17

Cleaning and Servicing

Deposits and residual adhesive on the transport rollers can influence the

results of the laminating process. Therefore, the transport rollers must be

cleaned periodically after use:

To do this, insert a folded piece of paper in the insertion slot. Residual

adhesive is removed and taken up by the paper when ejected. Repeat the

process several times.

Disconnect the power plug before starting to clean the unit with a damp

cloth. If necessary, the housing can be cleaned using a cloth moistened with

clean water with a little mild soap applied. Never use any solvents or

aggressive cleaning agents.

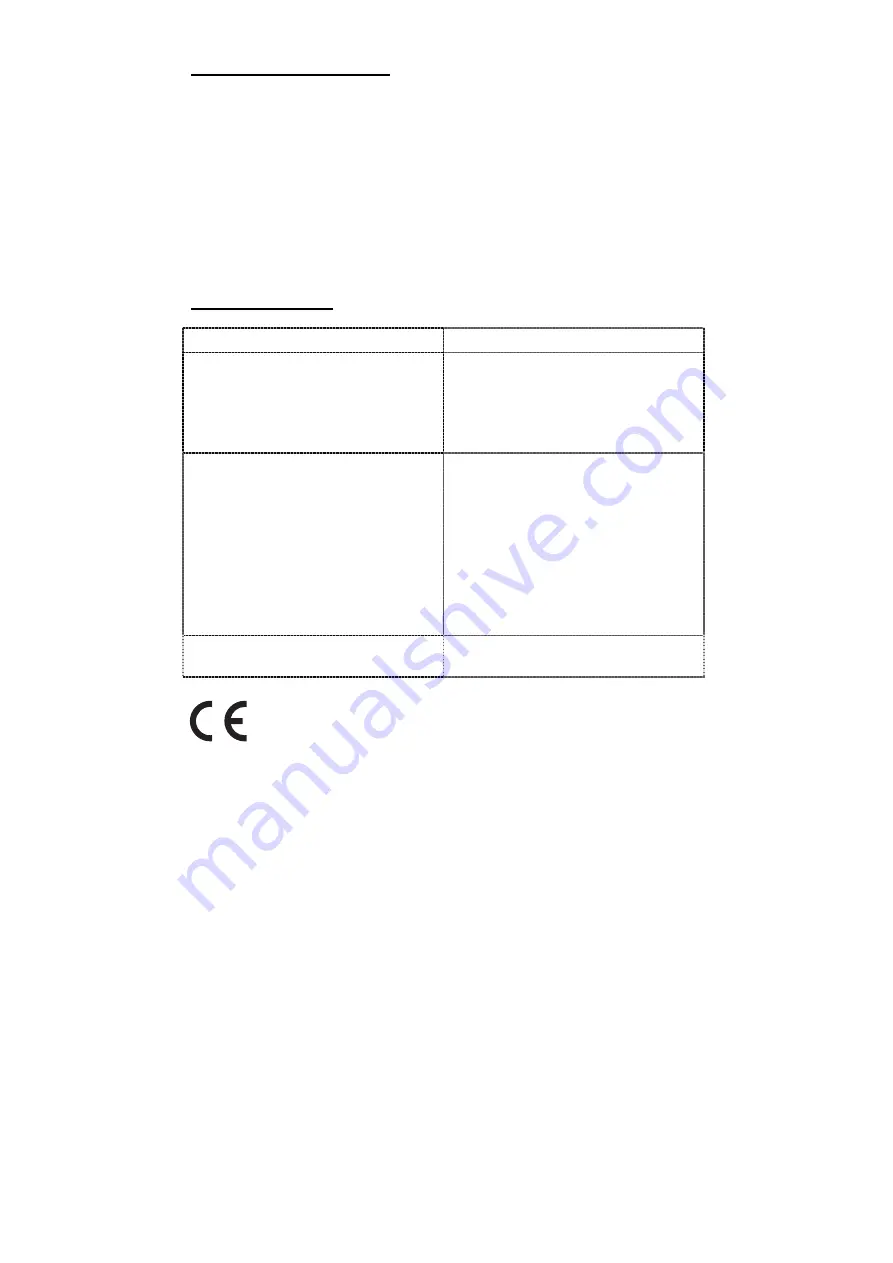

Troubleshooting

Fault Corrective

measures

•

Red LED (POWER) does not light

up

•

Unit does not respond

•

Check that the power plug has

been properly connected to the

power socket.

•

If the fault cannot be cleared,

contact our hotline.

•

Foil jam

•

Check the foil pockets being used

are the correct size.

•

Only use pouches of the size

specified.

•

Ensure that the pouch has been

inserted correctly in the unit.

•

To clear the fault, follow the

instructions in the Section "Clearing

Foil Jams".

•

Laminated foil is not completely

transparent

•

Laminate the same foil again to

improve the lamination result.

Conformity of the equipment to the

EU directives is confirmed by the

CE symbol.

Summary of Contents for A 4040

Page 11: ...11 Vertriebs GmbH...

Page 48: ...48...