25

Graphic LCD display

1.0

4

Description and design

of the main display

4.1

All important data of controller operation are shown on the graphic LCD display.

Display of information on the screen:

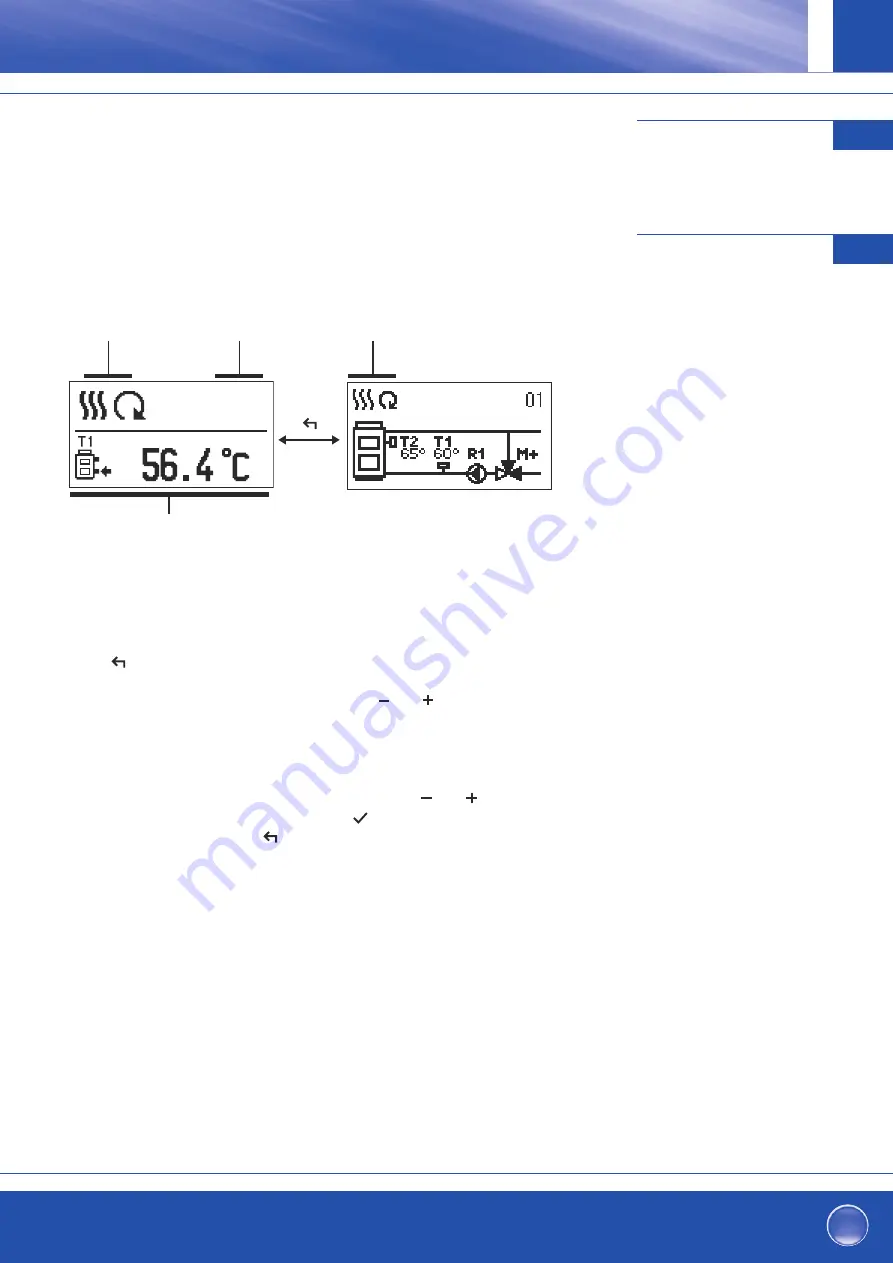

The controller mode, notifications and warnings are displayed in the upper third of the

display. For switching between basic display and display of the hydraulic scheme use the

button .

To check the temperature and other data, use buttons and . The number of sensors

and other data, which can be listed on the display, depends on the selected hydraulic

scheme and controller settings.

Note: If you would like to have a specific data display to appear after you stop using

the keyboard then select the desired data with buttons and . Confirm

the selected screen by pressing the button for 2 seconds.

Note: When you press the button for 2 seconds, then the display of the temperature

will change from one to two rows and vice versa. On the two line

temperature display, the measured temperature is displayed in the first row

and the required or calculated temperatire in the second row.

Controller mode.

Controller mode.

Temperature, protection functions and

overview of other data.

Notifications

and warnings.

Constant temperature controller

GB