2

Remove the unit cover, retained by two M4 screws (see fig 3).

Pull out the electronic control module approx. 15mm to disengage

the electrical spade contacts (see figure 5).

Note the unit control module speed adjustment on the control

module (figure 7) must be set at 25% for low (NORMAL)

speed.

The standard setting as supplied from the factory for high BOOST

speed is 100% and will give the optimum performance for most

applications. See ‘Adjusting the NORMAL and BOOST speeds’.

Unscrew the four, M5 x 35 captive blower retaining screws.

Remove the blower assembly complete with the electronic control

module (see figure 6).

Mark the four main unit fixing positions on the mounting surface.

Drill and plug the surface to accept the unit fixings (the fixing

centres are shown in figure 6).

NOTE: For wall mounting ensure that the cable access is on

the left (as shown in the drawing).

Select a suitable location for the remote switch supplied. Prepare

the mounting surface to accept the standard MK switch box and

arrange the box in position. Wire the switch to the fan terminals

3 and 1 (these are low voltage terminals).

Offer the unit up to the surface and bring the mains wiring and

remote switch wiring through the cable entry grommet provided

in the back of the unit casing.

Connect the ductwork to the outlet spigot and fix the unit to the

surface. Any subsidiary inlet ductwork can now be connected to

the unit.

Fitting a subsidiary

inlet spigot

The subsidiary inlet spigots

supplied will replace any of

the four standard unit inlets.

(See Figure 1).

Select the inlet position required.

With the front cover removed,

press out the standard inlet

grille. Locate the inlet spigot

supplied into the aperture and

press into position.

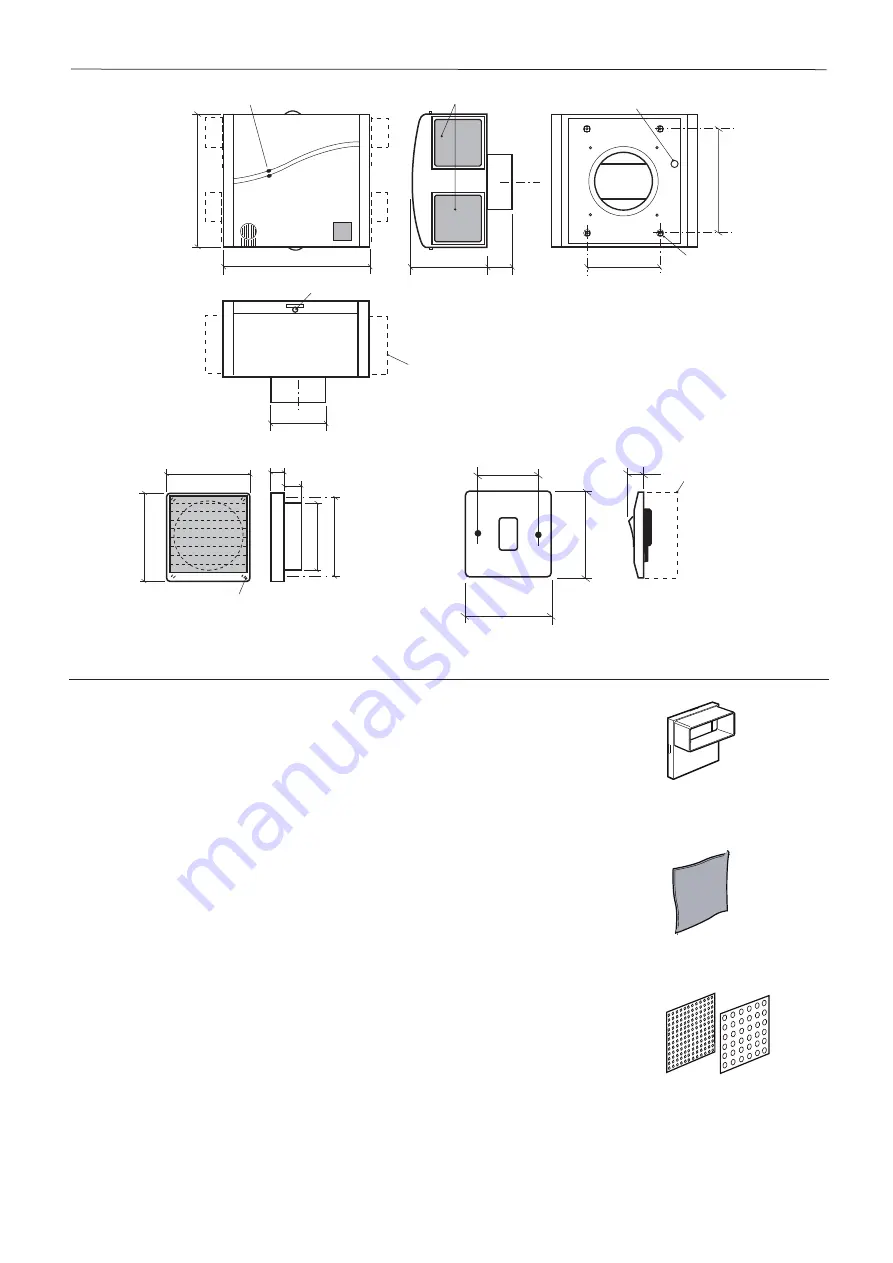

Dimensions

Figure 3.

Installation and Maintenance

MEV-B Continuous Mechanical Extract Ventilation Units

24. 06. 13. Leaflet Number 671078

FILTERS (4 supplied)

Note: suitable for remote inlet

grilles or fan unit inlet grille

T1

T2

BALANCING PLATES

(4 x T1 and 4 x T2 supplied)

Note: can be used under any

inlet spigot filter

SUBSIDIARY INLET SPIGOT

(Two supplied) To suit

110 x 60mm rectangular ducting

(not supplied)

335

125 dia

160

50

160 ctrs

2

48 ctrs

320

LED Run & Fail

indicators

Inlets (both sides)

shown with filters fitted

Cable

access

Fixing

points

REAR VIEW

END VIEW

Cover fixing

screws

Optional positions for

additional subsidiary spigots

(supplied)

125

125

13.5

15

11

0 fix ctrs

99 O.D.

4 x 3.7mm dia fix holes

on 110 mm fixing ctrs

INLET GRILLE Code: 100 IG (4 supplied)

Note: Drawing shows grille fitted

with its matching filter

NORMAL

BOOST

85

85

15

REMOTE SWITCH

(Not supplied Part No. 773532)

For additional switches see 'Spares' on page 5

Standard MK

switchbox

2 x 4mm dia

holes 60mm

centres