User Manual

ALX 92x

09/2016 | 00

80

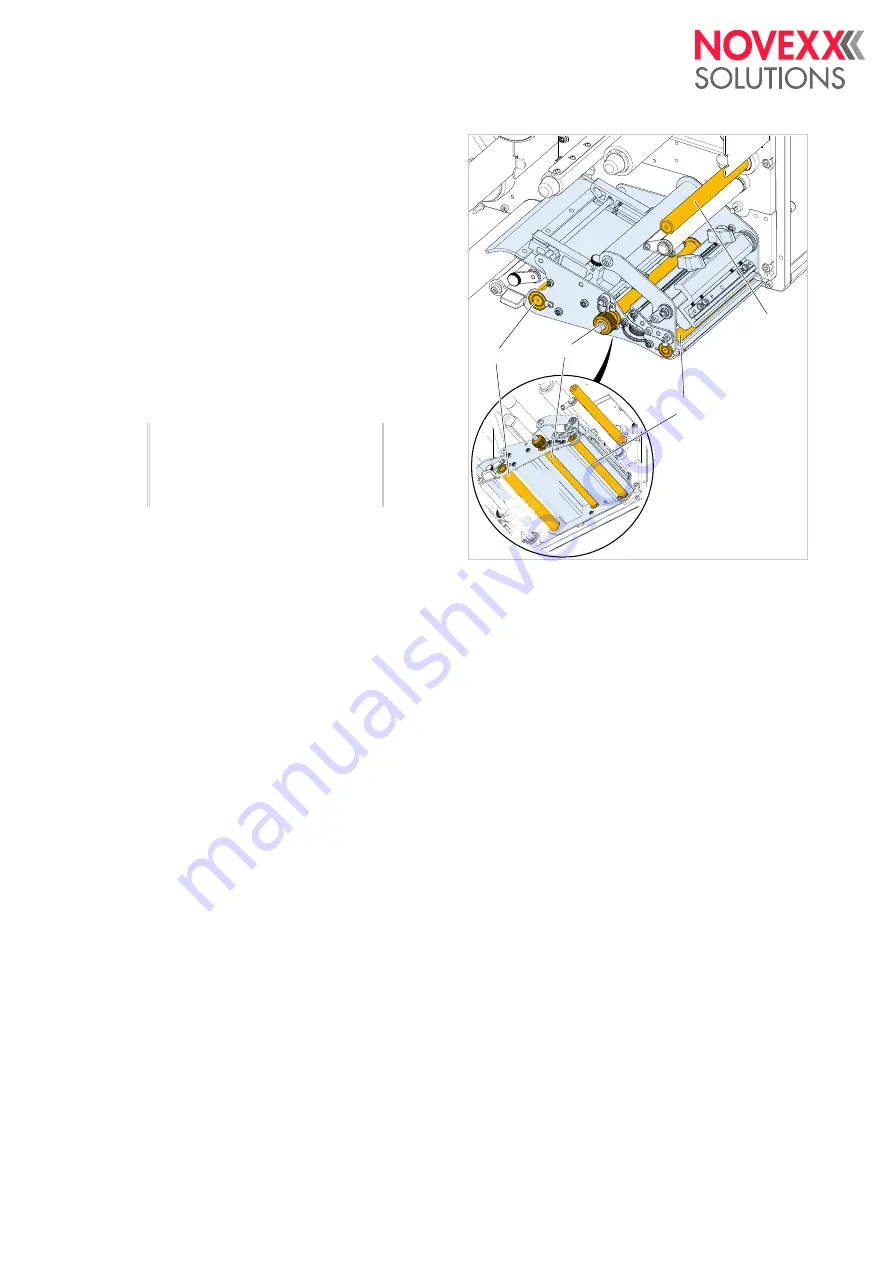

RUBBER ROLLERS

The rubber rollers on the ALX 92x can be cleaned from

the bottom of the machine without any additional as-

sembly work. The ribbon roller is freely accessible while

the cover is open and the ribbon is removed [68].

Cleaning the rollers:

1. Switch off the machine.

2. Remove the mains power connecting line.

3. Remove the material and/or ribbon.

4. Wipe off the rollers with a dust-free cloth and roller

cleaner.

Rotate the roller step for step until it is complete-

ly clean.

It is also possible to clean the print roller from the

front. To do this remove the printhead.

See

CAUTION!

Danger of damaging the roller.

Never use knives or sharp objects

to clean the rollers!

[68] Positions of the rubber rollers:

A

Print roller

B

Brake roller

C

Feed roller

D

Ribbon feed roller

A

B

C

D

Summary of Contents for ALX 924

Page 2: ......

Page 6: ...User Manual ALX 92x 09 2016 6 Content...

Page 90: ......

Page 91: ...Novexx Solutions GmbH Ohmstra e 3 85386 Eching Germany 49 8165 925 0 www novexx com...