Soldering Iron Tip Plating Failures

7

© 2006 OK International. Technical Note v2.2; 05/14/07

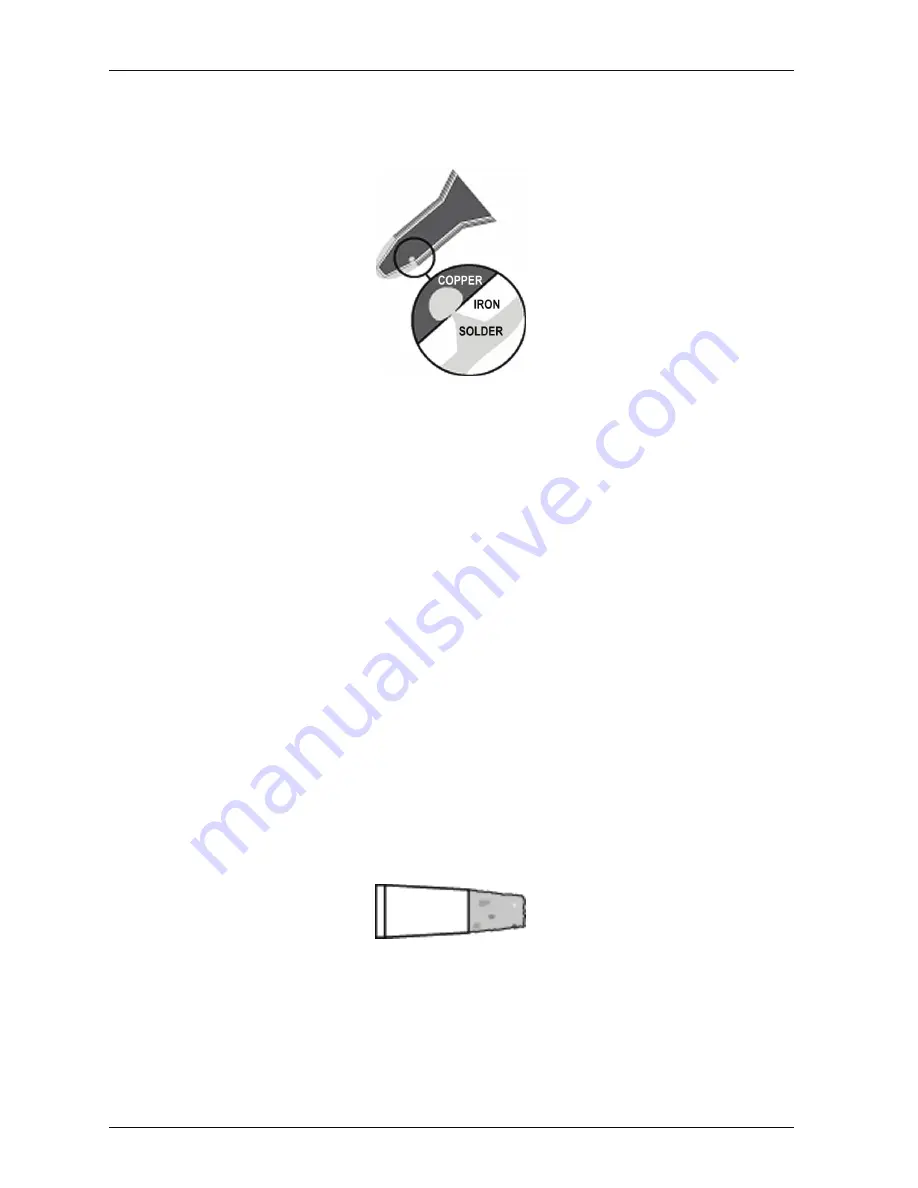

When a crack opens in the iron plating due to abuse or corrosion, solder comes in contact with the

copper core, forming an intermetallic compound. This flaw propagates through the tip, quickly leading to

failure and breakage.

Wear

•

Select the largest tip possible for the lead being soldered. Blunter tips carry more plating.

•

Do not apply excessive pressure during soldering.

•

Do not “scrub” the lead. To maximize heat transfer, tin the tip and create a solder bridge.

•

Do not drag solder. If you must drag solder, use a specialty SMT tip.

•

Do not use commercial tip tinners for routine tinning. Use a flux core solder wire or paste.

•

Use a clean, wet sponge to clean the tip. Do not use a dry sponge, rag, or any abrasive.

Corrosion

•

Select lower activity fluxes where possible. RMA flux is best for maximum tip life.

•

Use only sulfur free sponges for cleaning tips.

•

Use only clean sponges. Discard dirty sponges.

•

Use de-ionized, purified water to dampen sponges.

•

Use RMA solder to tin tips during storage. If possible, avoid aqueous or high activity flux

solders.

To Minimize Corrosion:

1. CLEAN the tip with a damp sponge.

2. TIN the tip with solder.

3. TURN OFF the power supply when not in use.

In the illustration below, corrosion attacks the tip, leading eventually to dewettting or plating failure.