JUMBO 7000 HFK SCISSOR

Nussbaum Automotive Solutions, LP | 1932 Jordache Court, Gastonia, NC 28052 | 704.864.2470 | Email:

22

11.3.

MOUNTING THE PLATFORM, CONTROL STATION AND HOSE COVERS

•

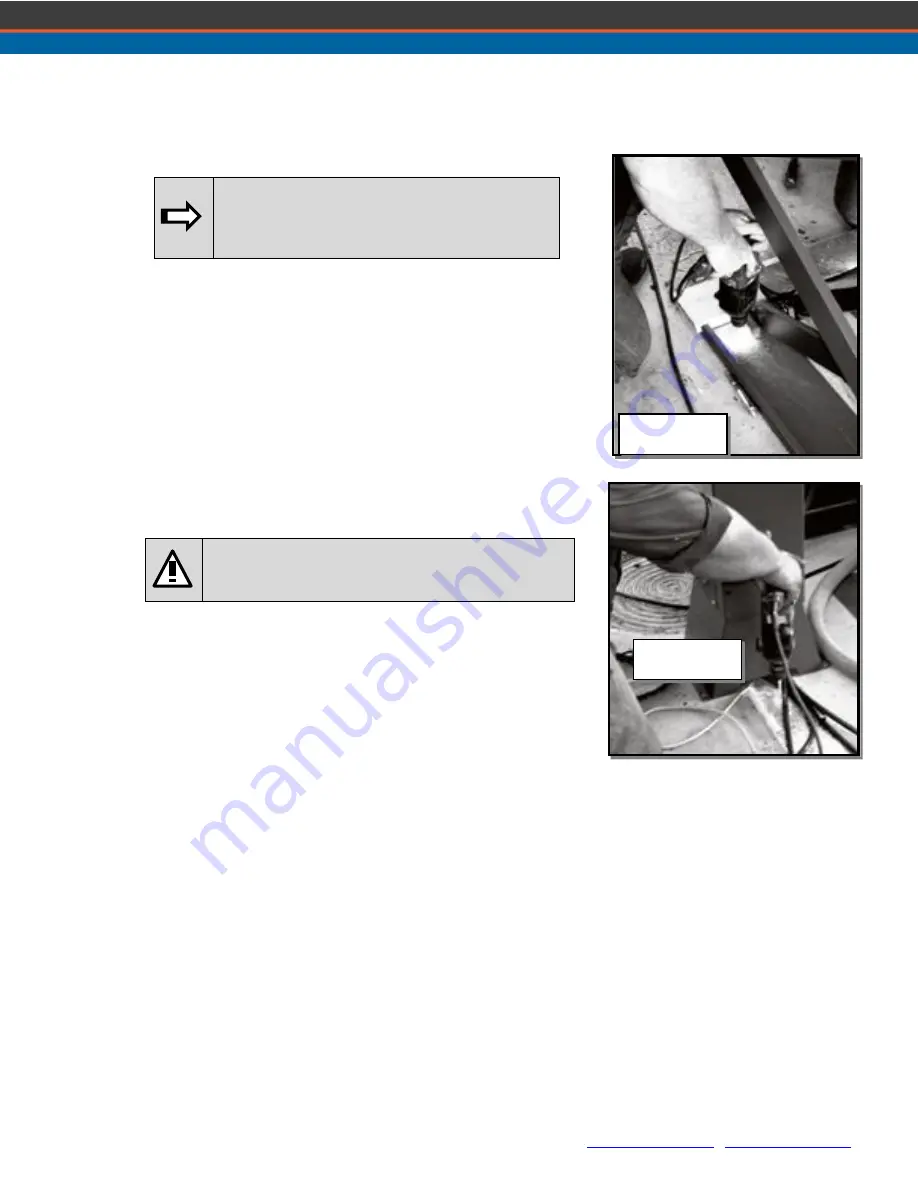

Drill

½” (

12mm) mounting holes through their corresponding locations in the four corners and centers of each

platform. To ensure the platforms do not move during the drilling process, insert an anchor after each hold is

drilled. Make sure to clean all debris from holes before inserting anchors. (Fig. 15)

•

Lower the lift (moving an obstruction first) and straighten the hydraulic

hoses in the bottom covers making absolutely certain they are not

kinked, smashed or accidentally nicked during the drilling process. The

“T” fittings can be slightly loosened during this process to help flatten

the hoses in the cover.

•

Making sure the left and right hose covers are straight, drill ¼” (6mm)

holes into concrete through the corresponding locations in the cover

bottoms. Insert anchors as the holes are drilled to prevent any potential

movement.

•

Locate the final position for the control station. If the hose cover is too

long, it should be cut to length with a hacksaw. It should protrude

approximately ½” (12mm) under the control station.

Any sharp edges on the cover bottom or top must

be eliminated to prevent accidentally cutting one

or more of the hydraulic hoses

•

Position the final hose cover bottom and drill ¼” (6mm) holes through

corresponding locations. Insert anchors as the holes are drilled to

prevent any potential movement. (Fig. 16)

•

Position the control station in its final location and drill ¼” (6mm) holes

through corresponding locations in the base (Fig. 17). Insert anchors as

the holes are drilled to prevent any potential movement.

•

Cycle lift through several up/down cycles observing all hydraulic hoses and fittings for leaks. If leaks are

present, tighten fittings to eliminate. If leaks are still present, contact Nussbaum Technical Service.

•

If no leaks are present install top hose covers on bottom hose cover plates

(Fig. 18) and tighten nuts on anchors. Anchors protruding out from the nut should be cut off flush.

Drill the holes completely through concrete if

possible. This will allow the anchors to be flush

with the concrete and filled if the lift is ever

moved to a new location

Figure 15

Figure 16