Mounting instructions PYROLINE

®

Rapid fire protection duct

EN | 29

Direct mounting on the ceiling, wall or floor

5 5

Creating a wall/ceiling penetration

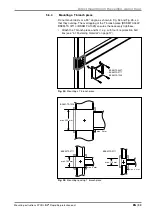

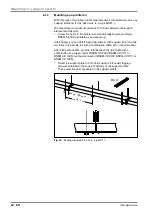

With wall or ceiling penetrations, for the achievement of the fire resistance

class I30–I90, it is sufficient to plug the cavities around the duct with min-

eral wool and seal them with filler (see Fig. 28 and Fig. 29).

However, if I120 is to be achieved, then seal both sides of the penetration

with a wall connection fitting BSKM-WA 0711 or BSKM-WA 1025 (see

“5.6.6 Mounting a reducer” on page 36). The wall connection fitting is

only available for BSKM 0711 and BSKM 1025.

The wall penetration can be created in a solid wall or a dry construction

wall (lightweight construction wall). When the wall connection fitting is

used, the ducts must run to the wall or ceiling at a 90° angle.

If there is a fire, to prevent heat transfer within the wall inside a duct to the

connection duct, the wall may not be penetrated with a single duct piece.

Instead, the ducts must be mounted separately within the wall with a gap

width of 5‒10 mm.

The two following examples show the mounting of wall penetrations. The

ceiling penetration is mounted in essentially the same way.

5 5 1

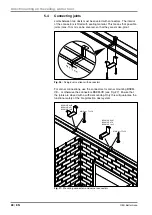

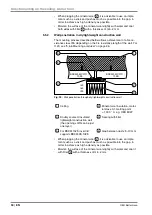

Wall penetration in solid wall

The mounting process described below allows achievement of a fire re-

sistance class I90, depending on the fire resistance length of the wall. For

I 120, see “5.6.6 Mounting a reducer” on page 36.

5-10 mm

BSKM 0407/0711/

1025

I30

I60

I90

BSKM 0407/0711/

1025

1

5

6

4

2

3

Fig 28:

Wall penetration through solid wall

1

Ceiling

2

Mineral wool insulation, mater-

ial class A 1, melting point

> 1,000 °C, e.g. OBO MIW

3

Solid wall

4

Sealing with filler

5

For BSKM 1025: insert lid

supports BSKM-DS 1025

6

Gap between ducts: 5‒10 mm