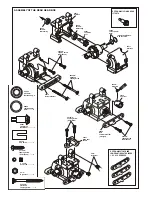

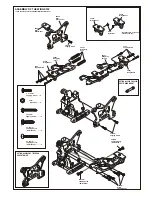

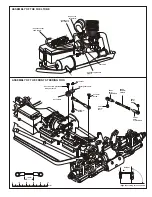

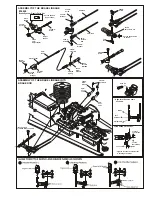

3 X 8mm

Washer

3mm Nylon

Locknut

3 x 5mm Screw

3 x 20mm

Cap Screw

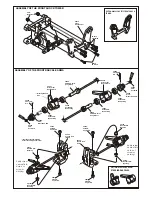

* Place the clutch shoes

with the clutch springs

over the 3 pins of the

flywheel.

Using a screw driver as a lever,

bend the small end of the

clutch spring behind the

clutch nut and press

down to snap shoe in

place.

* Tighten the flywheel using a

cross wrench or deep socket.

If engine turns when tightening,

hold piston with large thick tie-wraps

and hard wood in exhaust port.

Do not use metal, it will

damage engine.

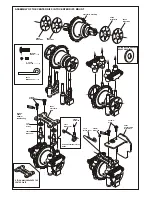

#10098

SG Nut & Shim KiT

#10098

SG Nut & Shim KiT

Engines with ground shafts and few threads

are called SG Shaft. A special clutch nut is needed.

The stock flywheel (#10040) is fine.

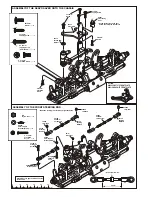

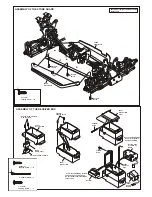

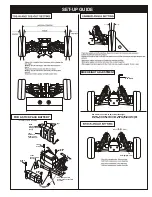

ASSEMBLY OF THE CLUTCH INTO ENGINE

#10100

Clutch Spring

#10010

Clutch Shoes

Black Type

* Shoes are

trailing.

3 x 8mm

Washer

Misc. Hardware

#10099

#34110

5x10x4mm

Ball Bearing

#34110

5x10x4mm

Ball Bearing

#10040 (stock)

3 Pin

Flywheel, Taper

#10091

Clutch Nut

screw type

3 x 5mm

Screw

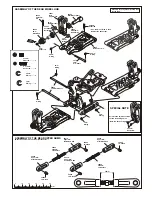

#10330

Brass, Corn (big hole)

#10329

Brass, Corn (sml hole)

3mm

Nylon Lock

Nut

3mm

Nylon Lock

Nut

3 x 20mm

Hex Screw

3 x 20mm

Hex Screw

#30480

Engine Mount

#30481

Screws set,

Engine Mount

#30481

Screws set,

Engine Mount

#10398 - 12T

#10399 - 13T

#10400 - 14T (stock)

#10401 - 15T

#10402 - 16T

#10403 - 17T

#10404 - 18T

Clutch Bells

SEE NOTES ABOVE

Notes:

Threaded Shaft Engines

Non-Pull Start Engines...

• Alum. Washer behind the flywheel is not needed when using Force engines or similar types. O.S. Engines will

require washer space #10048 or #10049 shim kit. This requirement old and may not be needed for current engine

production. To check!..place the brass corn #10330 (big hole) against the engine bearing, then flywheel. You

should be covering one or two thread of the engine shaft. If this is the case, you do not need an additional washer

behind the flywheel.

• You must cut the engine shaft if too long. Count 6 threads in front of the flywheel and mark. This is all you need

to tighten the clutch nut and mount the flywheel.

Force Pull Start Engine...

• Force .21 Pull Start Engines required NO additional spacer and no shaft cutting. The Force engines comes with

an alum. cast driver washer, you use this part as the spacer, not the alum. washer shown for O.S. installs

But, you must find the #10329 brass corn (sml hole) for Flywheel. This special corn fits the smaller thread

diameter of the engine shaft. It will center the flywheel when tightening the clutch nut.

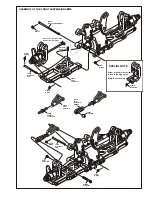

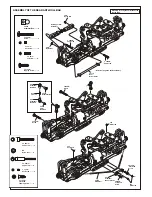

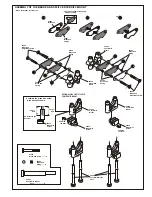

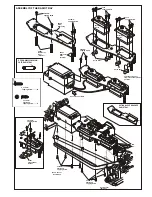

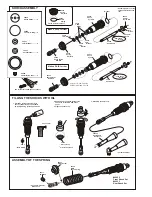

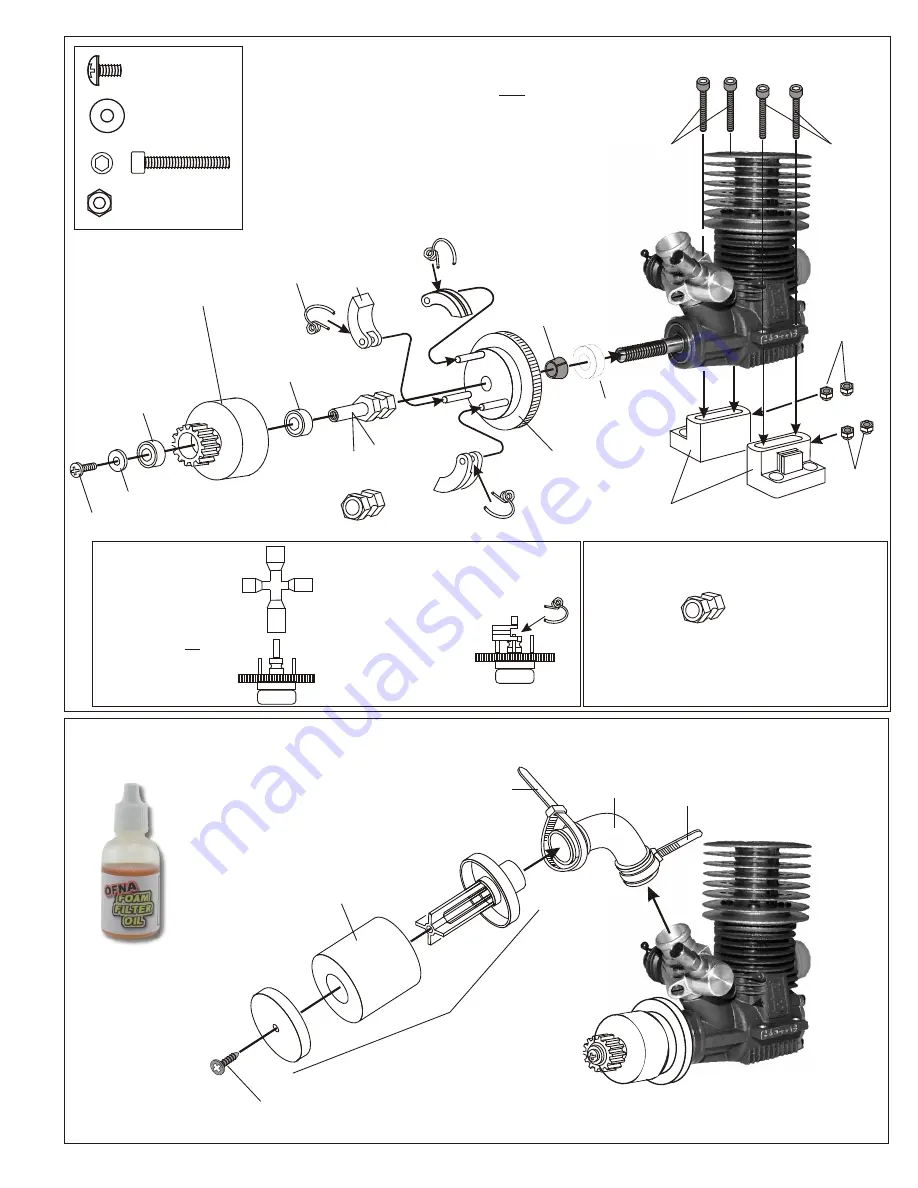

3 x 10mm

Tapping Screw

#10016

Air Filter

Sponge

Refills

#10017 - Blue

#10018 - Yellow

#10019 - Rose

#10035 - CNC Alum.

Foam Filter, Blue

Foam Air filters Unit

#10021 - Black

#10027 - Yellow

#10028 - Pink

#10029 - Blue

Air Filter Connector

Nylon Strap

( Small )

Nylon Strap

( Small )

ASSEMBLY OF THE AIR FILTER

You must oil foam filter before use.

Filter will not work if not oiled.

Clean with soap and water only.

You will damage foam if washed

if fuel!

#10015, Foam

Filter oil, $2.95

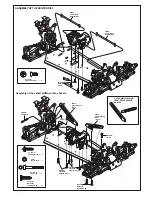

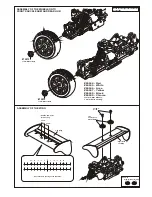

1114

3mm Hex Screw

for Engine Mount

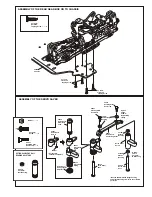

40047

Fuel Tank

Post

( Front )

40047

Fuel Tank

Post

( Rear )

* Take the fuel tank post

from J-42 plastic parts tree.

3x3mm

Set Screw

40050

Muffler Stay

Post

40051

Muffler

Stay

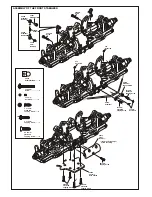

INSTALLATION OF THE FUEL TANK

AND ENGINE ONTO CHASSIS

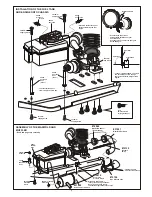

3X15mm

Tapping Screw

3X15mm

Tapping Screw

40066

Pressure

Nipple

40066

Fuel Tank

40066

Fuel Nipple

3x10mm

Tapping Screw

3x10mm

Tapping Screw

ASSEMBLY OF THE MANIFOLD AND

MUFFLER

* Read this page very carefully.

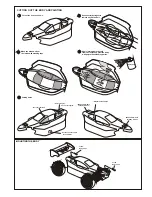

4x10mm

Flat Head

Screw

5x5mm or 4x4mm

Set Screw

* Tighten the strip

and cut off the excess.

* Drill a hole (Size 3.5mm)

in the place and align as shown.

Use a two part epoxy glue to

full seal the nipple base to the nipple.

3x20mm

Cap Screw

Note Book Paper

* Use note book paper to set

gear backlash between spur gear

and clutch bell.

If the space is not correct the spur gear

will be damaged.

Spur Gear

Clutch Bell

90 Degree

* Loose or tighten 3x20mm cap screw

and 5x10mm hex screw to align

spur gear and clutch bell gear to 90

degree.

* Assemble the fuel tank post

before assembling the fuel

nipple.

#10069

Manifold Adapter

( Red Silicone )

#31991

Manifold, Polished

#10120

Manifold

Spring

#10184

Blue,

Silicone Tube

#10079

Alum. CNC

Pressure Nipple

#31992

Dual Chamber, Polished

Because SG engines are more

common. Some kit include an

SG nut, please look to see if

your has this item. If not you

can purchase one from your

local dealer.