Bottom Feed Continuous Forms

Bottom Feed Continuous Forms

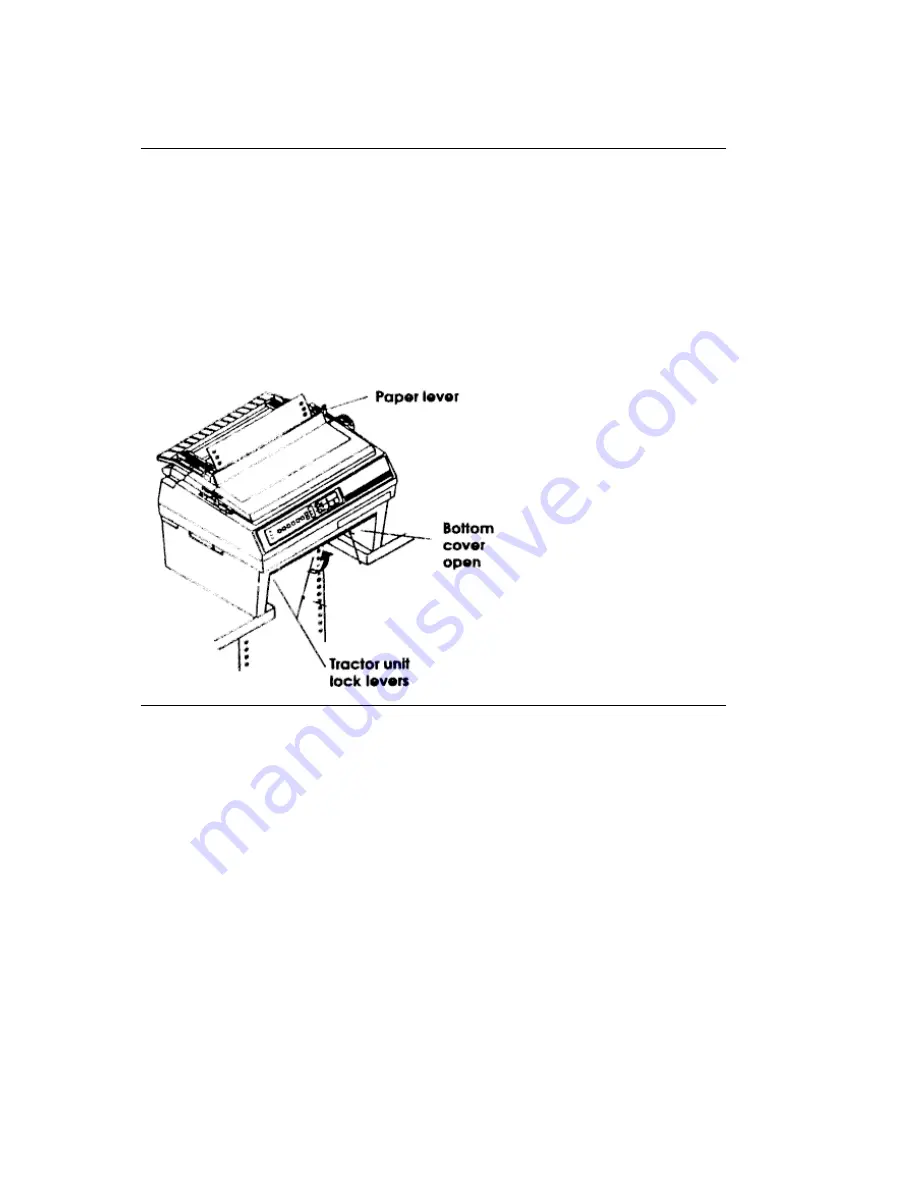

1. Make sure the paper lever is set for single-sheet paper

(back).

2. Put a stack of continuous forms paper below the printer.

3. Open the door on the front of the tractor unit.

4. Open the tractor covers and set the paper on the pins.

5. Pull the lock lever forward to unlock the tractor.

6. Slide the tractor to adjust to the width of the paper, then push the lock lever back to lock the

tractor in position.

7. Close the tractor covers and the unit door.

8. Make sure the printer is on and selected. Press the FORM FEED button to advance the paper

into the printer.

ML3410 ( 96-02-07 )