barometric reference due to its smaller range,