The dampers must be installed indoors, away from

sources of heat, steam or water spray.

Operating ambient: 5-40

o

C, up to 95%RH (non condensing).

This unit must be earthed.

Do not distort the casing as this will cause the

moving part to jam.

Please note the dampers’ orientation is indicated

by the arrow. This must correspond to the direction of

the airflow when installing the damper.

5.0 Installation

The installation must be carried out by competent personnel in

accordance with the appropriate authority and conforming to all

statutory and governing regulations.

The CVD damper must be located in an accessible location for

service and maintenance as prescribed in the CDM regulation.

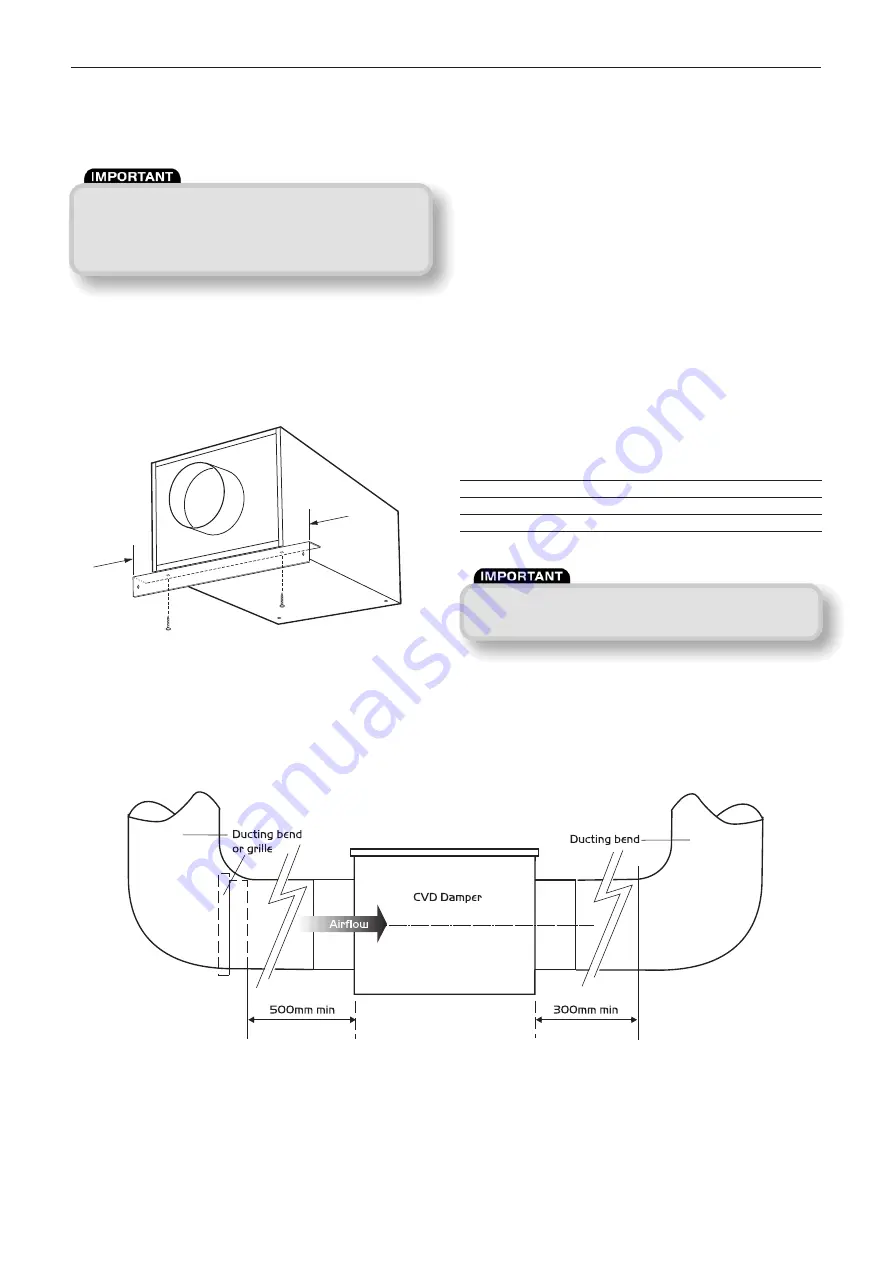

If the rigid ducting at the inlet and outlet of the damper are securely

fixed to their support; the damper may be coupled directly to the

ducting without additional fixing. If this is not the case; secure the

damper to a rigid, vibration-free surface using the brackets suppled

(see fig 5).

Figure 5.

Remove the screws from the underside of the unit and use these

to attach the fixing brackets.

5.1 Installation practices to obtain the

best result from the CVD damper

(see figure 6).

1.

Always fit at least 500mm of straight RIGID ducting at the

damper inlet before connecting to any bends, grilles or

obstructions (see figure 6).

2. Similarly always fit at least 300mm of straight RIGID

ducting at the damper outlet.

3. Do not fit balancing damper or other devices that creates

a jet within 10m upstream of the inlet to the CVD damper.

4. Avoid multiple bends near the inlet side of the CVD damper.

5. Avoid the use of flexible ducting; do NOT fit flexible ducting

directly on to the CVD damper. See items 1 and 2.

6. Air valves with screw-in adjustments should be set up with

maximum opening.

Failure to meet these conditions means the damper’s calibration

may be affected and would require careful commissioning to

produce the desired flowrate.

See commissioning guide on page 4.

Typical accuracy of the dampers under ideal conditions are:

Unit

Typical Accuracy

CDV 125

+ or - 3 l/s

CDV 150

+ or - 3 l/s

CDV 200

+ or - 4 l/s

Installation and Maintenance

CVD Constant Volume Dampers

Figure 6. Installation practices to obtain the best result from the CVD damper.

(Also see 5.2 Top installation tips on page 3).

2

10. 05. 17. Leaflet Number 671638

50

50