7

Maintenance

Troubleshooting

1. Cabinet cleaning: The product should be cleaned once a week with the power supply disconnected. When

cleaning, use mild rinsing water and non-corrosive detergent. Do not wash it directly under the faucet.

2. De-dust the condenser to clean. The condenser should be cleaned every three months with power supply

disconnected. To clean the condenser, remove the dust on the bottom panel for air suction and remove the

dust on the cooling fan of the condenser with wire brush or high pressure air gun.

3. Check for any leaks as well as oil stains. This will indicate that there is repair needed, to be performed by

trained personnel.

4. Frequently observe the operation of the product. In case of abnormal noise, smell or smog, cut the power

supply immediately and call for a trained technician. Do not restart the product before the problem is fixed.

5. Omcan Inc. will not be responsible for any accidents that occur because of failure to follow the regular

maintenance.

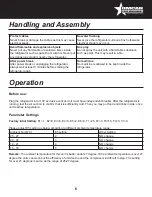

Troubles

Causes

Solutions

Strange noise under the bottom

shelf.

Fan blade is broken.

Power off and fix the blade.

No refrigeration in spite of normal

operation.

Unit off.

Power on.

Defrost process.

Stop defrost cycle.

Refrigerant leaking.

Patch the leak and refill refrigerant.

Unit failure.

Call for professionals.

Weak air from curtain, and higher

cabinet temperature.

Evaporator blocked by frost.

Increase defrost frequency.

Inside fan damaged.

Replace the fan.

Too low set point of temperature

controller.

Adjust the set point.

Vent blocked by storage.

Remove the storage.

Normal air curtain, but higher

cabinet temperature.

Insufficient refrigerant.

Refill the refrigerant.

Too high set point of temperature

controllers.

Adjust the set point of the

temperature controller.

The wind curtain is disturbed by

strong air flow.

Removing the disturbing factors.

Ambient temperature or humidity

beyond standards.

Improve the conditions.

Evaporator Pan overflowing.

Heating pipe for evaporator pan is

damaged.

Replace the heating pipe.

Water-level controller failure.

Replace the water-level controller.

Ambient temperature or humidity

beyond standards.

Improve the conditions.

Summary of Contents for 25825

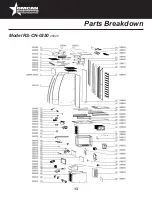

Page 13: ...13 Parts Breakdown Model RS CN 0250 25825 ...

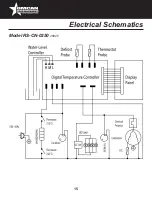

Page 15: ...15 Model RS CN 0250 25825 Electrical Schematics ...

Page 16: ...16 ...

Page 18: ...Notes ...

Page 19: ...Notes ...