LASER DESIGN

PAGE

|

59

Laser Design

Optical resonator

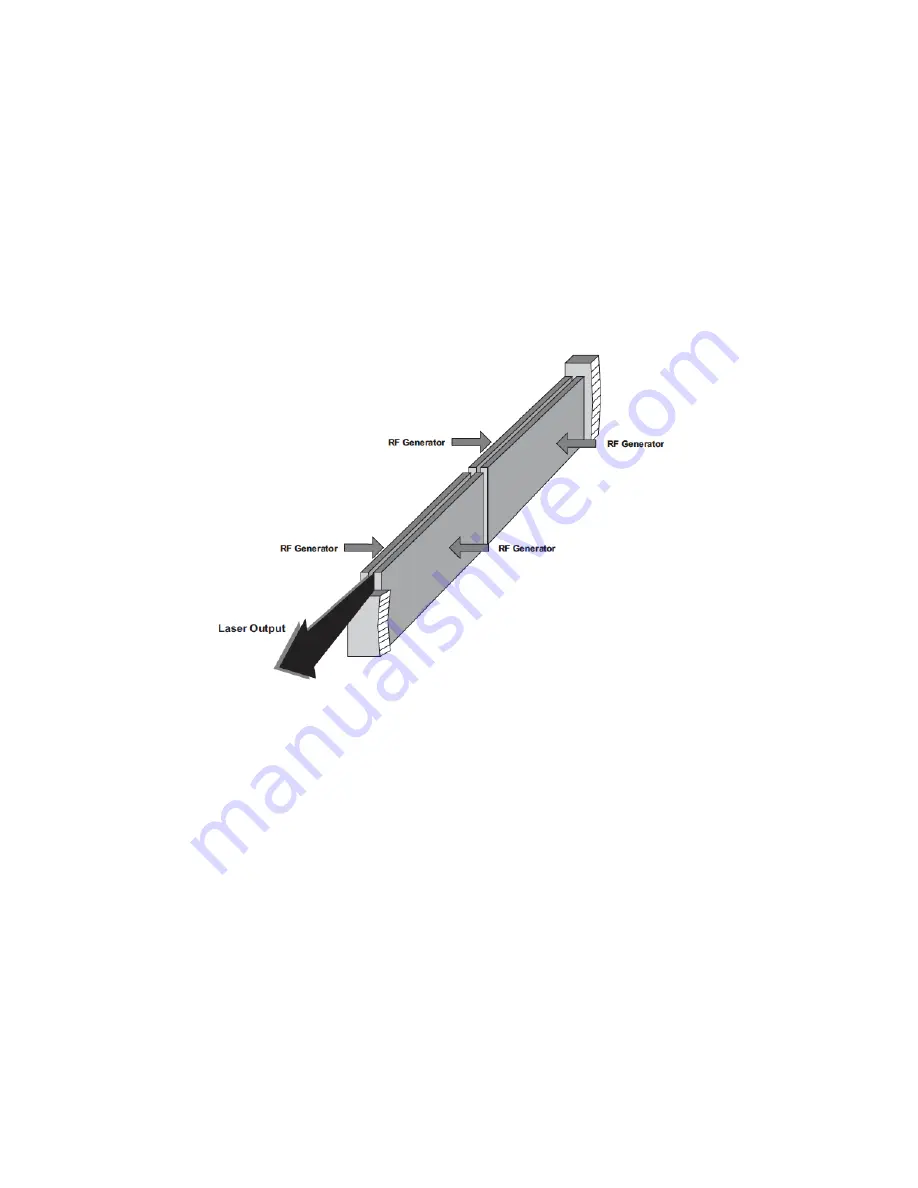

i401 lasers were developed using new technology developed by Novanta, Inc. This new technology,

based on a hybrid waveguide/unstable resonator design (Figure 3-1), enables Novanta to economically

produce a symmetrical laser beam from a small

but powerful laser capable of operating for many

years

with virtually no maintenance. I401’s unique extruded aluminum envelope offers excellent heat transfer,

long gas life, and low operating costs in contrast to other laser tube technologies. Besides being the

vessel that maintains the lasing environment, the aluminum tube is also the structural platform that

integrates the laser’s optical, electrical, and cooling components.

Figure 4-1 Hybrid waveguide/unstable resonator design

The optical resonator, in conjunction with the electrodes and the gas mixture, generates the laser beam.

I401 optical resonators are comprised of three optical elements: a front mirror, a rear mirror, and an

output window. These optical elements are fastened to the tube’s exterior and are exposed to its interior

through holes in the end caps. O-rings are sandwiched between optical elements and the end cap to

form a gas seal and to provide a flexible cushion that allows the slight movement necessary for

alignment. All optical elements are aligned and locked into place by factory technicians before the laser

is shipped.

The structure of the resonator and internal beam conditioning optics combine to produce a near Gauss-

ian mode quality (M

2

factor) of < 1.2. Beam waist diameter is typically 6.7 mm at the output aperture and

full-angle divergence due to diffraction is approximately 2.5 milliradians (a 2.5 mrad divergence means

that beam diameter increases 2.5 mm over every one-meter distance traveled). Beam ellipticity

measures approximately < 1.2 as it exits the resonator but becomes closer to 1.0 in the far field (or at the

point of focus) as shown in Figure 3.2.