Installation, Operating and Maintenance Instructions

SQURBO XBOX

1.0

General

The information contained in this document gives details of

operation and maintenance for installers and users of Nuaire

SQURBO XBOX equipment.

These air handling units comprise a combination of modular

sections assembled (at works or on site) to suit the application

requirements as specified by the purchaser.

General information regarding performance and specifications for

the equipment may be obtained from our Technical Literature, and /

or project specific documentation.

2.0 Delivery of Equipment

2.1 Receipt of equipment

All equipment is inspected prior to despatch and leaves the factory

in good condition. Upon receipt of the equipment an inspection

should be made and any damage indicated on the delivery note.

Particulars of damage and/or incomplete delivery should be

endorsed by the driver delivering the goods before offloading by

the purchaser.

No responsibility will be accepted for damage sustained during the

offloading from the vehicle or on the site thereafter.

All claims for damage and/or incomplete delivery must be reported

to Nuaire within two days of receipt of the equipment.

2.2 Offloading and Handling from the

delivery Vehicle

The weight of the unit modules and palletised items is displayed on

the unit rating plate or on the packaging. Some of the modules

have an uneven weight distribution, and this will be indicated by

labelling where appropriate. Ensure that lifting and handling

equipment is adequately rated.

Offloading and positioning of the equipment is the responsibility of

the purchaser.

Spreaders should be used when lifting with slings to avoid damage

to the casings. Care must be taken to ensure that slings are

correctly positioned to avoid crushing and twisting of the unit

castings.

Where channels and/or support frames are bolted to the underside

of the unit casing, slings or fork-lift arms should be positioned to

locate in the apertures in the channels. If Lifting Eyes have been

supplied / fitted it is recommended that they are used.

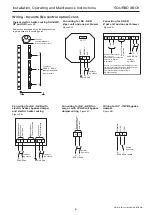

Figure 7: Lifting.

2.3 Storage

The equipment must be stored in a dry, internal location. Ductwork

connection apertures shall be sealed against the ingress of dust,

water and vermin.

Note that units that are intended for external locations are generally

not fully weatherproof until their installation, including ductwork

connections is complete.

If the storage period is to exceed two months, contact Nuaire for

guidance on the appropriate “mothballing” procedures. Do not

stack units, modules or components.

3.0 Erection and Assembly

Units must be installed in accordance with good industry practice,

upright and level on a prepared base (which may include a suitably

designed suspended platform).

Support positions should be determined to provide a distributed

support for the unit base, and should not obstruct access panels

or air way connections.

Heat recovery modules and modules that incorporate cooling coils

may produce condensation during use. An insulated drip tray and

drain connection is provided, and should be connected to a suitable

drainage point.

(*Note that provision of a powered condensate

pump is an option for this type of equipment. If such a pump is

supplied, the main drip tray drainage point should be capped,

and the pump discharge tube routed as required. Specific

instructions for the pump type fitted will be attached to the

unit.)

Provision may be required, and if so, should be made, for the fitting

of a correctly sized cleanable trap to each drain connection.

Figure 8: Condenste trap.

If the condensate tray is located at the inlet side of the fan (i.e.

under negative pressure) then calculate the values of

A & B as shown below. (and see fig. 5).

A = Fan inlet pressure (mm H2O) +25mm (minimum).

Allow 100mm for these units if pressure is unknown.

B = A/2. (minimum).

(Note: 10Pa = 1mm H2O).

If the condensate tray is located at the outlet side of the fan (i.e.

under positive pressure) then calculate the values of A & B as

shown below.

A = 25mm (minimum).

B = Fan outlet pressure (mm H2O) + 25mm (minimum).

Allow 100mm for these units if pressure is unknown.

The installation, including all external services and controls should

be installed in accordance with the appropriate authority and

MUST conform to all governing regulations e.g. CDM,CIBSE, IEE,

and in strict accordance with the applicable Building Regulations.

2

Assembly with base frame.

Palletised.

Forklift.

Slings via spreaders fitted to unit with

base frame.

Safety first! –before commencing any work ensure:

•

That all appropriate risk assesments have been carried

out, and the required safety measures have been taken

•

That you understand the work required

•

That you are trained and competent to carry it out

08. 06. 18. Leaflet Number 671408

Hand tight plug

B

A

From

condensate

drain pan

Hand tight plug

Connect to

ventilated

downpipe

to drain