Operating instructiOns 8264

8

2018-09-12

safeTy

Application

Never use the machine for material which is outside the capacity range of the machine. Check

the machine plate and the section “Technical data”.

Before the machine is operated the following steps must be taken:

Check that all safety devices function and that they are not damaged. Also check that moveable parts

are not exposed to obstacles e.g. owing to incorrectly mounted guards or parts. Broken parts or safety

components must be changed by authorized staff. Contact Nosstec in case spare parts are needed. The

machine has a 24 month applicable warranty from date of delivery.

Check that the environment around the machine is suitable.

• Do not expose the machine to rain.

• Do not use the machine in wet or damp premises.

• Check that the lighting of the premises is satisfactory.

• The floor must be clean, dry and free from oil and grease spots.

• Never use easily inflammable material close to the machine.

• Dirty working sites increase the risk of accidents.

Position of top roll

The top roll must never be in the swung-out position when the machine is in operation.

Avoid unstable working positions

Check that the operator always has a secure and stable working position. When prebending the opera-

tor must stand on the reverse side of the machine.

Do not keep tools on the machine

Remove all tools from the machine before it is operated.

All repairs must be carried out by authorized staff

The machine and its electrical equipment has been made according to valid safety rules. All

repairs must be carried out by trained and qualified staff. Only original spares must be used.

Note: If the repairs also involve dismantling of the machine, this must be carried out

according to the enclosed dismantling instruction. This instruction must not be kept

together with the machine.

Summary of Contents for 8264

Page 1: ...Bending Roll Machine 8264 Operating Instructions...

Page 2: ......

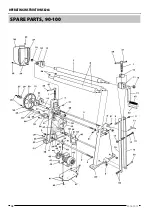

Page 17: ...8264 English rev 3 17 Spare parts 80 90...

Page 18: ...Operating Instructions 8264 18 2018 09 12 Spare parts 90 100...

Page 19: ...8264 English rev 3 19 Spare parts 100 110...

Page 20: ...Operating Instructions 8264 20 2018 09 12 Spare parts 120 130...

Page 23: ......