10-2

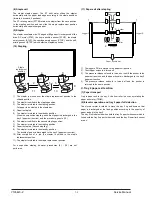

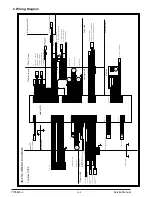

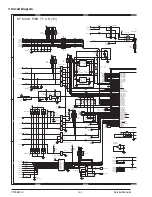

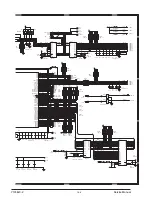

2. Wiring Diagram

1

2

4

5

6

7

8

9

10

11

12

13

14

15

16

GND1

+24V

GND1

+24V

GND1

CNA(B16B-PHDSS)

GND2

GND2

+5V

N.C.

TXD-FIN2

RXD-FIN2

+24V

DTR-FIN2/

DSR-FIN2/

RES-FIN2

FGS-FIN/

T1PF/

+5V

1

2

CNI(S3B-PH-K-S)

3

GND2

1

2

3

T1PF

3

STTM

15

17

19

14

13

11

2

1

T2OM/A

+24V

STUMB

STUMA

STTM-

4

3

22

SCRS/

+24V1

T2OM/B

16

STUM/B

STUM/A

+24V

+24V

N.C.

1

10

18

20

12

9

8

7

1

2

SCRS

6

5

21

+24V

N.C.

+24V

T2OMB

T2OMA

STTM+

+24V

2

CNC(B32B-PHDSS)

REAR Frame

+5V

EVM+

+24V

T2UP

T2PD

GND2

T2S/

5

6

4

3

2

1

11

7

8

9

10

12

13

14

EVM-

+5V

GND2

+5V

GND2

T2DN

Elevator UNIT

6

4

5

MME/

CND(B6B-PH-K-S)

MMCK

2

3

MMLK

1

GND1

2

3

1

4

5

MM

2

5

7

16

12

STSP/

13

4

1

STM-

STM-

8

3

10

14

STM+

9

CNE(B16B-PHDSS)

(STTD)

STM+

11

GND2

GND2

STHP/

STLS

STNC

STUHP

+5V

+5V

6

15

5

6

2

4

1

3

7

STM

8

9

10

11

12

13

STLS

STHP

STSP

STAPLER

4

6

8

COM1

7

2

PID/

FGS/

1

CNG(B9B-PH-K-S)

+24V

5

GND2

3

5

1

2

3

4

6

7

8

+24V

T2S/

+5V

T2UP

GND2

+5V

T2DN

GND2

+5V

T2PD

GND2

(SMP-18V-BC)

COM1

GND2

PID/

+24V

FGS/

Relay UNIT

SPS/

+24V

18

4

6

9

JFMB

19

8

15

7

2

1

13

11

20

14

10

17

12

16

5

+24V1

PPS/

3

21

22

23

24

+24V

JFM/B

JFM/A

JFMA

+24V

+24V

JRMB

JRM/B

JRM/A

JRMA

+24V

+24V

PSMB

PSM/B

PSM/A

PSMA

+24V

+24V

17

12

20

JFHP

18

6

4

16

2

SCPD/

13

9

PSHP

11

7

19

14

3

5

8

1

15

10

21

22

23

24

25

26

27

28

JRHP

COM2

SCID/

STTHP1/

PPD/

CNF(B24B-PHDSS)

CNH(B32B-PHDSS)

+5V

GND2

+5V

GND2

+5V

GND2

+5V

GND2

GND2

+5V

GND2

+5V

STTHP2/

GND2

COM3

GND2

+5V

GND2

SCID2/

29

30

31

32

PSM

1

2

3

4

5

6

JFM

1

2

3

4

5

6

JRM

1

2

3

4

5

6

FRONT Frame

STAPLE Compiler

3

JFHP

2

1

1

JRHP

3

2

1

3

2

PSHP

3

1

2

3

SCID

2

1

SCPD

STAPLER UNIT

To Option DCPS

Upper PG

FG

SMR-18V-N

(SMP-09V-BC)

STNC

GND2

+5V

DOPD/

FGS

DOPD

1

2

3

1

2

9

+5V

DOPD/

GND2

3

2

1

PID

MAIN PWB TF

23

24

25

26

GND2

POD/

1

T2S

2

1

T2UP

2

3

1

T2DN

2

3

1

T2PD

2

3

SCID2

2

1

3

GY

OR

RD

RD

BL

PL

BR

PK

RD

RD

PL

BL

PK

BR

PL

BL

GY

GY

RD

GY

RD

GY

RD

BL

GY

OR

GY

OR

RD

BL

RD

BR

RD

BL

RD

BR

OR

GY

PK

OR

OR

GY

GY

PL

BR

RD

GY

BL

PL

BR

OR

GY

BL

OR

PL

GY

RD

BR

RD

RD

BL

PL

BR

PK

RD

RD

BL

PL

BR

PK

RD

RD

BL

PL

BR

PK

RD

RD

OR

GY

GY

GY

GY

GY

GY

GY

GY

GY

OR

OR

OR

OR

OR

OR

OR

OR

RD

RD

BL

PL

BR

PK

BL

BL

PL

BR

PK

BL

PL

OR

GY

BL

OR

PL

GY

RD

BR

RD

BL

BL

RD

GY

RD

BR

RD

RD

BR

OR

PK

GY

OR

PL

GY

OR

BR

GY

RD

BR

RD

BR

RD

RD

RD

RD

OR

YE

BR

BK

OR

YE

BR

OR

YE

BR

BK

BK

RD

1

3

2

POD

OR

GY

15

16

17

18

N.C.

N.C.

N.C.

GY

BR

(SMP-10V-BC)

1

2

3

5

6

7

8

9

10

+5V

+24V1

GND2

+24V2

4

STTHP1/

+5V

STTHP2/

GND2

+24V

PPS/

PL

PPS

1

3

RD

BR

DSW2

2

RD

RD

1

OR

3

1

GY

2

STTHP1

BL

GY

STTHP2

2

3

1

OR

PL

RD

1

PPD

3

2

BR

2

RD

1

SPS

SCGS/

1

BR

RD

SCGS

2

BR

RD

RD

S Paper Entry UNIT

OR

+24V

RXD-FIN2

TXD-FIN2

DSR-FIN2/

N.C.

DTR-FIN2/

+5V

GND2

GND2

GND1

+24V

GND1

+24V

GND1

2

+24V

5

13

15

FGS-FIN/

14

10

16

3

4

1

RES-FIN2

17

8

9

11

12

6

18

FG

7

N.C.

27

28

29

30

31

32

+5V

GND2

POD/

N.C.

N.C.

DSW1

2

1

3

RD

YE

2

BR

6

1

4

RD

OR

5

BK

STUM

EVM

2

1

+5V

BL

BL

FG

CNB(B6B-PH-K-R)

6

4

1

3

5

T2OM

2

1

2

3

4

5

6

GND2

+24V2

GND2

GND2

GND2

TEST

PL

BR

PK

GY

OR

BL

OR

PL

GY

STUHP

1

2

3

FG

GY

GY

SCID2/

GND2

COM3

(SMP-03V-BC)

1

2

3

9

FG

FG

+24V1

N.C.

N.C.

N.C.

FG

FG

GY

Left cover UNIT

GY

GY

BR

OR

BK

RD

WH

YE

GY

Tray 1 full detection

Compiler door SW

ST shift motor

Elevator motor

ST rotation motor

Roller pressure relief solenoid

Tray 2 solenoid

Tray 2 upper limit detection

Tray 2 lower limit

detection

Tray 2 paper detection

Tray 2 paper exit

detection

Tray 2 paper exit motor

Main motor

Elevator stay

Jogger F.H.P. detection

Jogger R.H.P. detection

Pusher H.P. detection

Compiler paper detection

Compiler paper entry detection

Compiler gate

solenoid

Compiler paper entry detection 2

Stopper solenoid

Staple replacement door SW

ST rotation detection 1

ST rotation detection 2

Paper hold solenoid

Jogger F motor

Jogger R motor

Pusher motor

Paper entry detection

Interface door open/close detection

Paper entry reverse gate solenoid

ST unit H.P. detection

Paper hold detection

1-D4

1-D2

A

A

B

B

C

C

D

D

E

E

4

4

3

3

2

2

1

1

AR-FN6 WIRING DIAGRAM

* "# $%&'()

Y105

620

-

2

Service Manual