N1540

NOVUS AUTOMATION

2

difk

Alarm of the maximum differential value. It triggers when

the PV value is

above

the point defined by:

ALrF+SPA1

(using alarm 1 as an example).

ALrF

PV

ALrF + SPA1

ALrF

PV

ALrF + SPA1

SPA1 positive

SPA1 negative

ierr

Sensor breaks alarm. It is activated when the Input

presents problems such as interrupted sensor, bad

connection, etc.

Table 2 –

Alarm functions

Note

: The figures are also valid for Alarm 2 (SPA2).

Important note:

Alarms configured with the

ki

,

dif

and

dif.k

functions also trigger their associated output when a sensor fault is

identified and signaled by the digital panel meter. A relay output, for

example, configured to act as a High Alarm (

ki

), will operate when

the SPAL value is exceeded and when the sensor connected to the

input is broken.

ALARM BLOCKING INITIAL

The

Initial

Blocking

option inhibits the alarm from being recognized

if an alarm condition is present in the process when the digital panel

meter is first energized. The alarm will be enabled only after the

occurrence of no alarm condition.

The initial blocking is useful, for example, when one of the alarms is

set up as a minimum value alarm, which may cause the activation of

the alarm soon upon the process start-up; an occurrence that may be

undesirable in many cases.

The initial blocking is not valid for the

ierr

(Sensor Break) function.

OFFSET

Allows fine adjustments to the PV indication, correcting measurement

errors that appear, for example, after the replacement of the

temperature sensor.

MAXIMUM AND MINIMUM

The digital panel meter memorizes the measured maximum and

minimum values (peak and valley). The operator can observe these

extreme values at any time. These two values are shown when

pressing the

F1

(maximum) and

F2

(minimum) keys. Pressing both

keys simultaneously will clear the memory for a new peak and valley

detection.

To clear the stored values and begin a new cycle of monitoring

endpoints, just press the

F1

and

F2

keys

simultaneously

. When

turn off, the digital panel meter this information is not saved.

CUSTOM LINEARIZATION

This feature allows accurate measurement of the input signals with

non-linear features.

Linearization consists in dividing the calibration curve of the input

signal into segments of variable gain. Each segment consists of a

start and an end. For each input value (

Inp

.xx), a respective output

indication (

ovP

.xx) is defined.

The input signal must present an always-crescent.

Applied to 0-20 mA, 4-20 mA, 0-50 mV, 0-5 V and 0-10 V input types.

24 VDC AUXILIARY VOLTAGE SOURCE

The standard version of the

N1540

provides an auxiliary power

supply for exciting field transmitters (terminals 11 and 13 on the rear

panel).

SERIAL COMMUNICATION

Follows a description of the usual communication registers. For full

documentation, download the

Registers Table N1540 for Serial

Communication

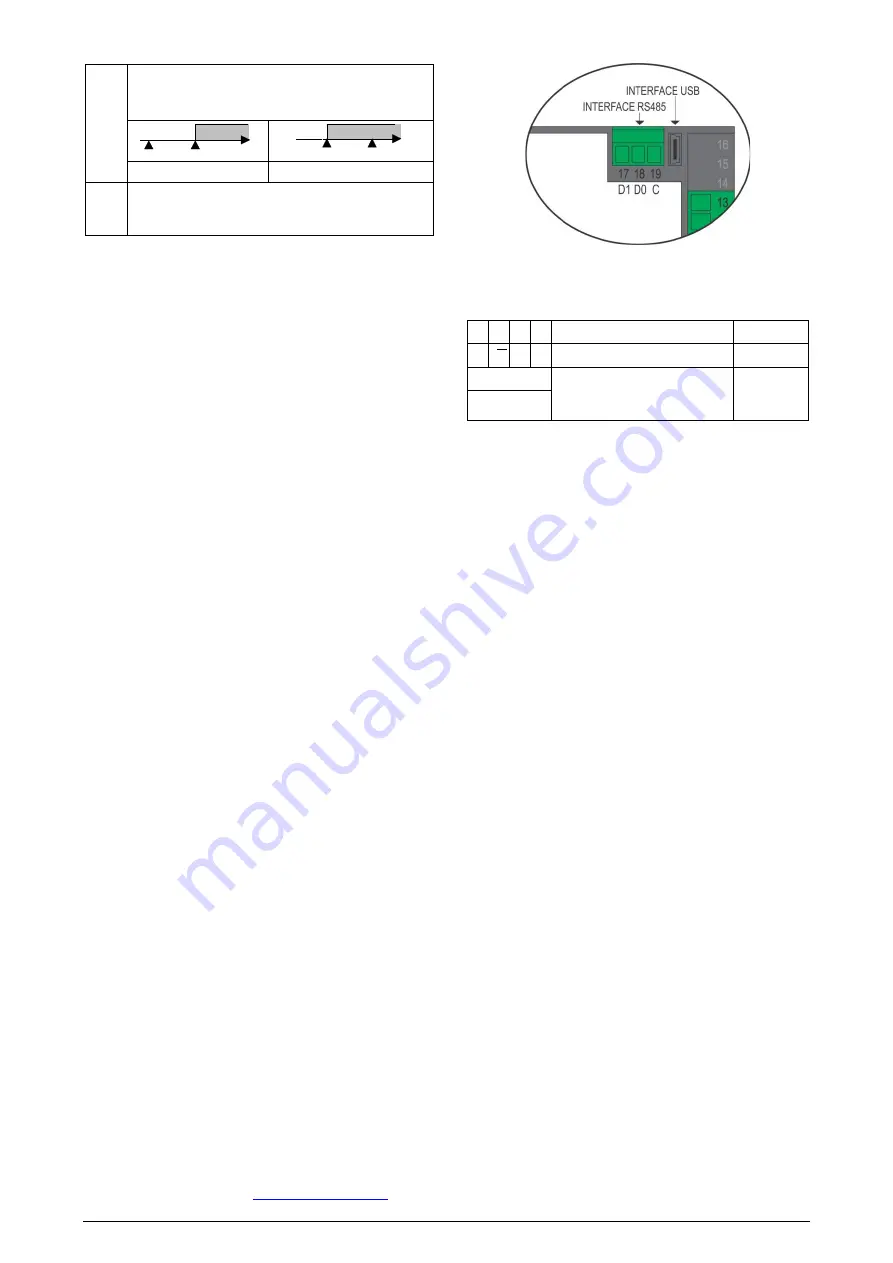

Figure 1 –

Serial communication

RS485 INTERFACE: ELECTRICAL CONNECTION

The RS485 signals are:

D1 D D + B

Bidirectional data line.

Terminal 17

D0

𝑫𝑫

D - A

Inverted bidirectional data line.

Terminal 18

C

Optional connection that

improves the communication

performance.

Terminal 19

GND

Table 3 –

RS485

USB INTERFACE

The USB interface is used to CONFIGURE, MONITOR or UPDATE

the controller FIRMWARE. The user should use

QuickTune

software, which offers features to create, view, save, and open

settings from the device or files on the computer. The tool for saving

and opening configurations in files allows the user to transfer settings

between devices and perform backup copies.

For specific models,

QuickTune

allows to update the firmware

(internal software) of the controller via the USB interface.

For MONITORING purposes, the user can use any supervisory

software (SCADA) or laboratory software that supports the Modbus

RTU communication over a serial communication port. When

connected to a computer USB, the controller is recognized as a

conventional serial port (COM x).

The user must use

QuickTune

software or consult the DEVICE

MANAGER on the Windows Control Panel to identify the COM port

assigned to the controller.

The user should consult the mapping of the Modbus memory in the

controller communication manual and the documentation of the

supervision software to start the MONITORING process.

Follow the procedure below to use the USB communication of the

device:

1.

Download

QuickTune

software from our website and install it on

the computer. The USB drivers necessary for operating the com-

munication will be installed with the software.

2.

Connect the USB cable between the device and the computer.

The controller does not have to be connected to a power supply.

The USB will provide enough power to operate the communica-

tion (other device functions may not operate).

3.

Run the

QuickTune

software, configure the communication and

start the device recognition.