ML1120/ML1190 User’s Guide - Getting started > 10

3.

Platen Knob: turn to move or eject the paper.

4.

Paper Thickness Lever: set according to the thickness of the

paper. There is also a setting to facilitate ribbon replacement.

5.

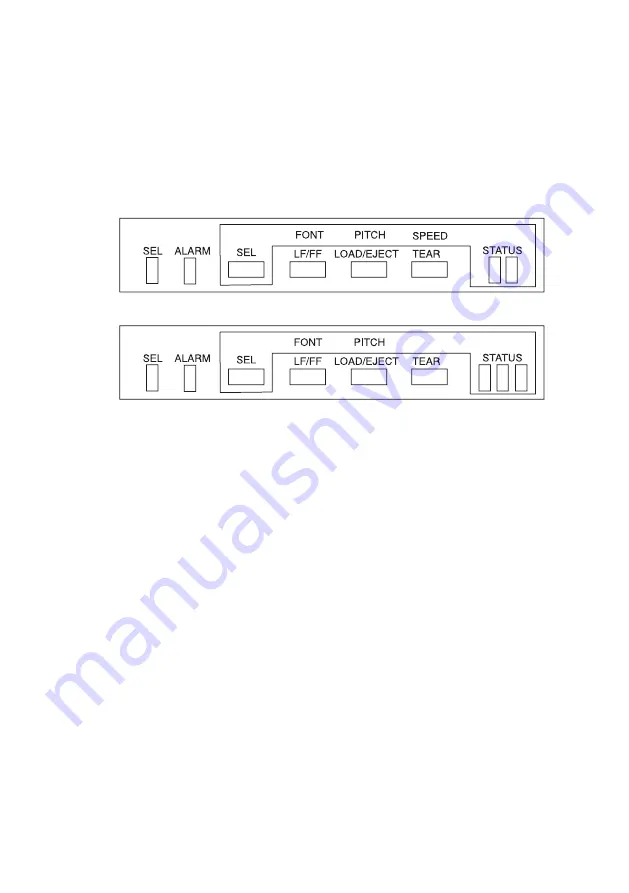

Control Panel: contains button switches and indicators

(described in detail later) that allow you to operate the printer.

ML1120

ML1190

6.

Power Switch: to turn the printer power ON/OFF.

7.

Ribbon Cartridge: holds the printer ribbon.

Summary of Contents for ML1190

Page 1: ...User s Guide ML1120 ML1190 ML1120 ML1190...

Page 89: ...43471832EE Rev1...