8

Operation

LIGHTING THE PILOT

The manifold units are equipped with standing pilots and each should be lit immediately after the gas is

supplied to the equipment.

1.

Before attempting to light the pilots, turn off the main gas valve to the equipment and wait 5 minutes to

clear the gas.

2.

Turn off all gas control knobs.

3. Turn on control valve and light all pilots.

4.

The pilot burner must be lit from the top. Hold an ignition source and light the pilot. When the flame is

stable, remove ignition source.

5.

Turn off the main gas valve to shut down the equipment.

There is one pilot for each burner. The broiler is equipped with standing, unmonitored pilots. Gas will flow from

the pilots as soon as the main gas supply to the unit is turned on. Standing pilots should be adjusted to provide

a slight yellow tip on the f lame. Air shutters on the main burners must be individually adjusted to provide a blue

flame. All traces of yellow should be adjusted out of the burner flame.

The broiler is a free vented appliance. All products of combustion and the heat generated by the burners pass

through the grates. When meat is placed on the grates, this blocks the venting and causes a temperature

build-up.

PILOT FLAME HEIGHT ADJUSTMENT

• The pilot flame on the equipment has been factory adjusted. When adjustment is necessary, adjust the

pilot flames as small as possible but high enough to light the burner immediately when the burner valve is

turned to the highest setting. Access to the pilot flame adjustment screw is obtained through the holes in

the front panel.

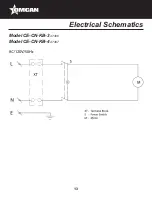

Turn the main power switch ON. Each power switch controls each spit independently. Allow the broiler to

preheat for 30 minutes. Each spit is able to cook 5 chickens in 45 minutes. After 30 minutes of burn-in,

equipment is ready for use.

OPERATION

1. To ignite the burners, depress and turn the gas control knob to high position.

2. Turn on the motor and chamber light switch when in need.

SHUTDOWN INSTRUCTIONS

After cooking is done, please turn the valve to off position and turn off the motor switch, light switch and main

power switch, then cut off the gas and power supply.