OM9300F Technical Manual

Rev.

1.0

Document No.: 19B00270

Date: Jan 09, 2018

Page: 12

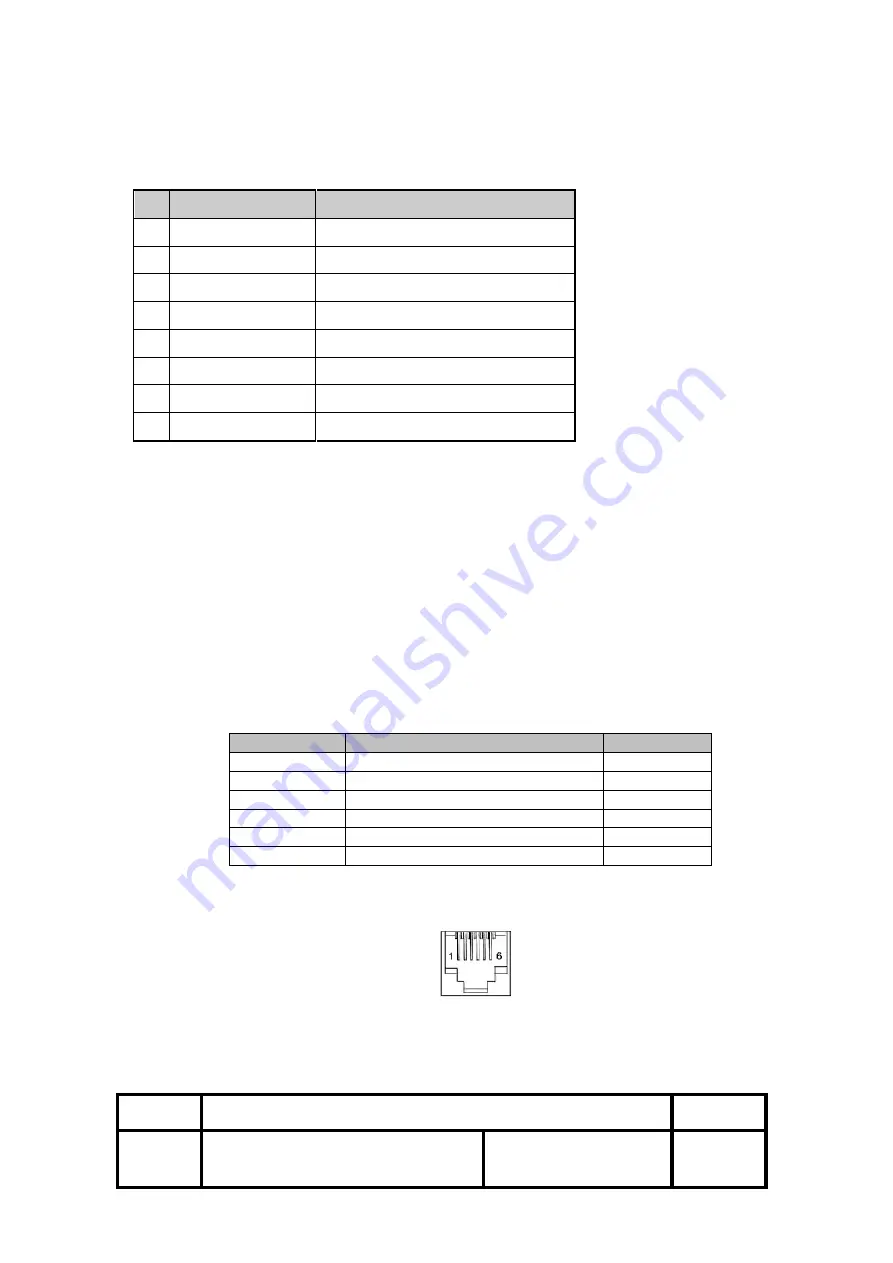

-Ethernet Interface

PIN

SIGNAL

I/O

1

Data Out +

Output Data +

2

Data Out -

Output Data -

3

GND

Ground

4

Data IN +

Input Data +

5

Data IN -

Input Data -

6

N.C

7

N.C

8

N.C

3.4 Drawer Kick-out Connector (Modular Connector)

The pulse specified by ESC p or DLE DC4 is output to this connector. The

host can confirm the status of the input signal by using the

DLE EOT

,

GS a

, or

GS r

commands.

1) Pin assignments:

Refer to Table 2.2.2

2) Connector model:

Printer side:

RJ11 6P6C, AMP P/N 115837

User side:

6-position 6-contact (RJ12telephone jack)

< Drawer Kick-out Connector Pin Assignments >

Pin Number

Signal Name

Direction

1

Frame GND

-

2

Drawer kick-out drive signal 1

Output

3

Drawer open/close signal

Input

4

+24V

-

5

Drawer kick-out drive signal 2

Output

6

Signal GND

-

+24V is output through pin 4 when the power is turned on. However, pin 4 must by

used only for the drawer.

< Figure 3.1 Drawer Kick-out Connector >

3) Drawer kick-out drive signal

Output signal: Output voltage: Approximately 24V

Output current: 1A or less