NOVUS AUTOMATION

1/7

N1030T Controller

TEMPERATURE CONTROLLER AND TIME – INSTRUCTIONS MANUAL – V1.0x A

SAFETY ALERTS

The symbols below are used on the equipment and throughout this

document to draw the user’s attention to important operational and

safety information.

CAUTION:

Read the manual thoroughly

before installing and operating

the equipment.

CAUTION OR DANGER:

Electrical shock hazard

All safety related instructions that appear in the manual must be

observed to ensure personal safety and to prevent damage to either

the instrument or the system. If the instrument is used in a manner not

specified by the manufacturer, the protection provided by the

equipment may be impaired.

INSTALLATION / CONECTIONS

The controller must be fastened on a panel, following the sequence

of steps described below:

•

Prepare a panel cut-out of 46 x 46 mm;

•

Remove the mounting clamps from the controller;

•

Insert the controller into the panel cut-out;

•

Slide the mounting clamp from the rear to a firm grip at the panel.

RECOMMENDATIONS FOR THE INSTALLATION

•

All electrical connections are made to the screw terminals at the

rear of the controller.

•

To minimize the pick-up of electrical noise, the low voltage DC

connections and the sensor input wiring should be routed away

from high-current power conductors. If this is impractical, use

shielded cables. In general, keep cable lengths to a minimum.

•

All electronic instruments must be powered by a clean mains

supply, proper for instrumentation.

•

It is strongly recommended to apply RC'S FILTERS (noise

suppressor) to contactor coils, solenoids, etc. In any application it

is essential to consider what can happen when any part of the

system fails. The controller features by themselves can not

assure total protection.

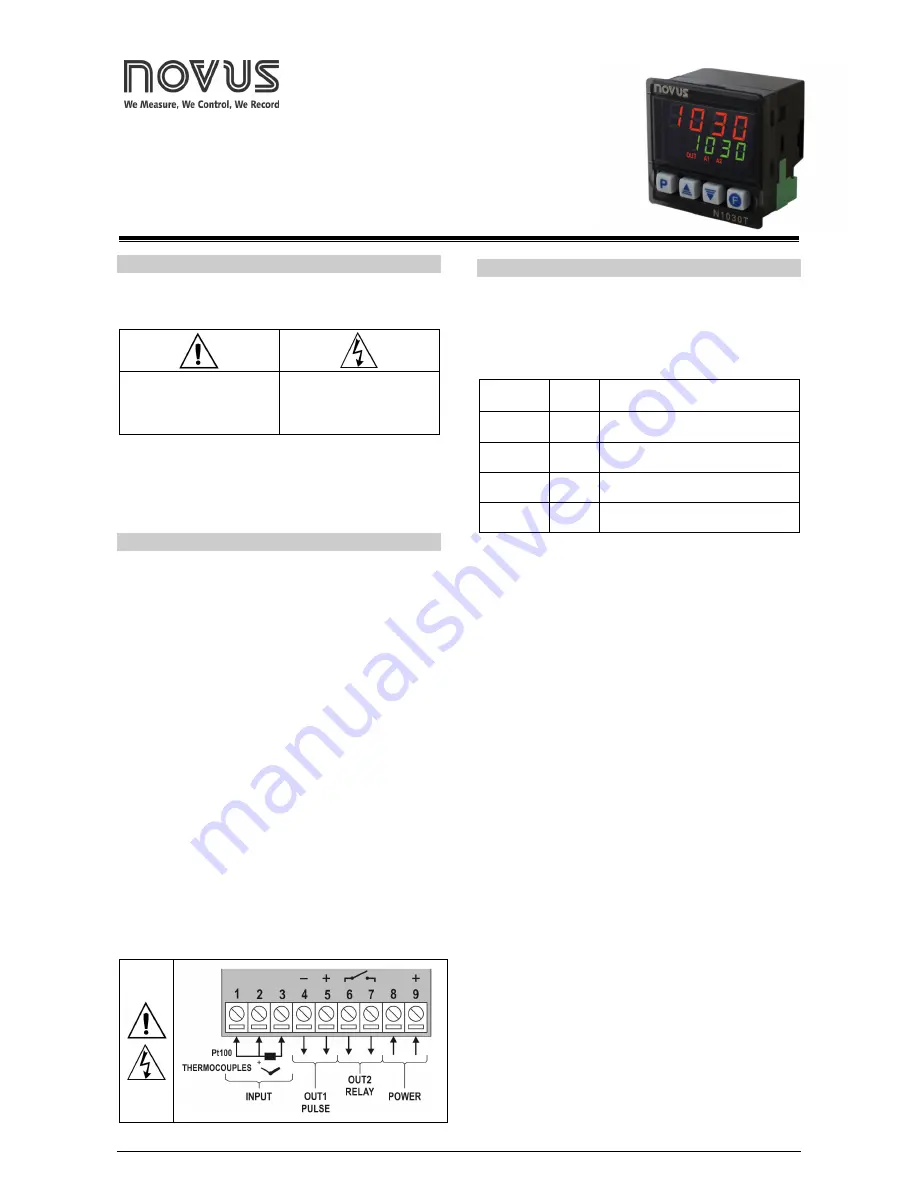

ELECTRICAL CONNECTIONS

Fig. 01

below shows the electrical terminals of the controller:

Fig. 01

- Connections of the back panel

FEATURES

INPUT SINGNAL (INPUT)

The type of input to be used by the controller is defined in the

equipment configuration.

Table 01

displays the input options

available to the user, one of which must be selected during the

controller configuration

.

TYPE

CODE

RANGE OF MEASUREMENT

Termocouple

J

Tc j

Tc j

Tc j

Tc j

Range: -110.0 a 950.0 °C (-166.0 a 1742 °F)

Termocouple

K

Tc k

Tc k

Tc k

Tc k

Range: -150.0 a 1370 °C (-238.0 a 2498 °F)

Termocouple

T

Tc t

Tc t

Tc t

Tc t

Range: -160.0 a 400.0 °C (-256.0 a 752.0 °F)

Pt100

Pt

Pt

Pt

Pt

Range: -200.0 a 850.0 °C (-328.0 a 1562 °F)

Table 01

– Input types

The temperature sensor used should be the first information passed

onto the controller. A change in this parameter may imply automatic

changes to many other parameters. The user must check the general

condition of the configuration whenever an exchange of the sensor

type is held.

OUTPUTS

The controller offers two output channels: OUT1 and OUT2. Their

electrical characteristics are:

OUTPUT

OUT1

- Logical pulse, 5 Vdc / 25 mA

OUTPUT

OUT2

- Output Relay SPST-NA / 1,5 A / 240 Vac

The output channels are user configurable as

Control Output

,

Alarm Output

or as

Output Timers T1

or

T2

.

CONTROL OUTPUT (

(TRL

(TRL

(TRL

(TRL

)

The process control output can operate in

ON/OFF

mode or in

PID

mode.

To operate in

ON/OFF

mode, the value defined in the parameter

PB

PB

PB

PB

should be

0.0

.

With values other than zero in the

PB

PB

PB

PB

parameter, the controller

operates in the

PID

mode. The PID parameters can be automatically

determined enabling the auto-tuning function (

ATvN

ATvN

ATvN

ATvN

).