NSS ® Enterprises, Inc.

3115 Frenchmens Road, Toledo, Ohio 43607

PHONE (419) 531-2121 FAX (419) 531-3761

NSS ® Enterprises, Inc. European Distribution Centre

Unit II, Pinfold Trading Estate * 55 Nottingham Road

STAPLEFORD, NOTTINGHAM NG9 8AD ENGLAND U.K.

PHONE: (44) 0115 939 1568 * FAX: (44) 0115 949 0615

WRANGLER 20 E ORIG. 08-95 REV. B 07-99 9092316 WHW

TROUBLE SHOOTING

PROBLEM

CAUSE

SOLUTION

No Solution Flow

The solution valve is closed.

Open the solution valve.

Obstruction in the solution hose.

Remove the obstruction.

Solution valve or linkage damaged.

Repair/replace the valve linkage.

Solution tank is empty.

Fill the tank.

Solution Flow Does Not Stop

The solution valve is open

Close the solution valve.

Solution valve or linkage damage.

Repair/replace the valve linkage.

Solution valve is dirty.

Clean the solution valve.

Damaged seat and washer in valve.

Replace valve.

The valve stem is dirty.

Clean and lubricate valve stem.

Will Not Pick Up Any Water

Squeegee is up.

Lower squeegee.

From Floor

Vac motor switch is “off”.

Turn vac motor switch “on”.

Recovery tank is full.

Empty tank.

Vacuum shut-off float is stuck.

Open float valve/remove obstruction.

Obstruction/damage in the squeegee,

Remove obstruction/repair damage.

squeegee hose or standpipe.

Leaking cover gasket.

Remove old gasket/replace.

Vac motor is not running

Have an authorized serviceman Repair.

Will Not Pick Up All Water

Squeegee blade is worn/damaged.

Reverse/replace squeegee blade.

From Floor

Obstruction/damage in the squeegee,

Remove obstruction/repair damage.

squeegee hose or standpipe.

Squeegee pressure needs adjustment.

Adjust pressure.

Vacuum motor worn out.

Repair/replace vac motor.

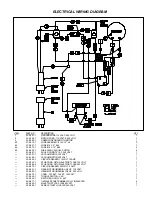

Batteries Do Not Seem To Run Tops of batteries are dirty/wet

Clean/dry charge batteries.

Long Enough

Battery terminals are dirty/damaged.

Clean terminals and connectors,

replace damaged cables. Charge.

Electrolyte level is too low.

Add distilled water and charge.

Batteries are not fully charged.

Charge batteries for 8 hours.

Charger is damaged.

Have an authorized serviceman repair.

Battery is defective.

Check cell voltage while discharging.

Cleaning Is Not Even

Brush/pads are worn.

Replace.

Damage to brush assembly, casters, or

Have authorized serviceman repair.

solution valve.

Motor is not running.

Repair wiring, replace switch, replace

carbon brushes. Reset circuit

breaker button.

NOTE: If problems remain after taking the above steps, contact your local

authorized service station for further evaluation and repair.

Summary of Contents for WRANGLER 20 E

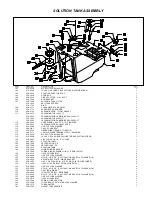

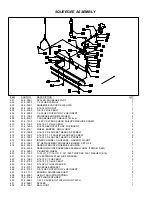

Page 5: ...WHEEL AND VALVE ASSEMBLY...

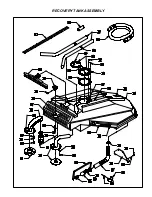

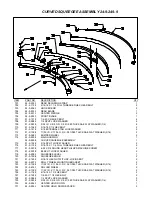

Page 7: ...RECOVERY TANK ASSEMBLY...

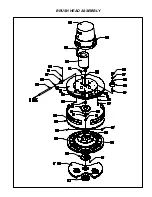

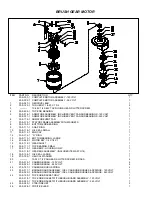

Page 11: ...BRUSH HEAD ASSEMBLY...