19. Image quality problem

Field Service Ver. 1.0 Jun. 2008

348

T

roubleshooting

19.3.25

Printer monocolor: blank copy, black copy

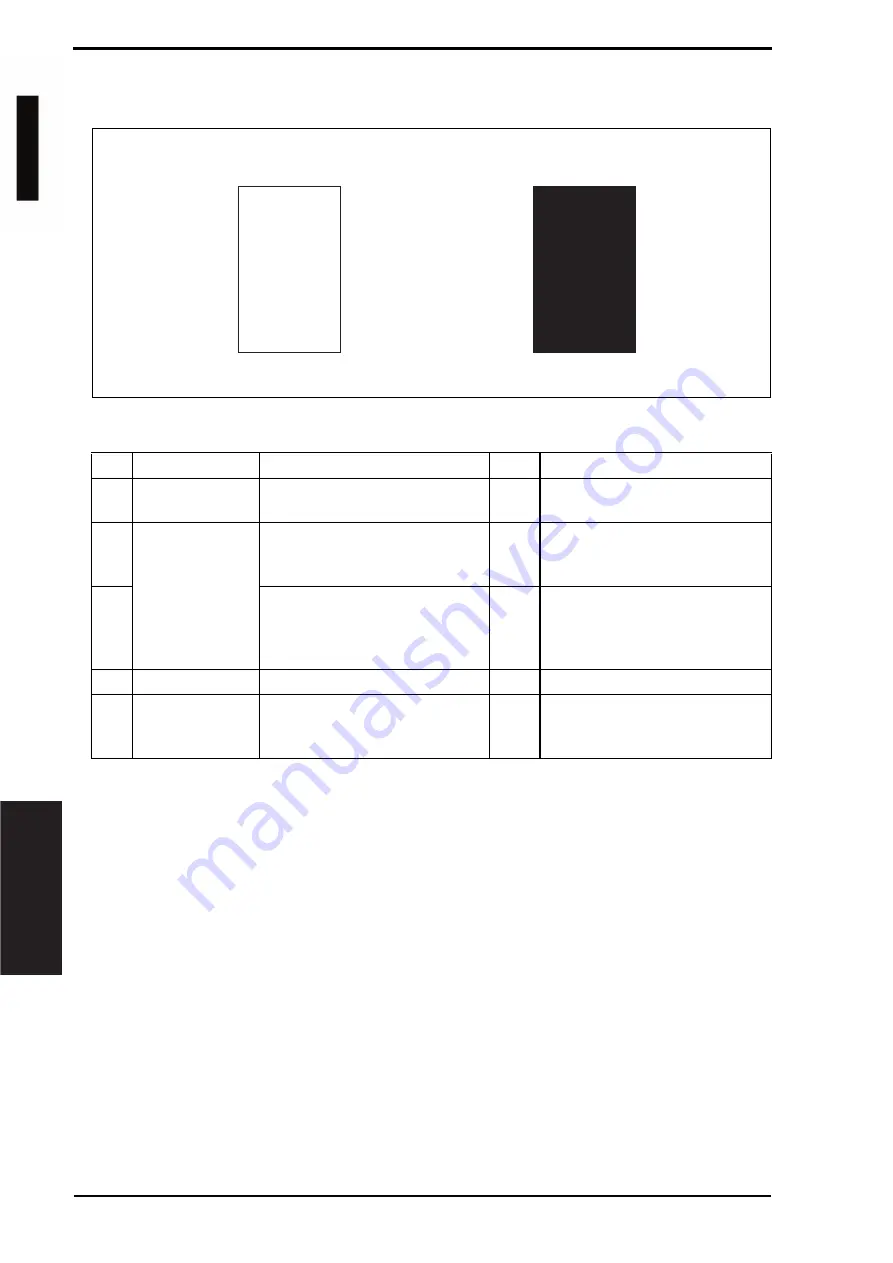

A. Typical faulty images

B. Troubleshooting procedure

A02EF4C518DA

Blank copy

Black copy

Step

Section

Check item

Result

Action

1

Image check

A blank copy occurs.

YES

Check PH unit connector for

proper connection.

2

Imaging unit

Coupling of IU drive mechanism

is installed properly.

NO

Check and correct drive

transmitting coupling.

Change IU.

3

The PC drum charge corona

voltage contact or PC drum

ground contact of the imaging unit

is connected properly.

NO

Check, clean, or correct the con-

tact.

4

High voltage unit

Connector is connected properly.

NO

Reconnect.

5

The problem has been eliminated

through the check of step 4.

NO

Change high voltage unit.

o

Change printer control board

o

Change PH unit.

d-Color MF201

Service Manual Y109660-1