EMD Installation and operating manual

24

www.omega-air.si

Troubleshooting

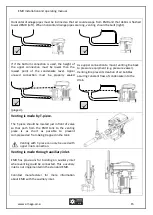

After powering EMD, it enters overload mode and afterwards, it enters alarm mode.

During power down, large amount of condensed water has collected in compressed air system. Hold the

test button until all the water is drained.

EMD enters alarm mode occasionally. But, it gets back to normal mode immediately after all the water is

drained by holding the test button.

The reason might be extremely hot and moist day.

EMD is undersized and it should be replaced by bigger drain.

Pressing test button does not open the valve.

Check electric power and cable connections.

Check the fuse.

There is no LED signal although the valve could be opened by pressing test button.

The LED is not bright enough to be seen in daylight.

Fuse is blown.

Check integrity of electronics. Replace the fuse if there is no visible damage on electronics.

Air leaks through the drain pipe even when EMD is disconnected from power.

There might be debris in valve or valve may be damaged. Check integrity of strainer. The valve assembly

should be cleaned or replaced by authorized person.

Long flashes of green LED indicate full tank although the tank is empty.

Clean the water level sensor surface.

EMD is in alarm and there is no water drained, only air.

Clean the water level sensor surface.

EMD is in alarm and valve opens, but there is no water or air drained.

Path between EMD’s tank and valve is clogged. Clean the tank, strainer and valve assembly. Replace

strainer or valve assembly when they are damaged.

Condensed water is not drained automatically. Instead, it is drained only when test button is pressed.

If the amount of drained water is small, then the water in tank hasn’t reached the threshold, yet.

If water is drained during pressing the test button, then we should check the piping in front of EMD.

Pipe’s inclination is too small or there may be debris in the pipe so that air in the EMD’s tank is trapped.

When the test button is pressed, this air escapes through drainage and makes place for condensed

water. Solution: clean pipe, build venting. Switch timer function on.

Red LED is flashing.

EMD is in one of production modes or there is some other error. First, check supply voltage. Then,

contact supplier.