SET-UP:

Fill the holding tank with clear water and add the detergent of your choice. Mix well. Plug in the

electrical cord and turn on the pump and vacuum switches. You are now ready to begin cleaning.

PUMP OPERATION:

The 100 PSI-pump is a "demand" type design. The pump runs only when you depress the lever

on your wand. When you release the lever the pump shuts off.

VACUUM OPERATION:

A switch is provided for each vacuum motor. The machine can operate on either one or two vac

motors. A patented vacuum manifold reduces the oscillations between the two vacuum motors in

series, thereby increasing the efficiency and life of the vacuum motors.

BALL FLOAT VAC SHUTOFF:

When the recovery tank is full, the float system will shut off the incoming air flow and prevent

water from entering the vacuum motors. The float may not work properly if the float filter is

clogged or if there is heavy foam in the tank.

CAUTION: To avoid vac motor damage, always make sure the float filter is clean and the ball

travels freely before turning on the machine. Use a defoamer whenever foam is present.

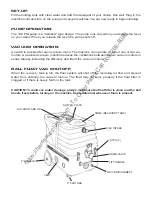

DOME (RECOVERY TANK)

VAC INTAKE

DRAIN VALVE

LIFT HANDLE

QUICK-DISCONNECT

LATCH (2)

3" CASTORS

8" WHEELS

HOLDING TANK LID

VENT

SWITCH PLATE

https://harrissupplyind.com - To Order Parts Call 608-268-8080