6

08. 10. 20. Document Number 670506

Nuaire |

Western Industrial Estate

|

Caerphilly

|

CF83 1NA

|

nuaire.co.uk

TRA / TRC / TRM

Installation Manual

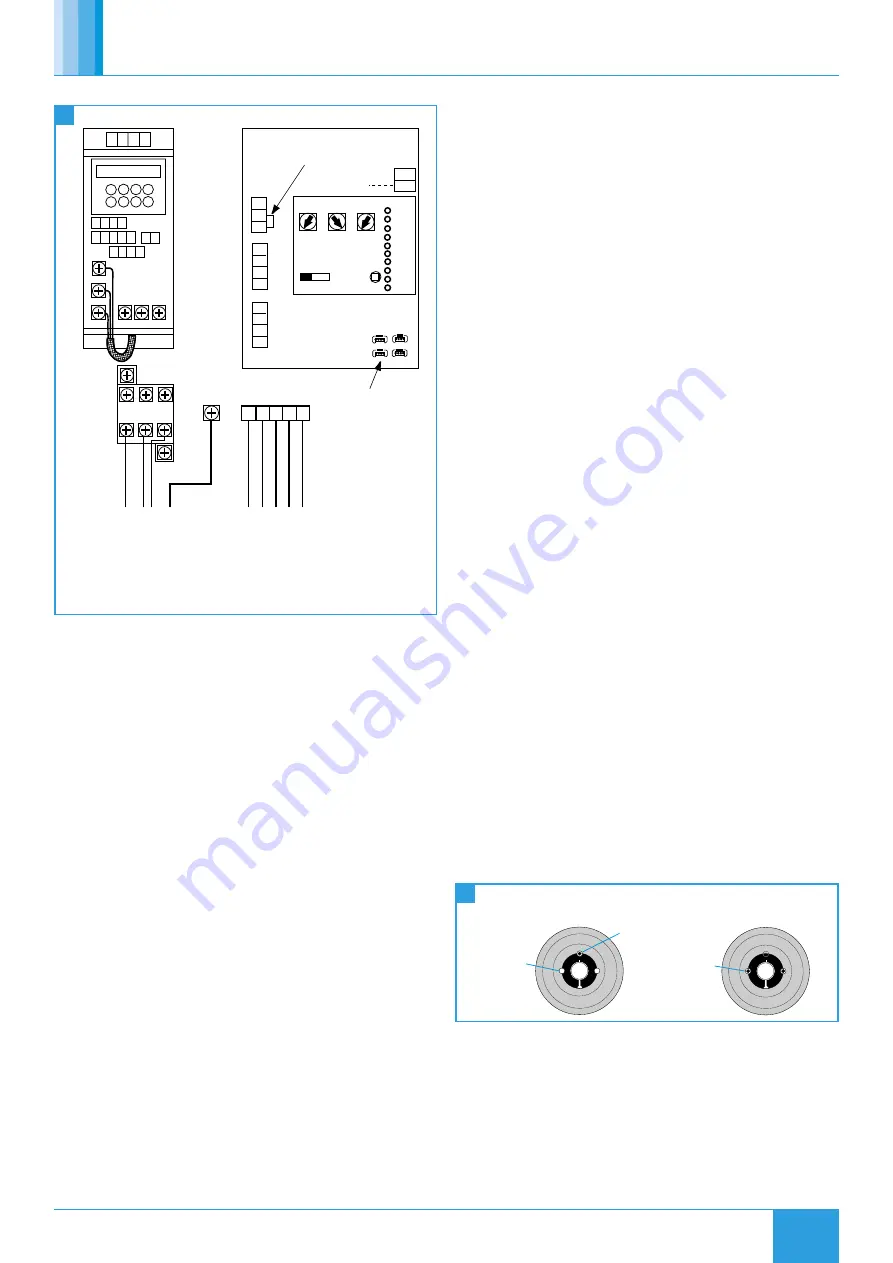

4.3.5 Three Phase, Ecosmart Speed Control

N

L

SL

Max SL run on

Min

Trickle

Test

0 1

Pwr

Standby

Fan 1

Heating

Cooling

Fan 2

Fault

Tx

Rx

Frost

Ecosmart

Earth

D

AMPER

L3

L1

N

E

FA

ULT

RUN

L2

Mains supply connections

400V 50Hz 3ph + Neutral

via local isolator

3 5

1

4 6

2

(U)

(V) (W)

L3

L1 L2

E

(U)

(V) ( W)

L3

L2

L1

12 13

15

14

5

9

6 7 8

10 11

2

1

3 4

A1

A2

CON

TA

CTER

0V

0-10V

BMS signal

'NET' connection

E N L1 L2 L3

U V W E

DP

CL

N

RET

Connections to fan via screened

power cable. Purpose made glands

are provided to earth the screening

Remove this link if:

1: A switched live signal is connected

2: A ES-PIR, ES-TC or BMS Signal is connected

Note: Internal connections

between the supply

terminals, output

contactors the PCB and

inverter are made at

the factory

Note: The Ecosmart control box is a seperate item packed

individually. See installation document 671193 for details

of Ecosmart Control (ES-ISC).

11

Three Phase, Single Speed (TRA100H-43 Only) Wiring Diagram

5.0 MAINTENANCE

It is important that maintenance checks are recorded and that the

schedule is always adhered to, in all cases, the previous report should

be referred to.

Before attempting to carry out any work; ensure the unit and speed

control, if fitted, are electrically isolated.

Do not operate the unit with the cowl removed. The impeller will

continue to rotate after the supply has been disconnected - allow

sufficient time for the impeller to come to rest.

Remove the cowl to gain access to the moving parts.

The unit is not

weather tight when cowl is removed.

TRA (Axial)

The impeller is accessible immediately and can be removed

if required.

TRC (Centrifugal)

Motor/impeller bridge assembly can be removed

after releasing the 4 or 6 screws holding the bridge support. On this

unit the impeller cannot be removed from the motor.

TRM (Mixed flow)

Motor/impeller bridge assembly can be removed

after releasing the 4 or 6 screws holding the bridge support. Invert the

bridge and remove impeller if required

5.1 Routine Maintenance

•

Generally clean all areas of unit and treat any areas of corrosion.

•

Check the impeller rotates freely and does not foul the fan plate.

•

Remove all dust and dirt from impellers, be especially careful not

to disturb balance weights.

•

Check that bird guards (if fitted) / safety grilles are secure and free

of obstruction.

•

Check anti-backdraught shutters operate correctly.

•

Inspect the condition and tightness of all fittings.

5.2 Annually

•

Thoroughly inspect the unit and its components for corrosion,

acting immediately to treat/restore any damaged areas.

•

Check motor for undue wear, signs of overheating and apply

winding insulation and continuity tests

•

Inspect all bolts, fixings and electrical terminals for security.

•

Check resilient mounts and replace any that show signs of wear or

deterioration.

5.3 Impeller Cleaning

A build-up of dust/dirt may be removed by brushing carefully with a

stiff brush. Take care not to damage or distort the impeller blades. If the

impeller is too badly fouled to allow cleaning in situ, proceed as follows:

•

Remove the impeller.

•

Remove all loose dirt using a stiff brush.

•

Sponge the impeller with warm soapy water.

Do not use solvents

or caustic fluids.

•

Rinse thoroughly with clean water and wipe dry.

5.4 Impeller Removal

5.4.1 TRA (Axial)

•

Knock up the tab washer and remove the retaining screw.

•

Remove the impeller from the motor shaft.

•

Retain the motor shaft key.

•

Replacement is the reversal of the above procedure.

5.4.2 TRC (Centrifugal)

On this type of unit the impeller cannot be removed from the motor.

Cleaning of the impeller must be carried out in situ.

5.4.3 TRM (Mixed Flow)

On this type of unit the impeller is held in place by a taper lock fixing.

To release the impeller:

•

Remove the grub screws on each side of the slit.

•

Lightly lubricate one of the grub screws and insert it into the

threaded hole opposite the slit (A).

•

Carefully tighten the grub screw until the tapers ‘break’ allowing

removal of the impeller.

•

Remove the impeller.

12

Mixed Flow Impeller Taper Lock Details

A

1. Remove both

grub screws

2. Insert grub

screw and tighten

Fit both grub

screws and

tighten

B

5.5 Impeller Replacement (TRM Only)

Place the impeller over the shaft and locate the taper lock in the

impeller. Insert and tighten the two grub screws into the tapped holes

either side of the slit (B).