Suitability for Use

Omron Companies shall not be responsible for conformity with any standards, codes or

regulations which apply to the combination of the Product in the Buyer’s application or

use of the Product. At Buyer’s request, Omron will provide applicable third party

certification documents identifying ratings and limitations of use which apply to the

Product. This information by itself is not sufficient for a complete determination of the

suitability of the Product in combination with the end product, machine, system, or other

application or use. Buyer shall be solely responsible for determining appropriateness of

the particular Product with respect to Buyer’s application, product or system.

Buyer shall take application responsibility in all cases.

NEVER USE THE PRODUCT FOR AN APPLICATION INVOLVING SERIOUS RISK

TO LIFE OR PROPERTY OR IN LARGE QUANTITIES WITHOUT ENSURING THAT

THE SYSTEM AS A WHOLE HAS BEEN DESIGNED TO ADDRESS THE RISKS, AND

THAT THE OMRON PRODUCT(S) IS PROPERLY RATED AND INSTALLED FOR THE

INTENDED USE WITHIN THE OVERALL EQUIPMENT OR SYSTEM.

OMRON Corporation

(Manufacturer)

Contact: www.ia.omron.com

Regional Headquarters

Shiokoji Horikawa, Shimogyo-ku, Kyoto, 600-8530 JAPAN

OMRON EUROPE B.V. (Importer in EU)

Wegalaan 67-69, 2132 JD Hoofddorp

The Netherlands

Tel: (31)2356-81-300/Fax: (31)2356-81-388

OMRON ELECTRONICS LLC

2895 Greenspoint Parkway, Suite 200

Hoffman Estates, IL 60169 U.S.A.

Tel: (1) 847-843-7900/Fax: (1) 847-843-7787

OMRON ASIA PACIFIC PTE. LTD.

No. 438A Alexandra Road # 05-05/08 (Lobby 2),

Alexandra Technopark,

Singapore 119967

Tel: (65) 6835-3011/Fax: (65) 6835-2711

OMRON (CHINA) CO., LTD.

Room 2211, Bank of China Tower,

200 Yin Cheng Zhong Road,

PuDong New Area, Shanghai, 200120, China

Tel: (86) 21-5037-2222/Fax: (86) 21-5037-2200

The application examples shown are suggestions. They however do not release the user from carefully checking whether the Safety door switch and its

set-up are suitable for the individual application.

The power supply for the safety door switch must provide protection against permanent overvoltage. To that effect, stabilized PELV supply units must be

used. The safety outputs can be directly integrated in the safety circuit of the control system. For applications of PL e / safety category 4 in accordance

with ISO 13849-1, the safety outputs of the safety door switch or safety door switch of the chain must be connected to a safety controller or safety relay

unit of the same Safety Category. Protection is not required when pilot wires are laid. The cables however must be separated from the supply and energy

cables. If the safety door switch is wired to relays or to non-safety relevant control components, a new risk analysis must be carried out.

If the safety door switch is connected to the safety input of a safety controller or safety relay unit, the controller must have a dual-channel monitoring time

of at least 100 ms and the accepted test pulse duration of at least 1 ms. Also, the cross-wire-short monitoring function must be disabled. Typically, a

switch-off time of 250 μs is reached with a 30-m connecting cable. The switch-off time of the safety door switch is additionally extended depending on the

cable length and the capacity of the cable used.

Note: Configuration of the safety controller

For the recommended safety controller, refer to the catalog of this product.

Individually coded safety door switches and actuators will require the

following teach-in procedure:

1. Keep the actuator away from the detection range and switch the safety

door switch's voltage supply off and back on.

2. Introduce the actuator in the detection range. The teach-in procedure is

signalled at the safety door switch, red LED on, yellow LED flashes (1 Hz).

3. After 10 seconds, the yellow LED gives brief cyclic flashes (3 Hz). Switch

off the supply voltage of the safety door switch. (If the voltage is not

switched off within 5 minutes, the safety door switch cancels the teach-in

procedure and signals a false actuator by 5 red flashes).

4. Switch the supply voltage back on. The actuator must be detected once

more in order to activate the taught actuator code. In this way, the

activated code is definitively saved.

For ordering suffix D41D-1, the executed allocation of safety door switch

and actuator is irreversible.

For ordering suffix D41D-2, the teach-in procedure for a new actuator can be

repeated an unlimited number of times. When a new actuator is taught, the

code, which was applicable until that moment, becomes invalid. Subsequent

to that, the safety outputs will be disabled for ten minutes, thus providing for

an increased protection against intentional tampering.

The green LED will flash until the expiration of the time (10 minutes) of the

enabling inhibit and the detection of the new actuator.

In case of power failure during the lapse of time, the 10-minutes tampering

protection time will restart.

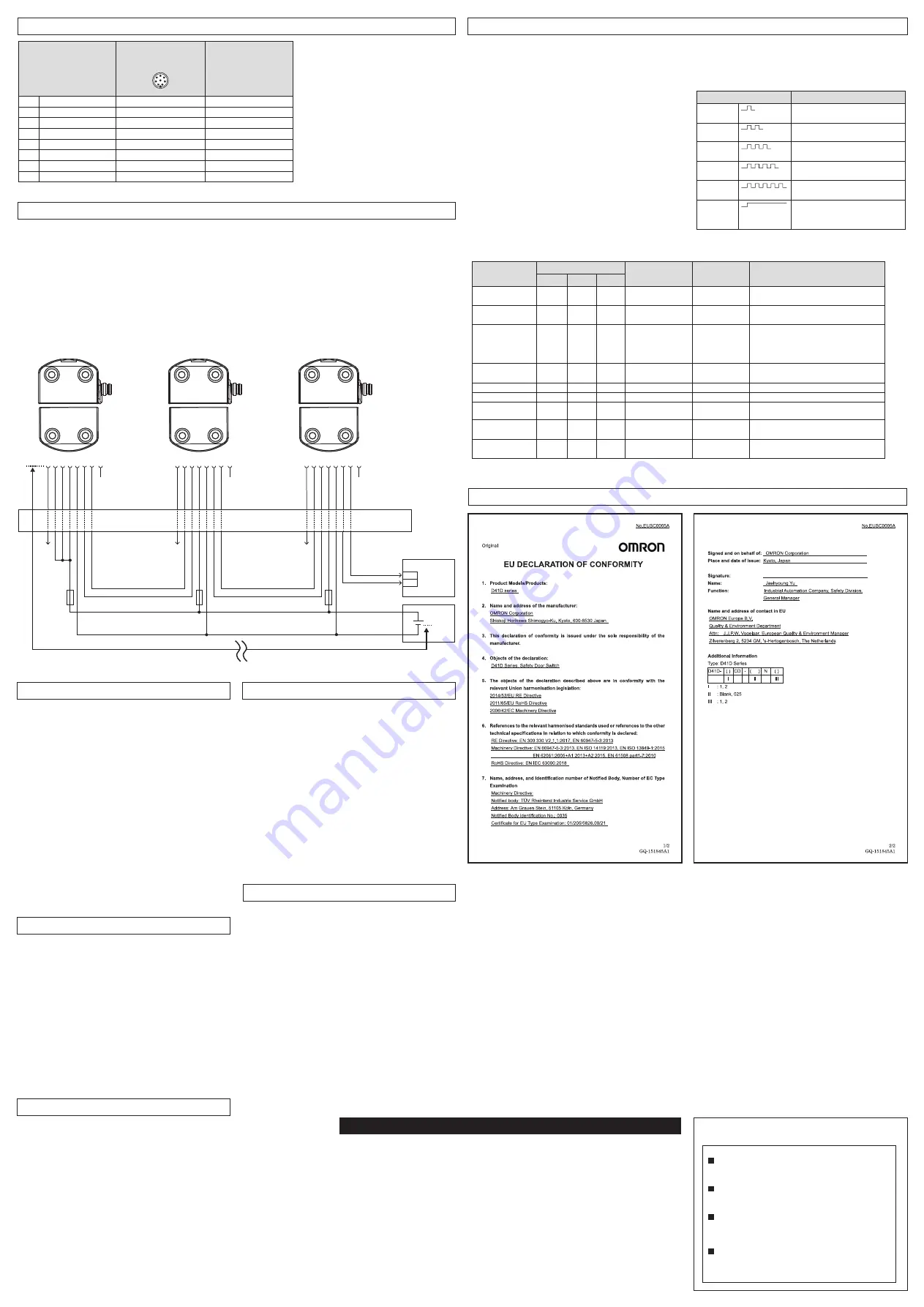

Connection

Wiring Examples

Teaching

The safety outputs can be connected to the safety circuit of the control

system. The opening of a guard door, i.e. the actuator is removed out of

the active zone of the safety door switch, will immediately disable the

safety outputs of the safety door switch. (For operating distances, refer to

Ratings and Specifications.)

Any error that does not immediately affect the functionality of the safety

door switch (e.g. too high ambient temperature, interference potential at

the safety outputs, cross-wire short) will lead to a warning message,

disabling of the auxiliary output and a delayed shutdown of the safety

outputs. (Refer to Troubleshooting.)

The safety outputs are disabled if the error warning is active for 30

minutes. The signal combination, auxiliary output disabled and safety

channels still enabled, can be used to stop the production process in a

controlled manner.

After fault rectification, the error message is reset by opening and

reclosing the corresponding guard door. The safety outputs enable and

allow a restart.

Operating Principle

Functional testing

The safety function of the safety components must be tested. The following

conditions must be previously checked and met:

1. Fitting of the safety door switch and the actuator.

2. Fitting and integrity of the power cable.

3. The system is free of dirt and soiling (in particular metal chips).

Maintenance

Maintenance frequency

SIL3 / PLe at least once a month

SIL2 / PLd at least once a year

(Daily inspection)

•

For each guard door, check that the machine stops when the guard door

opens.

(Inspection every 6 months)

1. Check the fitting and integrity of the safety door switch, the actuator and

the cable.

2. Remove possible metal chips.

3. Check that the cable is connected correctly and there is no problem.

Commission, Set-up and Maintenance

Disassembly

The product must be disassembled in a de-energized condition only.

Disposal

The product must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.

Disassembly and Disposal

Declaration of Conformity

Operating principle of the diagnostic LEDs

The safety door switch indicates the operating condition and faults by

means of three-color LEDs located in the lateral surfaces of the safety

door switch.

The green LED indicates that the safety door switch is ready for

operation. The supply voltage is on and all safety inputs are present.

Flashing (1 Hz) of the green LED signals that a voltage is missing on one

or both of the safety inputs (X1 and/or X2).

The yellow LED always signals the presence of an actuator within range.

If the actuator is operating near the limit of the differential travel range of

the safety door switch, the LED is flashing.

The flashing can be used to prematurely detect variations in the clearance

between the safety door switch and the actuator (e.g. sagging of a guard

door). The safety door switch must be adjusted before the distance to the

actuator increases and before the safety outputs are disabled, thus stopping

the machine. If an error is detected, the red LED will be activated.

Operating principle of the auxiliary output

An auxiliary output additionally indicates the operating condition (refer to

Table 1). The auxiliary output OUT can be used for central visualization or

control functions, e.g. in a PLC. It indicates the switching condition as

shown in Table 1.

Diagnostic Functions

Error

Errors, which no longer guarantee the function of the safety door switch (internal

errors) cause the safety outputs to be disabled within the risk time.

After the rectification of the error, the error message is reset by opening

the corresponding guard door.

Error warning

The auxiliary output can also be used to detect clearance variations between

the safety door switch and the actuator in the same way as the yellow LED.

An active fault is visualized by the red LED and causes the auxiliary output to

be disabled. The safety outputs are disabled after a maximum of 30 minutes if

the fault is not rectified. This signal combination, auxiliary output disabled and

safety channels still enabled, can be used to stop the production process in a

controlled manner.

Troubleshooting

Function

Pin assignment of

connector plug

M8/M12, 8-pole, A-coded

5

8

4

3

2

1

7

6

Color code of the OMRON’s

connector

(M8/M12 connector cable)

M8: D41D-8P5-CFM8-7**M

M12: D41L-8P5-CFM12-9**M

A1

U

e

1

WHITE

X1

Safety input 1

Note: 1. When using an OMRON cable, the tightening torque of the connector is 1 N•m

2

BROWN

A2

GND

3

GREEN

Y1

Safety output 1

4

YELLOW

OUT

Auxiliary output

5

GRAY

X2

Safety input 2

6

PINK

Y2

Safety output 2

7

BLUE

IN

without function

8

RED

*1. Referred to as a safety PLC.

Note: 1. Configuration of the safety

For the recommended safety controller, refer to the product catalog of this product.

LED indication (red)

Error cause

1 flash

pulse

Error output Y1

2 flash

pulses

Error output Y2

3 flash

pulses

Cross-wire short between Y1 and Y2

4 flash

pulses

Ambient temperature too high

5 flash

pulses

Incorrect or defective actuator

Continuous

red

Internal fault,

with yellow flashing teaching

procedure

Table 1: Diagnostic information for safety door switch with auxiliary output

Switch function

LEDs

Auxiliary output

Safety outputs

Note

Green

Red

Yellow

Y1, Y2

Supply voltage

On

Off

Off

0 V

0 V

Voltage on, no evaluation of the voltage

quality

Actuated

On

Off

On

24 V

24 V

The yellow LED always signals the presence

of an actuator within range.

Actuated in limit

area

On

Off

Flashes

(1Hz)

24 V

pulsed

24 V

Error warning,

switch actuated

Off

Flashes

On

0 V

24 V

After 30 minutes if the error is not rectified

Error

Off

Flashes

On

0 V

0 V

Refer to table with flash codes

Teach actuator

Off

On

Flashes

0 V

0 V

Safety door switch in teaching mode

Tampering protection

time (*1)

Flashes

Off

Off

0 V

0 V

10 minutes pause after re-teaching

Error in input circuit

*1. Refer to Teaching.

X1 and/or X2

Flashes

(1Hz)

Off

Off

0 V

0 V

Example: door open; a door in the safety

circuit upstream is also open.

Error in input circuit

X1 and/or X2

Flashes

(1Hz)

Off

On

24 V

0 V

Example: door closed, a door in the safety

circuit upstream is open.

D41D series connection example

The safety door switch must be adjusted

before the distance to the actuator increases

and before the safety outputs are disabled,

thus stopping the machine.

1 3

2

5

6

8

X1

4

Y1

X2

7

Y2

OUT

A1 A2

1 3

2

5

6

8

X1

4

Y1

X2

7

Y2

OUT

A1 A2

1 3

2

5

6

8

X1

4

Y1

X2

7

Y2

OUT

A1 A2

Nth D41D

2st D41D

1st D41D

Terminal block,

etc.

Safety outputs

between switch and power supply

S-PLC(*1)/PLC

S-PLC(*1)/PLC

S-PLC(*1)/PLC

IN1

IN2

24 VDC

GND

Safety

Controller