omega.com

e-mail: [email protected]

For latest product manuals:

omegamanual.info

User’s Guide

M-4590/1107

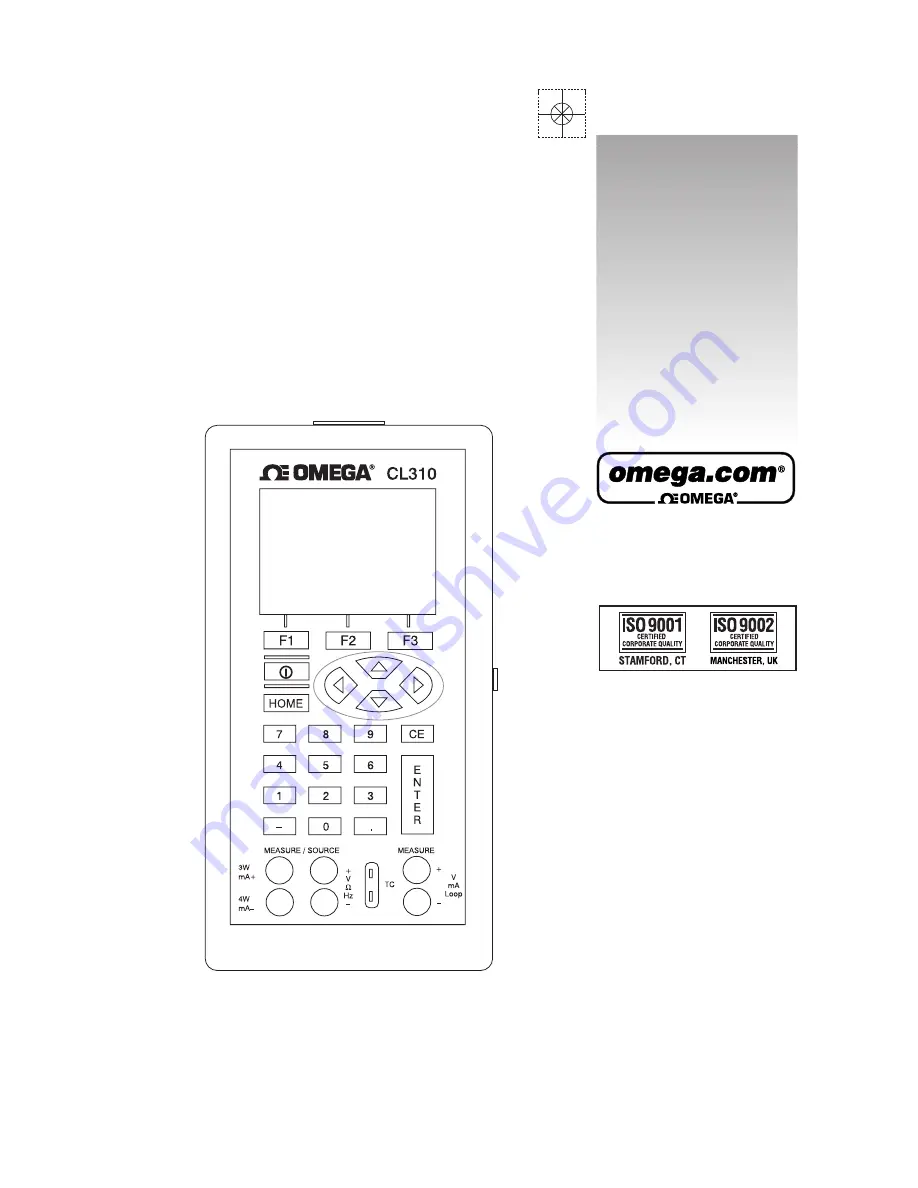

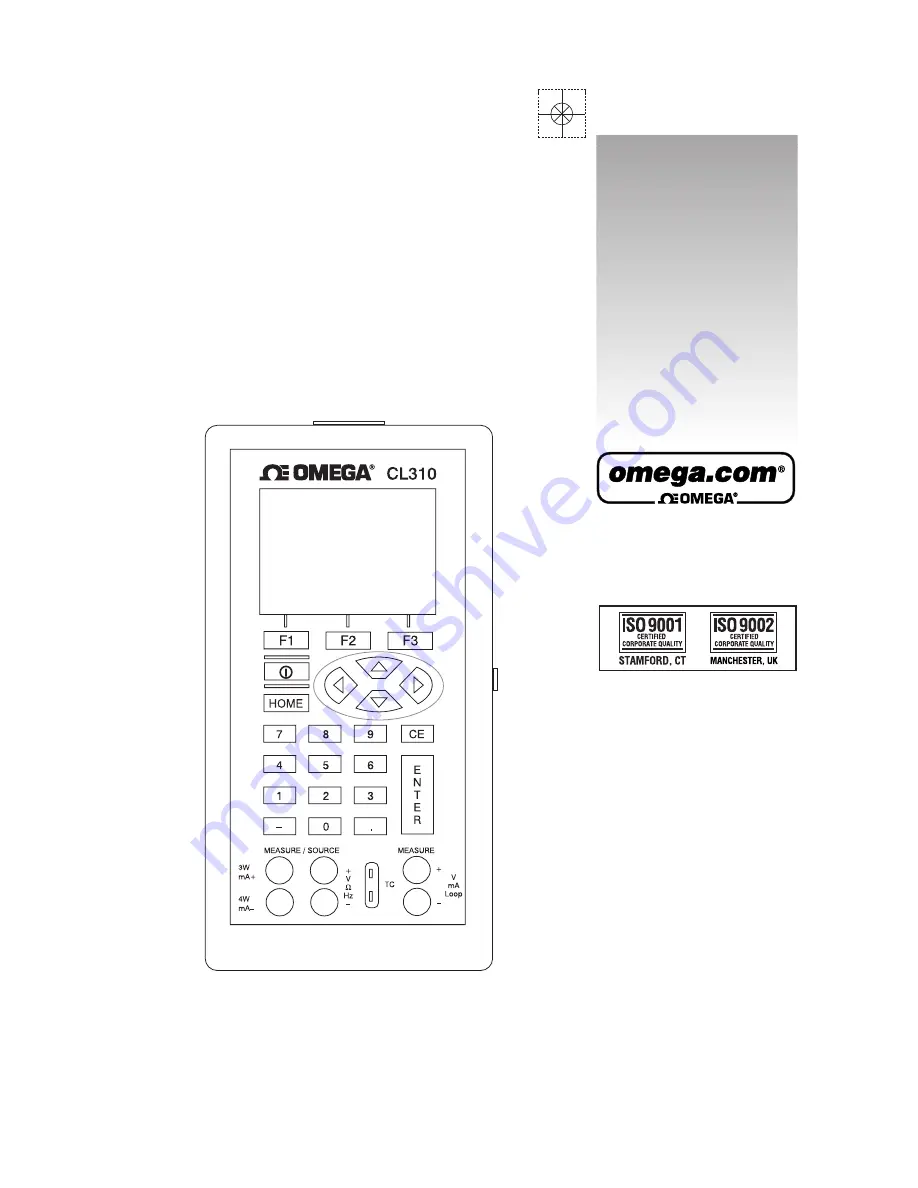

CL310

Shop online at

omega.com

e-mail: [email protected]

For latest product manuals:

omegamanual.info

User’s Guide

M-4590/1107

CL310

Shop online at